pan

A pan or frying pan (from Middle High German phanne, from Old High German phanna , which goes back (like Middle Low German panne ) from folk Latin panna to Latin patina “bowl, pan” and Greek patánē (πατάνη) “bowl”) is a metal cooking device that is used for frying . Compared to the pot , the pan is shallower. An intermediate form, the casserole . By the flatter shape, it is possible the food to in a pan with a spatula to turn. Due to the larger surface area in relation to the volume, liquid is reduced more quickly than in a pot of the same volume. In Swiss High German , saucepans, especially saucepans, are also referred to as pans . From a certain size and with pottery made of ceramics, one speaks of a pot in Switzerland. A shallow pan in the sense described here is often called a frying pan. Tall pans are known as braising pans. Pans with a grooved profile in the bottom are grill pans. One differentiates between pans based on their basic material, their surface and their shape.

materials

Non-stick coating

- Thermoplastic non-stick coating Pans with a thermoplastic non-stick coating, often called Teflon pans , are usually made of aluminum . The coatings usually contain polytetrafluoroethylene (PTFE, often also known under the trade name Teflon ), sometimes with the addition of the auxiliary PFOA , which can evaporate when the pan is overheated and is considered carcinogenic. The coatings are offered under a variety of brand names. The sensitive surface wears with the use of metal cutlery faster and can by heating above 260 ° C may be damaged. At even higher temperatures of around 300–450 ° C, the coating can burn and emit toxic combustion products, which in rare cases can cause so-called polymer fever (also known as Teflon fever ). Aluminum pans with coating damage (edges, base, but also scratches) are no longer dishwasher-safe because the metal is attacked by the more aggressive cleaning agents. It is true that a protective oxide layer forms , which is initially only visually negative. However, scratches on the inside of the pan can encourage pitting corrosion . Due to their temperature resistance weaknesses and their insufficient heat storage capacity, PTFE-coated aluminum pans are only suitable to a limited extent for searing , because when the food is loaded, the temperature drops too much, which leads to the escape of water, which reduces the temperature through evaporation, see above that no Maillard reaction can take place. A common misconception is that the invention of the Teflon coating is a by-product of space travel . Instead, Teflon was first used to enrich uranium .

- Enamel coatingAn enamel coating primarily serves as a protective coating. It prevents corrosion and the reaction of the food with the base material of the pan. Like the ceramic non-stick coating, enamel contains silicon as a main component, but in a completely different chemical composition and not as a thin layer , but in the form of a glass-like, smooth and pore-free coating. This enables easy cleaning. The frying behavior of an enamel-coated pan is similar to that of a stainless steel pan. A dark inner surface is important, as the heat is optimally transferred through it.

- Silargan pans Silargan is a ceramic coating for pots and pans. This type of coating is based on silicon dioxide , its thickness is in the micrometer range (thin layer). The high-tech ceramic is inseparably fused with the (ferromagnetic) steel body of the cookware. Ceramic non-stick coatings can be heated to over 400 ° C without the coating being damaged and are more resistant to mechanical damage. Silargan pans are easy to clean and suitable for almost all types of stoves. They are suitable for both spicy searing and braising.By overheating of frying fats ceramic non-stick coatings lose relatively fast their non-stick properties . Pan manufacturers therefore advise against the use of non-heatable, mostly cold-pressed oils. A burnt-in layer of fat that can hardly be removed forms on the smooth surface. The pans can still be used, but with a decreasing non-stick effect. Compare pictures in the following link: contact angle .

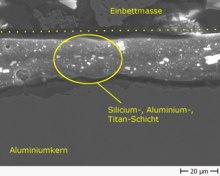

- Titanium pans If a ceramic spray layer made of an aluminum-titanium mixed oxide (typically Al 2 O 3 -TiO 2 97/3 or 87/13) is applied under the non-stick coating , they are also known as titanium pans. This intermediate layer increases the scratch resistance. Such a pan can be seen in the scanning electron microscope in the illustration on the right . The approximately 0.68 μm thick aluminum-titanium mixed oxide layer rests on the aluminum core of the capsule base . The dark area between the two layers just contains more titanium than aluminum.

aluminum

Aluminum pans are made by deep drawing from sheet metal, in permanent mold casting or in the squeeze casting process. Because of the good thermal conductivity of aluminum, no multilayer structure is required. However, if you also want to cook on an induction hob, the base must also be ferromagnetic .

stainless steel

Pans made of stainless steel alloyed with chrome and nickel are heavier but also more robust. They are not as easy to care for as Teflon pans because they are mostly uncoated.

However, stainless steel is a poor conductor of heat (about 15 times worse than aluminum and 25 times worse than copper). To counteract this, the bottom of the pan consists of several layers. It is also known as a sandwich floor or a thermal floor. It consists of a layer of stainless steel, a - in relation to stainless steel - thicker layer of aluminum (or copper) and another layer of stainless steel. If the sandwich base (open on the sides) is encased with additional stainless steel, one speaks of an encapsulated thermal base or capsule base .

maintenance

Stainless steel pans are cleaned with normal detergent. Any adhesions are left to soak. (Stuck residues are usually a sign of incorrect frying technology, such as food that has been turned too early.) Very often whitish toppings are found after drying. These can be easily removed with a few drops of vinegar or lemon juice. Finally rinse with water. If you use sponges for cleaning, you should make sure that the scouring side is "scratch-free", ie it does not contain hard particles such as quartz or corundum . The same applies to other abrasives. In contrast to uncoated iron pans, which are specifically intended to be burned in, it is not advisable to rub stainless steel pans with kitchen paper only.

cast iron

Cast iron pans with a smooth base are suitable for all types of stoves. Cast iron has a thermal conductivity that is up to four times higher than that of stainless steel. Since the walls of cast iron pans are quite thick, the pans are very heavy and take a relatively long time to get hot. But then they keep the heat well and, intensely preheated, are good for searing and braising. A protective layer burns into the bottom of the pan. This patina prevents rust when not in use. In addition to pans made of raw cast iron, enamelled completely or only on the inside or outside are common.

Wrought iron

Professional chefs' frying pans are often made of forged iron . A disadvantage compared to the coated aluminum pan is its heavy weight. Iron pans are suitable for all common stoves. However, the bottom can warp with improper use, for example if the hotplate is smaller than the bottom of the iron pan. Iron pans are also suitable for use over an open fire.

In the development process, a distinction can be made between cold- formed and hot-formed pans. The hot deformation often occurs even in traditional craftsmanship in so-called hammer mills , but also by industrial forging . The steel is processed red-hot in the hot process.

Manufacturing

While iron pans were still driven with a hammer in ancient times, since the beginning of industrialization mostly mechanical, electrical or predominantly hydraulic presses have been used for the efficient production of pan bodies from sheet steel . A punched sheet metal disc a few millimeters thick is pressed into a deep-drawing mold under high pressure. This process is called deep drawing in technical terms . The result is pan bodies with a wall thickness of preferably 1.5 to 5 mm, depending on the size of the pan. Another traditional method is metal spinning , where a rotating disc is pressed over a negative mold on a spinning machine. Drop forging is the term used for hot forming of the glowing semi-finished product. These pans enjoy the best reputation today. The Lyonese form is probably best known . It is characterized by the slightly bulbous side walls for easier turning of the food. In France , this pan shape is still partly made with the old machines.

maintenance

Before using for the first time, iron pans must be burned in once. This is done (after removing the corrosion protection) with highly heatable frying fat, salt and raw potato slices or peels until both the potatoes and the bottom of the pan have turned a deep dark brown to obtain a starchy layer. This takes at least 10 minutes and is finally allowed to smoke. The pan is then rinsed with hot water and dried. The baking process does not end until the layer has dried.

After baking, the iron pan has similar non-stick properties as coated pans, but it cannot do without adding fat. The adhesion-reducing effect increases over time due to the build-up of a patina .

After each use, iron pans are rubbed with kitchen paper and, if necessary, salt. The pan should always be lightly rubbed with oil for storage.

With the right frying technique, stubborn buildup practically does not occur. The most common mistake, in addition to turning the food too early, is the wrong frying temperature. Because preserving the patina is of key importance, the correct frying technique is an important maintenance measure. In both wrought iron and cast iron pans without enamel, the food comes into direct contact with the metal. Therefore, the food must not be stored in the pan after frying. Because chemical reactions with the food would leach iron out of the pan, which would lead to undesirable corrosion .

copper

Copper has a thermal conductivity that is only surpassed by silver among metals . As a result, the heat brought in by the stove is quickly distributed in the bottom of the pan and a particularly even temperature is set. It is commonly found in French kitchens. Copper pans are usually used on gas stoves to take advantage of their good thermal conductivity. For some years now there have also been copper pans that are suitable for induction cookers. Since copper can react with certain foods, copper pans are either tinned on the inside , clad with stainless steel or, for example, non-stick coated with a ceramic seal .

to form

Many forms have special names:

- Lyonnaiser shape

- Rounded transition between the bottom and the edge.

- Fish pan

- Is oval to match the shape of a whole fish.

- Crepes pan

- Has a very flat edge and is therefore particularly suitable for crêpes and pancakes .

- Egg pan

- Is a round or square pan with several circular recesses for one egg each. This pan was already used in the Middle Ages to bake eggs in lard . It can also be used to bake special pastries, e.g. B. for Dalken .

- Bliný pans

- Very similar to the egg pans, but only about 12 cm in diameter.

- Paella pan

- The so-called paellera for paella is often very large and has two opposing metal handles. It is usually used on an open fire.

- Snail pan

- Is a round pan with several spherical depressions. It is often made of ceramic material because it is primarily intended for use in the oven. If these pans are made of cast aluminum or cast iron, they are mostly used on the stove for dough balls such as wickets, donuts or ox eyes.

- Poffertjes pan

- For flat, small dough cakes with a diameter of approx. 5 cm. Often heated by an air cushion without direct contact with the stove top.

- Steak pan

- Also known as the grill pan, it has a ribbed inner base, with which you can quickly and attractively achieve the appearance of the food grilled on a wire rack. It makes it possible to create areas of strong browning and also not to increase the internal temperature of the food too much, thus keeping the loss of liquid relatively low.

- Roasting pan

- Both round and rectangular with two handles. Suitable for stove and oven.

- Wok

- Asian high, fully domed pan. This will concentrate the heat in the middle. The preparation is typically done with a very high energy supply, whereby the food to be fried comes to the center again and again, but only briefly. The cooking times are also short overall. The classic spherical shape is only suitable for open fire or special wok burners (if possible> 5 kW). For common kitchen stoves, the hob surface is flattened. A curved inner shape is possible for cast iron and cast aluminum woks. Other materials have a flat bottom and a steeper rim on the inside, which limits the function of the wok.

- Tilting frying pan

- The tilting frying pan can be found in large kitchens. It is connected to the heater and can be tilted manually or electrically so that the contents of the pan slide forward. It is provided with an outlet for precise pouring; this also enables the pan to be emptied completely without any problems. Tilting frying pans are mainly used to prepare large roasts, short roast dishes and meat sauces and are available in sizes up to 100 liters. The energy consumption of tilting frying pans is higher than that of generally closed cooking appliances such as combi steamers .

- Makiyakinabe

- Japanese rectangular or square omelette pan.

- Serving pans

- Usually with two compact handles. For serving and braising, usually oven-proof; sometimes just made of thin-walled material.

Pan in music

Ordinary metal pans can be used as a percussion or sound instrument. In the music of the Roma in the Balkans , women cultivate a traditional style of singing that is distinct from the brass music of men and that does not use melody instruments . Either a frame drum ( daf ) or a copper pan (tepsia) serve as rhythmic accompaniment . In the singing style called Tepsijanje , the women turn an upright pan on a round table (sofra) in a circle, so that a constant noise is created.

Web links

Individual evidence

- ^ Friedrich Kluge , Alfred Götze : Etymological dictionary of the German language . 20th edition. Edited by Walther Mitzka , De Gruyter, Berlin / New York 1967; Reprint (“21st unchanged edition”) ibid 1975, ISBN 3-11-005709-3 , p. 541.

- ↑ Ulrich Ammon, Hans Bickel, Jakob Ebner, et al .: German dictionary of variants . The standard language in Austria, Switzerland and Germany as well as in Liechtenstein, Luxembourg, East Belgium and South Tyrol . Walter de Gruyter, Berlin 2004, ISBN 3-11-016575-9 , p. 568.

- ↑ DJ Shusterman: Polymer fume fever and other fluorocarbon pyrolysis-related syndromes . In: Occupational Medicine (Philadelphia, Pa.) . 8, No. 3, July 1, 1993, ISSN 0885-114X , pp. 519-531. PMID 8272977 .

- ↑ K. Toyama, K. Kimura et al. a .: Case of lung edema occurring as a result of inhalation of fumes from a Teflon-coated flying pan overheated for 4 hours. In: Nihon Kokyuki Gakkai Zasshi = the journal of the Japanese Respiratory Society. Volume 44, Number 10, October 2006, pp. 727-731, ISSN 1343-3490 . PMID 17087340 .

- ↑ Shimizu T, Hamada O, Sasaki A, Ikeda M: Polymer fume fever . In: BMJ Case Rep . 2012, December 2012. doi : 10.1136 / bcr-2012-007790 . PMID 23230259 . PMC 4544973 (free full text).

- ^ Richard Rhodes : The Making of the Atomic Bomb . Simon and Schuster, New York, New York 1986, ISBN 0-671-65719-4 , p. 494.

- ↑ Dr Christopher H. Phillips: Thermolon ™ Mineral Coatings. (No longer available online.) October 2010, archived from the original on February 19, 2018 ; accessed on July 12, 2017 (English). Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Birgit Rademacker; Maike Jessen: 1 pan - 50 recipes . Ed .: Munich Gräfe and Unzer 2007. ISBN 978-3-8338-0654-4 , pp. 64 .

- ↑ Svanibor Pettan: "Male" and "Female" in Culture and Music of the Roma in Kosovo. (Draft) Music as representation of gender in Mediterranean cultures, Venice, 11. – 13. July 1998.

- ^ Franz Födermayr , Werner A. Deutsch: On the acoustics of the "Tepsijanje" . In: Max Peter Baumann , Rudolf Maria Brandl, Kurt Reinhard (eds.): Festschrift for Felix Hoerburger for his 60th birthday. Laaber, Laaber 1977, pp. 97-112.