Profile steel

Profile steel refers to semi-finished metal products (" long products ") made of steel as well as individual rod-shaped components ("steel girders") from this product group. Profile steel is rolled, drawn or pressed steel in a defined shape, the cross-section of which is the same over its entire length.

Steel profile is a name for both the component itself and its respective cross-section, the profile . A steel profile can be assembled and connected by welding , screwing or riveting . Standardized cross-sections are often produced by hot rolling , whereby they are given a rolling skin . Products without mill skin are also known as bright steel .

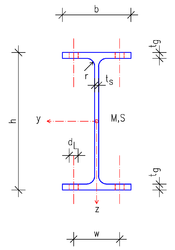

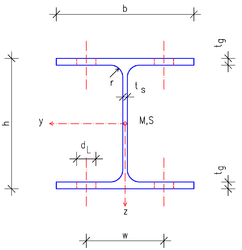

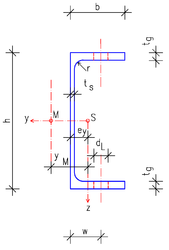

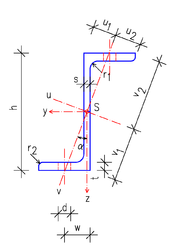

In the case of three-legged steel profiles, the outer legs are called a flange or belt . The connecting middle part is called the bridge .

In contrast to solid wall girders, hollow box girders and hollow profiles enclose a cavity and, in addition to two flanges, can also have two or more belts and are usually not counted as steel profiles, but as pipes or sheet metal girders, as further steps are required in addition to rolling.

Common profiles

- I-profile (double T-beam) according to DIN 1025

- Narrow I-profile with inclined inner surfaces of the flanges (INP) according to DIN 1025-1

- Medium I-profile with parallel inner surfaces of the flanges ( IPE series) according to DIN 1025-5

-

Wide flange beam

- Light design (IPBl or HEA series) according to DIN 1025-3

- Standard design (IPB or HEB series) according to DIN 1025-2 (EN 10034)

- Reinforced design (IPBv or HEM series) according to DIN 1025-4

- GI profile (pit support I profile, DIN 21530), I profile reinforced on the flange and transition

- P-profile with parallel inner surfaces of the flanges, formerly also called "Peiner" or Peiner support (PDF file) [1]

- U-profile with inclined inner surfaces of the flanges ( UNP series) according to DIN 1026-1

- U-profile with parallel inner surfaces of the flanges (UPE series or UAP series) according to DIN 1026-2

- T-profile isosceles with rounded edges and transitions according to DIN EN 10055 (old according to DIN 1024)

- Z-profile round-edged according to DIN 1027

- L-profile (also angle iron , angle profile or angle beam) according to DIN EN 10056-1

- equal length flanges, isosceles (old according to DIN 1028)

- flanges of different lengths, unequal legs (old according to DIN 1029)

- TH profile (Toussaint-Heintzmann profile for pit lining )

- Holland profile

- Round and square tube

-

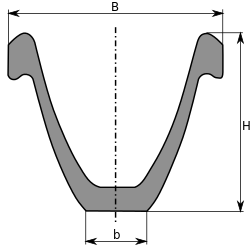

Retaining wall

- heavy sheet pile wall (double-T)

- lightweight sheet pile wall (Larssen profile, Z profile)

What all these profiles have in common is that not only the shape is precisely specified for them in the standard, but also other cross-sectional values for the static strength and deformation calculation :

- Circumference in cm

- Area of the cross-section in cm²

- Weight in kg / m

- Position of the two main axes of gravity and the center of gravity of the cross-section

- Static moment around the two main axes of gravity in cm³

- Moment of resistance in cm³

- Axial area moment of inertia in cm 4

- Surface centrifugal moment for point-symmetrical cross - sections in cm 4

- Polar section modulus in cm³

- Polar area moment of inertia in cm 4

- Position of the center of shear for asymmetrical cross-sections in cm

- Warping moment of resistance in cm 6

The names of these quantities come from the physics of rotating bodies, only here instead of the mass, an area is decisive. In analogy, the unit for the area moment of inertia cm² × cm² = cm 4 (area × distance²) applies to the mass moment of inertia and its unit of measurement kg × cm² .

The area inertia and area centrifugal moments can be converted to other than the main axes of gravity of the cross-section with the help of the tensor calculation . Since the formulas required for this are cumbersome and error-prone, one also uses a drawing aid, the Mohr's circle of inertia .

literature

- Ulf Hestermann, Ludwig Rongen: Frick / Knöll Bau Konstruktionslehre 1 36th edition, Springer Verlag Fachmedien, Wiesbaden 2015, ISBN 978-3-8348-2564-3 , pp. 381–384.

- Heinz M. Hiersig (Ed.): VDI-Lexikon Maschinenbau. VDI-Verlag GmbH, Düsseldorf 1995, ISBN 978-3-540-62133-1 .

- Peter Kiehl (Ed.): Introduction to the DIN standards. 13th edition, Beuth Verlag, Berlin 2001, ISBN 3-519-26301-7 .