Joint (construction)

In construction, a joint is a deliberate or tolerance-related gap or space between two sub-areas, components or materials. In addition to a structural purpose, it can also be used for design. The joint pattern is the arrangement and appearance of the joints on a certain surface, such as brickwork or tile floors. The joint pattern is influenced by the shape of the stones or tiles used, the joint material used, the joint color and the design of the joint. Joint cut refers to the ornamentation of a building with dummy joints cut into the plaster .

In order to prevent the ingress of water, joints are sealed with paste-like, sprayable sealants such as acrylic or silicone or with prefabricated profiles , joint tapes , joint plates or swelling tapes . See: Joint sealing

species

Connection joint

Connection joints inevitably arise when two different components meet and the gap that is formed cannot be filled , plastered or wallpapered . For much attention the connection joints in sanitary areas, such as the connection of shower tray ( shower tray ), bathtub or sink to wall and floor, typically referred to as silicone joints are performed. In most connection joints, only slight relative movements occur, so that sealants with low elasticity can also be used.

Construction joint

Construction joints are dividing lines within components. In concrete construction , for example, they arise as offset joints between successive concreting sections. Concreting in several sections is often unavoidable due to the construction process. The aim is to create the best possible bond between the adjacent concreting sections. Since the reinforcement runs through the construction joints, traditional shuttering of the concreting section with wood would be complex. Today, expanded metal is mostly used for this , which is easy to cut and bend and ensures a certain interlocking of the concreting sections. If, for example, a straight joint course is desired for aesthetic reasons, formwork panels can be used in combination with a rebend connection for the reinforcing bars, which allow subsequent interlocking by bending the reinforcing bars when the concreting process is continued. In engineering structures such as bridge construction , screw connections are used because of the greater loads, with which the reinforcing steel is connected via construction joints. Tight construction joints are particularly important in structures such as the white tub . Injection or swelling joint sealing tapes are used to seal construction joints against groundwater . When building basements of finished parts (as solid wall or so-called double-wall Keller), the use of outer, strip-shaped face seals has proven made of plastic, which are glued waterproofed with the ground (see also chamfer ).

Structural joint

A building joint or building separation joint is a joint that is created when buildings, building wings or later construction sections are erected directly, but without interlocking, next to the neighboring component. It runs continuously between the two neighboring structures, but not necessarily through the foundations. Structural joints between new buildings ( e.g. terraced houses ) are designed as building separation joints by filling a continuous gap several centimeters wide with non-combustible, elastic material such as mineral wool in order to absorb any settlement that may occur, to reduce sound transmission and to avoid the entry of cold outside air.

Movement joint

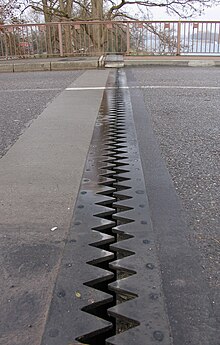

A movement joint , expansion joint , expansion joint or expansion joint is a joint for interrupting components , to stress cracks prevent. These cracks are caused by different movements of the adjacent surfaces due to thermal expansion , expansion due to moisture absorption or load- related changes in position and length (so-called creep). See also dilation for the formation of possible stress cracks . The joint avoids the resulting forces ( constraints ) as well as uncontrolled cracks within components or at connection points.

- Areas of application

- Bridges : Formation of transition structures to avoid constrained stresses , especially due to thermal expansion

- Parquet or laminate floors : Avoid tension, especially as a result of swelling and shrinking when the moisture content changes (mostly due to humidity , but also condensation ). This prevents the wood or laminate from pressing against adjacent components, from warping up or from developing gaping drying cracks.

- Floors in general, as well as coverings such as floor tiles : The connection joint between the screed and the floor covering to the wall is generally designed as an expansion joint.

- Brickwork is usually split by expansion joints in regular fields to avoid cracking due to the heating of the stiff masonry shell (traditional brickwork is not as vulnerable since both bricks and the mortar were more elastic than clinker and today facing bricks and the massive masonry wall also less heated than a thin wall shell that is simply blinded)

- At the Weißensee (Carinthia) , ice master Norbert Jank cuts a typically 5–10 cm wide joint into the natural ice at the lake towards the end of the season in order to create room for the expected expansion due to the upcoming sunshine and daytime warming and thus roof or valley-like breaks to avoid.

Varicose vein

Field stone buildings with strong, roof-like protruding joints are quite aptly referred to by experts as varicose vein joints.

Masonry joint

In masonry construction , a distinction is made between butt joints and horizontal joints : the vertical butt joints are between the heads of the stones within a layer of the wall; the horizontal bed joints lie between the stone layers.

Space joint

Space joints are used in concrete ceilings in road construction . Space joints separate the concrete slabs in their entire thickness. A wide, pre-formed joint gap allows the panels to expand and prevents the uncontrolled development of stress cracks.

Shadow gap

A shadow joint is an indicated, recessed joint between components, for example between a side wall and a suspended wooden ceiling or between the frame of a door that is flush with the wall and the adjacent wall surface. It is not necessarily an actual parting line. When constructing picture frames, the shadow gap serves to separate the picture and the frame.

Control crack joint and dummy joint

Control crack joints are specifically created so that unavoidable cracks in screed and reinforced concrete are not random and irregular, but straight and occur where they can best be checked. Concrete cracks must generally not be wider than 0.2 mm. If the surface is to remain airtight or watertight even when it is cracked, which is particularly important with a white tub , sealing profiles are inserted into the predetermined breaking points.

In screed as well as in road construction , predetermined breaking points are often made in the form of a simple trowel cut in order to weaken the cross-section of a component. When shrinking during the hardening process (setting), due to the effects of weather or wear and tear, a crack is created at this point in a controlled manner. Dummy joints do not completely cut through the component, but are notches made on the surface that are cut or notched in the desired places one or two days after the concrete or screed has been poured. Alternatively, inserts can be placed in the desired places while the concrete is being poured.

Like shadow gaps, dummy gaps are also used as a design tool, for example by inserting trapezoidal or triangular strips into the concrete formwork.

Light gap

A light gap is a gap between two components that appears as a light strip .

Shrinkage joint

A shrinkage joint is a joint that is left open between concrete components when concreting. Only after the shrinkage process is largely complete is the joint filled. Since this approach hinders the construction process , it is rarely carried out.

Press joint

Press joints are used in concrete pavements in road construction. They cut through the concrete slabs in their entire thickness. However, there is no joint gap between the individual panels so that the panels cannot expand.

Maintenance joint

The maintenance joint is a joint filled with sealant that is subject to rapid wear and tear due to chemical, biological, mechanical or weather influences. Maintenance joints must therefore be regularly subjected to a visual inspection or a leak test and, if necessary, replaced. The DIN 52460 (Sealing and glazing, terms) only includes definitions and says nothing to guarantee.

See also

literature

- Hansjörg Frey: Structural engineering - construction expertise . Europa-Lehrmittel, Haan-Gruiten 2003, ISBN 3-8085-4460-0 , p. 516 and 517 .

- Manfred Pröbster: Building sealants, successfully sealing joints . 2nd Edition. Vieweg + Teubner, Wiesbaden 2011, ISBN 978-3-8348-0952-0 .

- Eberhard Baust, W. Fuchs: Practical handbook sealants. 5th edition. HS Public Relations Verlag, Düsseldorf 2004, OCLC 314653349 .

- Friedrich Kobler: Fugue (architecture). In: Real Lexicon on German Art History . Volume X, 2014, Col. 1133-1169 ( rdklabor.de ).

Web links

Individual evidence

- ↑ Kristina Pfoser, Ernst Weber: Ambience - of the art of traveling: explorations on the frozen Weissensee. orf.at, Ö1-Radio, March 4, 2018, 10.05–10.20 a.m., (here: 10.18), audible 7 days at oe1.orf.at

- ^ Alfred Becker, Harald S. Müller: Concrete structures in the underground - infrastructure for the future. Universitätsverlag Karlsruhe, 2008, ISBN 978-3-86644-214-6 ( online ; PDF; 17 MB).