Roots blower

Roots blowers are positive displacement blowers without internal compression that are similar to gear pumps and rotary vane pumps . Two mostly three-wing runners transport a gas (mostly air) from the suction to the pressure side in the gaps between the wings and the outer wall , which is then compressed by the return flow of the compressed gas. Roots blowers are used for small to medium outputs and mostly small pressure differences (approx. 1 bar). They are used as simple vacuum pumps in industrial drying and extraction systems, when loading and unloading bulk goods such as grain on ships, as suction pumps in sewage tankers or as charging or flushing fans for combustion engines . There they are either driven by the crankshaft or, in the case of large diesel engines, electrically.

The name comes from the American brothers Philander Higley and Francis Marion Roots, who patented the blower in 1860.

Construction

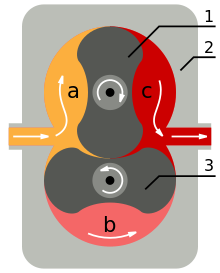

Roots blowers consist of a housing , two in the shafts rotate, the outside of the housing with a gear stage to synchronously are connected in opposite directions of the same speed. Each shaft has a rotor with a generally “8” -shaped profile (there are now other profiles). The tip of the head of the other eight runs in the gap of one eight; the two profiles "comb" with each other. They have to seal against each other and to the housing, but must not touch, since friction against each other would lead to seizure .

production

The early Roots wind and weather blowers were made of wood, with a rotor diameter of about two meters. Today's Roots housings and rotors are demanding components that are manufactured with high requirements in terms of dimensional tolerances , material quality and machining processes and are therefore expensive to manufacture.

Despite today's twisted, three- and four-bladed rotors, the Roots blower must not be confused with compressors such as screw compressors or scroll compressors that work with internal compression. Rotary piston machines with internal compression are even more expensive to manufacture, so that a market niche remains for the simple Roots blowers.

The thermal expansion of the components requires play in cold running, which deteriorates the seal as long as the machine has not yet reached its operating temperature. If the temperature is too high , the runners can jam or seize for the same reason .

The rotary lobes must not have any imbalance ; For use in mechanical engineering, the blower is usually tested on a test bench with 15 to 20% overspeed .

commitment

Blowers and ventilation systems

Roots blowers were first used in industry, mostly as wind generators for blast furnaces . Due to their design, Roots blowers are well able to suppress pressure surges and even the spread of flames from one side to the other. Therefore, they are ideal for ventilation systems in hazardous areas, such as a silo and Entladegebläse for bulk materials or for ventilation of mines and bunkers .

Flushing fan for two-stroke diesel engines

Two-stroke diesel engines (such as the Commer TS 3 or the engine of the Krupp Titan and engines from Cummins and Detroit Diesel ) almost always had Roots blowers for flushing. In the most efficient heat engines of all, the two-stroke marine diesel drives , Roots fans are often found as auxiliary and start-up fans. Instead of being driven by the crank mechanism in a fixed speed ratio, they can also have their own speed-decoupled drive.

Charging for racing vehicles

Paul Daimler was the first to install a Roots charger in a car in 1921. The emergence of the Roots loader in racing in the mid-1920s ( Blower Bentley versus Mercedes SSK ) was the trigger for the racing formula discussions: as far as displacement is a racing class criterion, since then a correction factor has often been added to the displacement of a turbocharged engine in order to not to give it a competitive advantage over uncharged engines. This means that a turbocharged engine must have a smaller displacement than the naturally aspirated engine. This often applies regardless of the principle of the charger, whether turbo or compressor.

In addition to the supercharged racing cars of the 1920s, particularly successful racing vehicles were the Auto Union Grand Prix cars between 1934 and 1939. The 500 cc BMW racing motorcycles of the 1930s also achieved numerous racing victories with Roots loaders. In 1939 "Schorsch" Meier was the first foreigner to win the senior race at the famous Tourist Trophy on the Isle of Man .

Compared to other motor loaders

If the blower is used as a charger, it runs dry; As a Roots compressor for higher pressures from 8 bar, it is oil-lubricated so that it achieves its sealing effect. However, the efficiency decreases sharply with increasing pressure ratio, so that compressors with internal compression (screw and scroll compressors) and exhaust gas turbochargers are more efficient as supercharging fans in internal combustion engines.

Mechanically driven supercharger respond more quickly to rapid load increase (sudden acceleration) as the high-revving exhaust gas turbocharger with a typical " turbo lag ": advantage of the piston supercharger is available even at low speeds, boost pressure, while about turbo compressor to build pressure appreciably usually only at higher speeds. Sometimes engines have a Roots blower for low speeds and an exhaust gas turbocharger for high speeds, between which a switch is made. The fan drive wheel can be equipped with a magnetic coupling (as with the air conditioning compressor ), with which it can be decoupled when the load is low.

Classification and functioning

Roots blowers belong to the group of twin-shaft rotary displacement machines in rotary piston design. They work according to the principle of external compression (also known as full pressure compression) so that the working medium does not experience compression due to a change in volume in the closed working chamber, but is pushed out against the system counter pressure. The resulting backflows from the pressure side into the opening working chamber at the beginning of the extension are on the one hand unfavorable for the thermodynamic process and on the other hand cause the distinctive and especially loud noise at high speeds. ("Compressor screeching")

Alternative principles

For some time in the 1990s, VW built so-called G-superchargers with a fixed and an oscillating G-shaped component, which, like a compressor or the Roots charger, is mechanically driven. However, this G only has one continuous compression strip, which hardly generates any friction losses, but can fail in the event of lubrication errors. This construction principle has not proven itself in the long term and therefore disappeared again after a few years.

Among the mechanically driven charger systems there is also the so-called Comprex (or pressure cell) charger. As with the turbocharger, part of the energy contained in the exhaust gases is used here; the mechanical drive only has a control function.

See also

Web links

Individual evidence

- ↑ Archived copy ( memento of the original dated December 26, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.