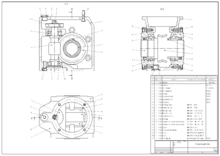

parts list

A BOM (English: parts list or bill of materials (BOM) ) is a structured arrangement of objects (e.g., from. Parts ) of a larger object, in particular of articles ( products ) or modules or a assembly . A parts list arranges the components of a product according to certain subject-specific criteria, whereby the technical function and geometry of the parts i. d. R. is secondary. The simplest arrangement is a continuous list of all required components of an assembly or a product. An assembly parts list is a listing of only the parts or assemblies of a 'higher-level' assembly that flow directly into this assembly. An assembly parts list arranges all parts and assemblies according to the assembly sequence. In the case of a spare parts parts list, only those interchangeable parts and assemblies that are required for the repair or must be replaced are listed.

BOM information is one of the most important data structures of a manufacturing company , because it documents which components a certain product consists of, which is particularly necessary for quality control and product liability . They are required in particular for production control and parts procurement so that the right parts are installed and the right material for the products to be manufactured can be purchased, stored and made available (see needs assessment , MRP II , ERP systems ). In process costing and other planning and control systems, parts lists are also used for the retrograde determination of actual consumption . A parts list can also be used to check the completeness of a product, a plant or an entire system supplied in individual parts.

BOM usage and BOM views

Parts lists can be differentiated according to their purpose or area of use , e.g. B. Development parts lists, production, procurement or spare parts lists. Such an application parts list then only contains the components and information that are required for the respective application; For example, only those components are stored in a spare parts list that can also be ordered as spare parts. If there is a separate parts list for each application in a company, this means that the product-related parts list data is saved multiple times and there are inconsistencies between the application parts lists. In the worst case, this can lead to technical problems or errors in the process, which can affect product safety (see Product Safety Act (Germany) ) and thus also product liability . In addition, this leads to time delays, increased administrative expenses and financial problems in the commercial process. That is why large companies and corporations in particular that manufacture complex products are working on integrated parts lists and continuous parts list processes that can be used jointly by all departments and users, despite different tasks and views.

At the center of an integrated parts list for various applications and users is a uniform product structure with common product-related data, which is supplemented by user-specific data. The common product-related data includes the part number, the part name, the unit of measure and the required number or quantity as well as the hierarchical order of the components. All users from the different departments of a company access this uniform product structure (production, procurement, logistics, sales, finance, ...), while the application-specific data can only be accessed by the respective departments. For reasons of security and clarity, the departments each have different access rights and an application-specific view of the parts list data .

Parts lists can be evaluated and sorted according to various criteria, depending on the product and / or application. This is particularly necessary for variant parts lists in order to only receive the information required for individual product variants.

Parts lists are required in particular for the deterministic determination of requirements , work planning and preparation and the creation of work instructions.

Delimitation and overlap

Parts lists differ from recipes in that they refer to discrete end products; they usually state which material is required to produce 1 piece of the end product (for example 1 telephone). Recipes, on the other hand, usually relate to a certain amount of the end product (for example 1 kg of cake). In foundries one speaks of category lists , which refer to the material composition for a melt. In the wood processing industry one speaks of wood lists , of material lists in the construction industry.

The term BOM ( bill of materials ) is also increasingly used in German . However, the closer translation for parts list is parts list . BOM generally refers to lists describing materials, so it can also mean a purchase requisition , for example .

In contrast to the parts list, which is based on finished parts, a work plan describes the production process in relation to the individual work steps and process sections for completing the part with the corresponding standard times (set-up time, execution time, etc.). Bills of material and work plans can be linked with one another by assigning them accordingly. A parts list position is assigned to a specific routing position; In the case of part variants that are installed at the same time, several parts list items can be assigned to one work plan item.

Proof of use

A parts list breaks down a product analytically ('from top to bottom') into its components; It begins with the top level, the product itself, and ends at the bottom level with the individual parts, raw parts, materials, liquids, etc. The reversal of this view is referred to as a proof of use , which is why there is always a corresponding proof of use with every parts list which the product can be synthesized from the respective components ('from bottom to top').

Parts list structure or parts list types

In the literature, a distinction is usually made between the basic types of the quantity overview parts list, the structural parts list, the modular parts list, the variant parts list and the complex parts list. The distinction mainly relates to the specific representation on the screen or in a printout. EDP systems usually save parts list information in the form of the modular parts list, since all other required types can be generated from this by vertical parts list resolution and the maintenance effort is lowest. In the case of complex products that are manufactured in flow production (e.g. automotive industry), the structural parts list is often found, from which modular parts lists and where-used lists can be generated.

If you look at a specific product structure in the form of a tree structure:

| P | |||||||||||||||||||||||||

| E1 (1x) | B (1x) | ||||||||||||||||||||||||

| E1 (1x) | E2 (1x) | E3 (2x) | |||||||||||||||||||||||

with P: product, B: assembly, E1, E2 and E3 individual parts, the individual forms of representation are as follows:

Quantity overview BOM

The quantity synopsis parts list (English: “quantity synopsis parts list”) lists the quantities required for the product in an undifferentiated manner as an exploded parts list (the listing of assemblies in the quantity overview parts list is not recommended). Example of the parts list for product P:

| Part no. | designation | number |

|---|---|---|

| 14329 | B. | 1 |

| 14245 | E1 | 2 |

| 14246 | E2 | 1 |

| 14248 | E3 | 2 |

By multiplying the required quantities by the quantity of the product to be manufactured, the so-called order parts list results.

Structure BOM

A structural parts list (English: "structural parts list" or "indented BOM") contains all assemblies, individual parts and raw materials of a product and shows the composition of a product across all production stages in tabular form. Its information content corresponds to the product structure. The quantities given refer, depending on the agreement, to the entire product or to a unit of quantity of the higher-level part, explained using the example of product P:

| Part no. | step 1 | Level 2 | number |

|---|---|---|---|

| 14245 | E1 | 1 | |

| 14329 | B. | 1 | |

| 14245 | E1 | 1 | |

| 14246 | E2 | 1 | |

| 14248 | E3 | 2 |

Assembly parts list

Modular parts lists ("unit list" or 'single-level BOM') are characterized by the fact that only one level of the product structure is considered: assemblies receive their own parts lists, which are used in the parts lists of the higher-level groups, again explained using the example for product P:

Product P

| Part no. | designation | number |

|---|---|---|

| 14245 | E1 | 1 |

| 14329 | B. | 1 |

Assembly B

| Part no. | designation | number |

|---|---|---|

| 14245 | E1 | 1 |

| 14246 | E2 | 1 |

| 14248 | E3 | 2 |

Variant parts list

In a variant parts list ("variant parts list" or "modular BOM"), according to DIN 199-1: 2002-03, several parts lists are summarized on one form in order to be able to list different items with a mostly high proportion of identical components (→ Variant (product) ). In an electronic parts list system, the different product variants are saved together with the different variants of the parts and assemblies. Each product variant is distinguished by one or more attributes; these respectively applicable attributes are then saved with the corresponding part and assembly variants so that a correct assignment to the product variant (s) is possible. There are different types of variant parts lists, e.g. B .:

- Basic version and plus / minus parts list

- Identical and variant parts parts list

- Complex parts list

Complex parts list

The complex parts list (eng. 'Configurable BOM' or 'Super-BOM'), which is also called 'selection parts list', 'maximum parts list' or 'configurable parts list', is a form of variant parts list in which all variants of a product or an assembly can be mapped together. In order to distinguish the variants from one another and to be able to assign the parts and assemblies to a single, specific product variant, these must be provided with product-related attributes . These attributes are characteristics that describe the product more precisely. A particularly effective type of attribution is the specification of an algebraic expression that relates to a set or subset of the product variants. This presupposes an algebraic product definition (product encryption) with the help of characteristics. Depending on which product it is, features can relate to the equipment, functions, colors, materials or geometric, physical or chemical properties of a product. The characteristics can either only have a loose relationship with one another or form a structure in the form of an algebraic association . This type of product definition is mainly found in industries that manufacture complex and varied products. In the automotive industry, for example, vehicles are described by a large number of features (equipment) that can be selected with the help of product configurators . Accordingly, many vehicle manufacturers use complex algebraic parts lists. Depending on the specific form of the product definition, these then differ in the type of attribution (→ variant management ).

MRP BOM

The MRP BOM provides information about the MRP sequence. The parts are grouped together for lowest use and can be planned at the same time. It is possible to transfer structural and disposition parts lists.

Multiple parts list

If the composition of a material can change depending on the lot size, i. H. From a certain lot size, the quantities of one or more materials change or new components are added, then this material BOM is converted into a multiple BOM. Alternatives to the original parts list are created. These are also known as variant parts lists.

Transfer of parts list structures

A structural parts list or a gozintograph can be generated from a modular parts list. Likewise, modular parts lists can in turn be generated from a structural parts list; in the latter case, however, it is not always ensured that the generated construction kit parts lists are unique if the construction kits occur in different places in the product. Such transfers are not possible with the quantity BOM because intermediate structures such as assemblies are hidden there. The quantity list, on the other hand, can easily be converted into a corresponding list of where-used parts , which is often sufficient for simple material requirements planning.

literature

- DIN 199 : Terminology in technical product documentation

- DIN 6771-2 parts lists withdrawn: 2007-10

- ISO 7573 (2008-11): Technical product documentation - Parts lists.

- Bruno Grupp: Electronic parts list organization in practice. Forkel Verlag, Stuttgart 1976, ISBN 3-7719-6130-0 .

- W. Herlyn: On the problem of mapping products with many variants in the automotive industry. VDI-Verlag, Düsseldorf 1990, ISBN 3-18-145216-5 .

- O. Rosenberg: Variant production. In: W. Kern among others: Concise dictionary of the production economy. Schäffer-Poeschel Verlag, Stuttgart 1998, ISBN 3-7910-8044-X , Sp. 2119-2129.

Web links

- Parts list definition In: Gabler Wirtschaftslexikon

- C. Fresh; A. Marbach; F. Tichla; F. Mantwill: "Consistent variant control using the rule-based complex parts list" [1] ;

See also

Individual evidence

- ↑ M. Eigner: Model-based virtual product development. Springer Verlag, Berlin 2014, p. 243.

- ↑ [VDI T 77]: Electronic data processing in production planning and control (VI). Conceptual contexts. Definitions of terms. VDI Verlag, Düsseldorf 1976, p. 117 ff.

- ↑ W. Herlyn: On the problem of mapping products with many variants in the automotive industry . VDI Verlag, Düsseldorf 1990, ISBN 3-18-145216-5 .

- ↑ W. Herlyn: PPS in automobile construction - production program planning and control of vehicles and assemblies . Hanser Verlag, Munich 2012, ISBN 978-3-446-41370-2 .