M829

The 120 mm M829 balancing ammunition made from depleted uranium is the primary ammunition of the M1 Abrams main battle tank for combating heavily armored targets. The original version of the bullet was a first-generation impact bullet; newer versions are classified as second and third generation due to their improved properties. The bullet penetrates armor due to its high kinetic energy, it does not contain explosives. According to the US Army , an M829 projectile can penetrate the front armor of any armored vehicle.

Development history

The development of the M829 ammunition goes back to tests by the US Army with sub-caliber projectiles for the 105 mm M68 cannon in December 1977. The result was that by increasing the length / diameter ratio from 15.5: 1 to 18: 1 while maintaining the penetrator caliber of 24 mm, a significantly better penetration rate was achieved. This basic knowledge was used to develop two projectiles: the XM829 for 120 mm smoothbore cannons and the XM833 for the existing 105 mm drawn barrel cannons. After the decision to replace the 105 mm gun of the M1 with a license production of the Rheinmetall 120 mm smoothbore gun, the first examples of the XM829 with a tungsten core were tested in Germany in July 1979 . Despite the occasional failure of the core at high temperatures, high penetration rates were achieved.

The American 120mm program was almost complete in 1984 and pre-series production began. This year, the technology transfer was also successfully demonstrated when the Watervliet Arsenal produced 31 weapons systems and 56 tubes of the Rheinmetall cannon as XM256 under license. The DM 13 projectile was adopted in the US designation as XM827, with tungsten as a heavy metal insert being replaced by depleted uranium. Ultimately, it was decided to focus on the XM829 bullet, as it had a better length / diameter ratio; the propellant was taken over by Rheinmetall DM 13 and the tungsten core was replaced by depleted uranium. After completing the tests in Panama and on the Aberdeen Proving Ground , a few small changes were made, after which series production began for 8,500 units. Shortly afterwards, series production of the M1A1 Abrams began in August 1985. The most important innovation was the replacement of the 105 mm M68 cannon with the license-made M256. The KE training bullet DM 38 was modified for training purposes and put into service as the M865.

At the end of the 1980s, an improved version followed with the M829A1 to keep pace with the further development of composite armor . When, after the end of the Cold War, the Bundeswehr subjected T-72 tanks from the inventory of the National People's Army to fire tests, this gave the impetus for the development of the M829A2 version. According to Leland Ness of Jane's Information Group , the M829 projectiles of the 120 mm L / 44 smoothbore cannon could not penetrate the frontal armor of the vehicles when they were equipped with Kontakt-5 reactive armor. The reason is probably the uranium core of the projectile itself, since the flexural modulus of uranium is three times lower than that of tungsten and reactive armor exerts a shear load on the thin, long projectile. Countries like China, France or Russia therefore use both uranium and tungsten etchers. The M829A2 represents the largest development step in the ammunition family and was introduced in 1992/1993. The currently produced version M829A3 followed only 10 years later, has a new propellant powder and meets the requirements for insensitive ammunition .

overview

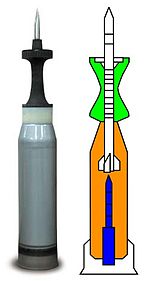

The typical structure of an M829 cartridge is shown in the picture on the right. The lower part consists of the steel sleeve stub (white) and the high-energy propellant in the combustible sleeve (orange). In the middle is the propellant charge lighter (blue), which ignites the propellant and determines its burning behavior. The bullet itself (white) is guided through the smooth tube by the sabot (green); a nylon guide tape is used for sealing . After leaving the muzzle, the sabot is thrown off. The projectile consists of a ballistic hood at the tip, the penetrator in the middle and the tail unit at the end, which contains a pyrotechnic charge . Since the M829 ammunition was designed according to STANAG 4385 , it can be fired by all 120 mm smoothbore cannons.

Versions

M829

The original version, which was manufactured from 1984 after development was completed. Since the development ran parallel to the XM833 bullet for the 105 mm drawbar cannons, the structure of both bullets will be identical. The bullet itself has a hardened steel tip and a cylindrical body made of maraging steel , which is filled with a uranium alloy. The alloy developed at Los Alamos National Laboratory consists of 99.25% depleted uranium and 0.75% titanium, and was originally developed for the GAU-8 / A Avenger . The addition of titanium prevents cracks from forming when the material is processed and improves the possibilities for heat treatment and corrosion resistance. With a length / diameter ratio of 18: 1 and a diameter of 24 mm, the bullet length is 432 mm. To stabilize the flight path, the penetrator is equipped with a six-wing aluminum tail unit, which, like the four-part sabot, is made of aluminum 7075-T6. The propellant charge is identical to the German DM 13 and uses JA2 bulk powder. It is ignited by an M125 propellant charge lighter developed in the USA. The propellant powder JA2 consists of 59.02% cellulose nitrate , 24.6% diethylene glycol dinitrate , 14.78% nitroglycerin , 0.7% methyldiphenylurea (Akardit II), and 0.5% each of barium oxide and graphite . This version is no longer produced.

M829A1

A version with slight improvements and a much longer penetrator, the introduction into the troop service took place at the end of the 80s. The four-part sabot was replaced by a three-part guide cage made of an aluminum alloy. The length / diameter ratio was increased to about 31: 1. The diameter of the penetrator was reduced to 22 mm while its length increased to about 684 mm. The bullet length increased to 780 mm. The perforated JA2 propellant powder is ignited by the modified M129 propellant lighter. To protect against environmental influences, the cartridge is transported in a closed steel cylinder with the designation PA116 from Conco, which is zinc-phosphated for corrosion protection and insulation reasons . Due to the high penetration rate of the bullet in the Second Gulf War, the tank crews nicknamed it Silver Bullet (a play on "silver bullet" and "perfect problem solver").

M829A2

Greatly improved version, also known as Super Depleted Uranium (SDU) penetrator in trivial literature . The introduction into the troop service took place in 1992/1993, as a reaction to the Bundeswehr bombardment attempts of T-72 tanks with Kontakt-5 reactive armor. According to several sources, a new manufacturing process for the DU penetrator will be used to improve its "structural quality". Presumably, a change was made to a monoblock design, with the dimensions of the projectile and the six-wing aluminum tail unit remaining roughly the same. The Los Alamos National Laboratory developed a tungsten-uranium alloy as early as 1989, which compared to the uranium-titanium alloy had a 25% higher modulus of elasticity and a yield strength of over 400% . The powder mixture is forged into shape at around 1350 ° C and, in contrast to the more brittle uranium-titanium alloy, does not require any heat treatment during forging. The mixing ratio can be estimated at about 1: 1 based on published sectional images . The significantly increased yield strength would also make the penetrator more resistant to the shear stress that reactive armor exerts on the thin, long projectile. Because of the tungsten, the alloy would also have a greater density than typical uranium ammunition made from a uranium-nickel-zinc alloy. For the first time in an APFSDS bullet, the four-part sabot was made from carbon fiber reinforced plastic . The matrix consists of an epoxy resin , the component is presumably manufactured using the transfer molding process. The JA2 propellant charge consists of a combination of rod and bulk powder and is ignited by an M129 propellant charge lighter.

M829A3

The M829A3 has been in production since March 2003. Little is known about the projectile. According to the manufacturer, the projectile weight should have increased from 7.9 kg in the M829A2 to 10 kg, which suggests a heavier penetrator. The aim was to reduce the parasitic weight of the sabot by 20% and to increase the muzzle velocity by 10% compared to the M829A2. The newly developed RAIL (Rapid Automated Induction Lamination) process was used to manufacture the guide cage: The CFRP laminate impregnated with the thermoplastic polyetherimide (PEI) is first heated using a resistance heater. In the next step, the laminate is brought to processing temperature by induction heating and then placed in a die . There it is shaped and cooled so that the composite falls below the glass transition temperature and the component solidifies. In addition, the cartridge has a more effective, rod-shaped propellant powder with the designation RPD-380, which is ignited by the propellant charge lighter M123A1. RPD-380 consists of approximately 59% cellulose nitrate, 25% nitroglycerin and 15% diethylene glycol dinitrate. The remaining species make up 1% of the mix. The notching of the propellant rods, which the US Army wanted in 1997, was abandoned in 1998. The manufacturer also states an improvement in shooting precision. Another advance was achieved in combination with the ammunition container, which makes the M829A3 insensitive ammunition according to STANAG 4439. This means that the cartridge can be transported relatively safely even in the event of enemy fire. The new type PA171 transport container consists of a steel cylinder with two blow-out panels made of a glass fiber reinforced ionomer based on polyethylene . With fast and slow cook off ( FCO / SCO ) and the impact of rifle ammunition ( bullet impact, BI ), the ammunition only burns down instead of exploding like the M829A2 / PA116. The impact of splinters ( fragment impact, FI ) only leads to deflagration , while the detonation of a neighboring projectile and the impact of a shaped charge lead to the explosion of the ammunition. Compared to the M829A2 / PA116, which detonates in all three cases, the effects could thus be somewhat reduced.

M829A4

With the beginning of the development of the XM1202 Mounted Combat System , three types of ammunition were postulated which should be fired by his XM360 120 mm smoothbore cannon: the Advanced Kinetic Energy (AKE) projectile, the Advanced Multi-Purpose (AMP) ammunition and the mid-range Ammunition (MRM) . While the Future Combat Systems program has now been discontinued, the types of ammunition are being further developed for series production. General Dynamics Ordnance and Tactical Systems and Alliant Techsystems applied for the contract to develop the AKE ammunition, later known as the M829E4, with Alliant Techsystems (ATK) being awarded the contract in July 2011. In October 2015 the new version was accepted by the US Army and has been in production since December 2015. The M829A4 is said to have increased capabilities to combat tanks with the latest reactive armor ; in many respects it is very similar to its predecessor. The biggest difference is the introduction of an "Ammunition Data Link" (ADL), which enables information to be sent from the M1 Abrams' fire control system to the ammunition.

Data table

The following table lists the accessible data for the M829 ammunition family, as specified, for example, by the manufacturer Alliant Techsystems (ATK). However, the data show great creativity: For example, ATK specifies a projectile and penetrator length of 780 mm for the M829A1, which is impossible because the projectile still contains a ballistic hood and the tail unit with the tracer set, and the penetrator is therefore smaller than that Must be a floor. The 10% increase in muzzle velocity of the M829A3 compared to the M829A2 is also not apparent from the data.

| M829 | M829A1 | M829A2 | M829A3 | M829E4 | |||

|---|---|---|---|---|---|---|---|

| Commissioning | 1984 | Late 80s | 1992 | 2003 | vstl. 2014 | ||

| cartridge | |||||||

| Cartridge weight | 18.66 kg | 20.90 kg | N / A | 22.30 kg | N / A | ||

| Cartridge length | 935 mm | 984 mm | 982 mm | N / A | |||

| Transport container | none | PA116 | PA171 (IM) | N / A | |||

| bullet | |||||||

| Projectile weight | 7.03 kg | 9.0 kg | 7.9 kg | 10.0 kg | N / A | ||

| Projectile length | 615 mm | 780 mm | 924 mm | N / A | |||

| Sabot | Aluminum, 4 parts | Alu, 3-part | CFRP, 4-part | CFRP, x-part | N / A | ||

| Penetrator weight | N / A | 4.6 kg | N / A | ||||

| Penetrator length | ~ 432 mm | ~ 684 mm | N / A | ||||

| Penetrator diameter | 24 mm | 22 mm | N / A | ||||

| Length / diameter ratio | ~ 18 | 31 | N / A | ||||

| Probable construction | Steel case with uranium-titanium alloy (99.25: 0.75) | possibly like M829 | Monoblock made of tungsten-uranium alloy (~ 1: 1) | possibly like M829A2 | N / A | ||

| Propellant | |||||||

| Propellant charge | JA2 perforated 19 times | RPD-380 | N / A | ||||

| Propellant charge lighter | M125 | M129 | M123A1 | N / A | |||

| Propellant weight | 8.1 kg | 7.9 kg | 8.7 kg | 8.1 kg | N / A | ||

| Chamber pressure | 5100 bar | 5600 bar | 5655 bar | N / A | |||

| Muzzle velocity | 1670 m / s | 1575 m / s | 1680 m / s | 1555 m / s | N / A | ||

Web links

- ATK - Conventional 120mm Tank Ammunition Manufacturer's website

- Globalsecurity: M829 120mm, APFSDS-T

Individual evidence

- ↑ a b Janes 120 mm M829 APFSDS-T cartridge (United States), Tank and anti-tank guns

- ↑ FAS: M865 TPCSDS-T 120mm Cartridge

- ↑ a b c Los Alamos Science - ARMOR anti-ARMOR materials by design (PDF file; 1.59 MB)

- ↑ International Journal of Impact Engineering; Volume 12, Issue 1, 1992, Pages 65-88: Axial and lateral impulsive loading of kinetic energy projectiles during launch DA Raberna, Los Alamos National Laboratory

- ^ Defense Technical Information Center Compilation Part Notice: Relative Erosivity of Nitramine Gun Propellants with Thermoplastic / Elastomer Binder Systems

- ↑ Jane's - 120 mm M829A1, M829A2 and M829A3 APFSDS-T cartridges (United States), Tank and anti-tank guns

- ↑ Dr. John Tierney; Scientist. Archived from the original ; accessed on March 25, 2018 : "He co-invented the Rapid Induction Lamination Process (RAIL) for facilitating the high speed production of the M829E3 sabot at ATK rocket center."

- ↑ AUMY RESEARCH LABORATORY - Rapid Automated Induction Lamination (RAIL) for High-Volume Production of Carbon / Thermoplastic Laminates (PDF file; 2.46 MB)

- ↑ US ARMY ARMAMENT RESEARCH, DEVELOPMENT AND ENGINEERING CENTER: ABLATIVE EROSION MODEL FOR THE M256 / M829E3 GUN SYSTEM

- ↑ Annual Industrial Capabilities Report to Congress, February 1999: “In 1997, the Army projected that the kerf propellant finishing, the composite sabot, and the DU penetrator all were critical to the 120mm program. <...> In 1998 designs for the M829E3 round changed and the Army reevaluated the issues. The Army now projects that: <…> Kerf propellant finishing will not be needed for the M829E3 program "

- ↑ ATK - Conventional 120mm Tank Ammunition

- ↑ MUNITIONS SAFETY INFORMATION ANALYSIS CENTER - Insensitive Munitions State of the Art ( Memento from January 12, 2014 in the Internet Archive ) (PDF; 1.2 MB)

- ↑ Defense Industry Daily - Next-Gen 120mm Tank Killer: ATK's M829E4 AKE

- ↑ http://www.dote.osd.mil/pub/reports/FY2015/pdf/army/2015m829a4.pdf accessed on March 4, 2016 (English)