Stiffness

The stiffness is a quantity in engineering mechanics . It describes the resistance of a body to elastic deformation caused by a force or a moment ( bending moment or torsion moment , depending on the load ). Accordingly, there are different types of stiffness: elongation, shear, bending and torsional stiffness .

The rigidity of a component depends not only on the elastic properties of the material (the modulus of elasticity ), but also crucially on the geometry of the component.

The stiffness applies in the linear-elastic range , i.e. only for small deformations where these are still proportional to the forces acting.

The stiffness is not to be confused with the strength . This is a measure of the limit load ( elasticity limit ) of a material, i.e. the stress at which the elastic deformation changes into a plastic deformation or at which the material breaks.

For slender bodies with a uniform cross-sectional area (in size and shape) over the length, stiffness can also mean the relative stiffness related to the length . The reciprocal of stiffness is called compliance .

For more complicated geometries, it is often not possible to separate the stiffnesses according to the type of load. A load on train can also lead to twisting , e.g. B. in a helix . The (absolute) stiffness is then a tensor .

Relative stiffness

Tensile stiffness

The tensile stiffness is the product of the modulus of elasticity of the material in the direction of loading and the cross-sectional area perpendicular to the direction of loading (regardless of the shape of the cross-section):

- for example in

This formulation applies to free transverse contraction of the cross section; In the case of handicapped transverse contraction, the transverse contraction handicapped module is used instead of the modulus of elasticity.

The longitudinal expansion of the body is proportional to the acting normal force and inversely proportional to the elongation stiffness in the longitudinal direction (longitudinal stiffness):

with the normal stress

The extent to which the absolute change in length of a component subject to bending stress is at a given load (tensile force) depends not only on the tensile strength but also on its length, s. u. absolute stiffness.

Shear stiffness

The shear stiffness is the product of the shear modulus of the material and the cross-sectional area :

- for example in

The cross- section-dependent correction factor takes into account the non-uniform distribution of the shear stress over the cross-section . Often the shear stiffness is also expressed using the shear area .

The shear distortion of the body is proportional to the applied shear force and inversely proportional to the shear stiffness:

Bending stiffness

The bending stiffness is the product of the elasticity module of the material and the area moment of inertia of the cross-section (which in turn depends largely on the shape of the cross-section):

- for example in

The curvature of the body is proportional to the applied bending moment and inversely proportional to the bending stiffness:

How strong the absolute deflection or lowering of a bending-stressed component is at a given load (bending moment) depends not only on the bending stiffness but also on its length and the storage conditions .

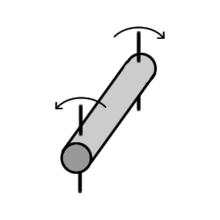

Torsional stiffness

The torsional stiffness (also called torsional stiffness) is the product of the shear modulus of the material and the torsional moment of inertia :

- for example in

The torsional moment of inertia is related to the axis around which the body is twisted. It is often erroneously claimed that it corresponds to the polar area moment of inertia of a cross-section. In reality, however, this only applies to circular and closed circular ring cross-sections. Otherwise, a closed formula can only be specified for the torsional moment of inertia in special cases.

The twisting or twisting of the body (twist per unit length) is proportional to the applied torsional moment and inversely proportional to the torsional rigidity:

The absolute angle by which a body is twisted under a certain load depends not only on the torsional moment of inertia but also on its length and the storage conditions.

Spring constant

In practice, it is often not the elongation but the absolute change in length relative to the force that is of interest. Therefore, the spring constant for springs is described by the ratio of the force required for a specific deflection :

For a uniform cross-section, the spring constant is equal to the stiffness of the spring cross-section divided by the length of the spring:

It follows that the spring constant halves when the length of the spring is doubled.

For example, a pull rod to the cross section A = 100 mm 2 and a modulus of elasticity of 210,000 N / mm 2 has a (stretching) of rigidity E · A = 2.1 × 10 7 N. If the rod L = 100 mm long, its spring constant E · A / L = 210,000 N / mm.

See also

literature

- Norbert Herrlich, Johannes Kunz: Plastic Practice. Construction, Volume 1 / Part 5 / Chap. 8.2: Design suitable for use, rigidity . WEKA Media, Augsburg 1999, ISBN 3-8111-5935-6 (March 1999, loose-leaf edition in 2 folders + 1 CD-ROM; Google Books )

- Dietmar Gross, Werner Hauger, Jörg Schröder, Wolfgang A. Wall: Technische Mechanik, Volume 2: Elastostatik , Springer Verlag, 10th, revised edition, 2009, ISBN 978-3-642-00565-7

- Karl-Eugen Kurrer : History of Structural Analysis. In Search of Balance , Ernst and Son, Berlin 2016, p. 102f, ISBN 978-3-433-03134-6 .