Plasticity (physics)

The plasticity or plastic deformation (in arts and crafts and plasticity ) describes the ability of solids , under a force after exceeding a yield point irreversibly to deform (flow) and maintain this form after exposure. No deformations or only elastic deformations occur below the yield point. In practice, however, these effects always occur together.

In contrast, an elastic material would resume its original shape and a brittle material would react with immediate failure - one speaks of brittle fracture . B. occurs in ceramics and body-centered cubic metals at low temperatures .

If a substance flows immediately under the action of force, and not only after a flow limit has been exceeded, then it is not a solid , but a viscous liquid .

Within the material, plastic deformation is a result of shear stresses between the molecules. With regard to the technical properties of a material, plasticity can be divided into, depending on the force applied

- Ductility ( English ductility. ): The plastic behavior under tensile stress (Tension)

- Malleability ( English malleability. ): The plastic behavior under compressive stress (compression).

Ductility is also used synonymously with plasticity, which means that these terms cannot always be clearly differentiated from one another.

Material behavior and its description

An ideally plastic body behaves like a rigid, non-deformable solid as long as the applied stress remains below the yield point . When it reaches the value , it begins to deform irreversibly and indefinitely.

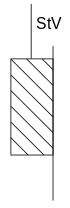

This behavior can be modeled by a St. Venant element, a friction block that only starts moving after a certain static friction force has been exceeded .

In nature, however, ideally plastic behavior practically does not occur, but always together with elastic or viscous effects. For example, steel behaves elastoplastically in tensile tests. In contrast, the Bingham fluids show a viscoplastic behavior. They behave like a solid below a flow limit and like a liquid above it.

A model for the mathematical description of plasticity comes from Eugene C. Bingham . This is mainly used for finite element calculations of the viscoplasticity of materials such as raw brick. In continuum mechanics , plasticity theory deals with the irreversible transformation of matter.

causes

The plastic deformation behavior depends, among other things, on the state of stress, the temperature, the type of load and the speed of loading. In addition to conventional plasticity, high-temperature plasticity , creep deformation and superplasticity are also known .

The plastic deformation of crystalline solids (metals) is described microscopically using the dislocation theory. A lower shear force is required to cause plastic deformation by moving individual defects ( dislocations ) through the solid than to move all rows of atoms at the same time. A large carpet that should only be moved a little is often used as an analogy . This can be done very effortlessly by driving a small crease through the carpet instead of moving the entire carpet at once. (See also strength )

Technical importance

The plasticity determines the ductility and formability of a material.

Examples

High plasticity:

- Dough

- moist clay

- Metals and metal alloys with a suitable atomic lattice:

- red-hot steel while forging

- Cold forming of sheets during driving

- a thin metal wire can be bent into any shape

- Typical Bingham fluids such as toothpaste , mayonnaise or butter can be softened and made to flow with just a little pressure on the tube or with a knife.

- At very high pressure , ice becomes plastic and can flow as a glacier .

- At even higher pressures, halite (rock salt) also becomes plastic and can form salt domes and even salt glaciers .

Low plasticity:

- A rubber band is very elastic and therefore returns to its original shape when the load is released.

- Ceramics usually break brittle without plastic deformation.

literature

- EC Bingham , Fluidity and Plasticity. McGraw-Hill , New York 1922

- AH Cottrell , Dislocations and Plastic Flow in Crystals. Clarendon Press , 1953

- WF Hosford, The mechanics of crystals and textured polycrystals. Oxford University Press , 1993

- Gustav ER Schulze , metal physics - a textbook . Akademie-Verlag , Berlin 1967

Individual evidence

- ↑ DIN 1342-1: Viscosity - Part 1: Rheological terms (2003-11).

- ^ Jack C. Rich: The Materials and Methods of Sculpture . Courier Dover Publications, 1988, ISBN 0-486-25742-8 , p. 129.

- ^ EC Bingham, Fluidity and Plasticity. New York, McGrew-Hill, 1922.