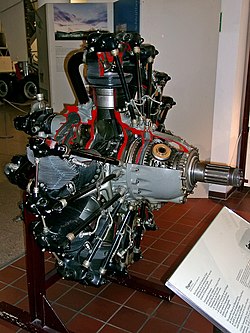

BMW 132

| BMW | |

|---|---|

|

Cutaway model BMW 132 |

|

| 132 | |

| Production period: | 1933-1945 |

| Manufacturer: | BMW |

| Working principle: | Otto |

| Motor design: | S9 |

| Valve control: | OHV |

| Displacement: | 27689 cm 3 |

| Mixture preparation: | Carburetor or direct injection |

| Engine charging: | Skid loader |

| Power: | 404-526 kW |

| Dimensions: | 430-525 kg |

| Previous model: | none |

| Successor: | none |

The BMW 132 is an air-cooled aircraft engine from the German manufacturer BMW . Of the nine-cylinder radial engine with spark ignition , over 21,000 pieces were built in various variants between 1933 and 1945.

history

The BMW 132 is a further development of the Pratt & Whitney R-1690 , also known as the Pratt & Whitney Hornet A , for which BMW had the reproduction rights from January 3, 1928. The engines manufactured afterwards were called BMW Hornet. In 1933, the company acquired another production license from Pratt & Whitney , which is now valid for all of Central Europe, this time for the improved Hornet B. At the same time, however, BMW was already developing its own engines, such as the BMW 128, and began developing the BMW 132, with recycling the experience in manufacturing and using the BMW Hornet. It was essentially a Hornet redesigned and improved on the metric system and had almost identical cylinder dimensions. This meant that the BMW 132 and the R-1690 could largely be interchanged. This made it possible to equip German aircraft with either of the two for export.

There were a variety of designs, with a Pallas- Stromberg or Mona-Hobson carburettor , as a floor (A, D, E, L) but also as an altitude motor (D). From 1937 onwards, there were also versions with direct fuel injection , which were also fitted with floor (K, M) and altitude engine versions (F, J, N). The engine was continuously developed. Advances in the materials and their processing allowed the performance to increase steadily. From the 132 L version onwards, it was possible to use a better casting technique to produce significantly finer cooling fins in order to significantly enlarge the cooling surface. One inlet and one outlet valve per cylinder provided for the gas exchange, the outlet valves were filled with sodium for better heat dissipation .

Further developments with a new single-stage two-speed charger were given the designations P, Q, R, S, with P and Q or R and S only differing in the direction of rotation of the crankshaft. These last series achieved a short output of 880 kW (1136 hp). A new engine series of its own was to be derived from this, the BMW 136 , which, however, no longer came about due to the further increased performance requirements of military aviation. Another version, the BMW 134 , was supposed to do without so-called fuel savings during the war ; it remained with only one test engine. The BMW 139 double radial engine was constructed from components from the BMW 132 . Despite many attempts, it was not possible to solve the existing cooling problems of this engine. Its development was eventually stopped in favor of the BMW 801 .

Although the engine was planned for a number of fighter jets such as the Junkers Ju 86 (retrofitted to replace the unsuitable Jumo 205 diesel engine ), the Do 17 P and the Henschel Hs 123 , it soon proved itself for fighter jets than too weak. In the course of the Second World War, the BMW 132 was therefore replaced by more powerful engines. As a drive for the Ju 52 , however, it continued to be manufactured and thus helped the most successful German transport aircraft of the 1930s and 40s to gain its reputation.

use

The BMW 132 was built into a variety of well-known aircraft types, such as the Junkers Ju 52 and the Ju 86 as well as the Junkers W 34 hi . Together with the long-haul passenger aircraft Focke-Wulf Fw 200 , the engine gained international attention in 1938 after the successful non-stop flight from Germany to New York.

The engine was also used in the aircraft Dornier Do 17 P , Junkers Ju 46 , Junkers Ju 90 , Junkers Ju 160 , Arado Ar 95 , Arado Ar 195 , Arado Ar 196 , Arado Ar 197 , Heinkel He 114 , Heinkel He 115 , Henschel Hs 122 , Henschel Hs 123 , Henschel Hs 124 , Blohm & Voss BV 141 A, Dornier Do 18 L, Blohm & Voss Ha 137 A, Blohm & Voss Ha 140 , Blohm & Voss BV 142 and Focke-Wulf Fw 62 .

Constructive execution (BMW 132 F, J, K, M, N)

Motor housing

As in the original R-1690 model, the engine housing consists of five parts - the front part, the two-part crankcase, the two halves of which are connected by nine screws, the mixture charger housing and the equipment carrier. The front part of the housing with or without a reduction gear and the thrust ball bearing has mounting pins for the cam drum drive , which contains the two cam rings with four cams each and the back gear connected to the crankshaft with a ratio of i = 8. The rear crankcase half carries the loader housing on similar pins, to which the auxiliary equipment rack is flanged. Steel rings were inserted into the crankcase halves, which in turn held the ball bearings of the crankshaft . Both housing halves have their own oil return.

crankshaft

The single-cranked, triple-bearing crankshaft consists of two parts that are connected by a screw bolt. While the front part of the crankshaft carries the output shaft, a crank arm and the crank pin, the rear part consists of a crank arm and a mounting pin for the rear crankshaft bearing. Both crank webs carry two-part riveted counterweights. The axial forces are absorbed by the ball bearing in the front part of the housing. The rotation of the crankshaft is transmitted to the propeller either directly or via a planetary gear with reduction ratio i = 1.38 (on models 132 J, K) or 1.613 (on models 132 F, M, N).

Connecting rods and pistons

The main connecting rod, to which the eight secondary connecting rods are attached, runs on the crankshaft crank pin with a slide bearing made of a steel shell with lead bronze. The foot bearings of the connecting rods as well as the piston pins have bearings made of phosphor bronze. All connecting rods have a double-T cross-section to increase buckling strength . The flat-bottomed aluminum pistons are connected to the connecting rod by a hollow piston pin and have three compression rings above and an oil control ring below the piston pin eye.

Cylinder and cylinder head

The pistons run in tightly ribbed cylinders made of chrome-molybdenum steel, onto which the aluminum cylinder heads are shrunk. The valve guides of the intake and exhaust valves, which are inclined at 70 ° to each other, protrude from the cylinder head. Each valve is kept closed by two concentrically arranged valve springs and operated by the cam drum via tappets , push rods and rocker arms. The outlet side has significantly stronger ribbing than the inlet side, which is less thermally stressed. The valve seats are shrunk into the cylinder head. The holes for the two spark plugs of the double ignition are located on the front of the cylinder heads, while the injection valve on engines with direct injection is screwed in on the rear. The outlet valves were made of austenitic steel and were filled with sodium for better heat dissipation. Chrome steel was the material of the massive intake valves.

Mixture preparation and lubrication

In the case of engines with injection, the fuel is injected directly into the cylinders via the injection valves from a Bosch nine-piston injection pump, which was flanged to the equipment carrier. The amount of fuel was regulated depending on the air pressure in the supply line to the inlet valves and the temperature of the fresh gas. The engine was supplied with compressed fresh air by a centrifugal charger. The ratio of the supercharger drive for BMW was 132 K and M i = 0.142857. The corresponding values for the otherwise identical motors F were i = 0.087719, for versions J and N i = 0.098619. There were two Bosch magnets for the ignition. The firing order was 1–3–5–7–9–2–4–6–8. The cables to the spark plugs were shielded to avoid radio interference. The lubrication was ensured by a dry sump lubrication . The oil circulation was done by two pressure oil pumps, a main return pump and two auxiliary return pumps. The engine was started by a flywheel starter.

Technical specifications

| Bore (mm) |

Stroke (mm) |

Displacement (l) |

compression | Propeller gear (i) |

Length (mm) |

Transit diameter (mm) |

Weight (kg) |

Takeoff power (PS / min-1) |

Continuous output (PS / min-1) |

Full pressure height (m) |

Specific consumption (g / PSh) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 132 A | 155.5 | 162 | 27.7 | 6.0: 1 | without | 1270 | 1405 | 430 | 725/2050 | 550/1930 | 230 | |

| 132 Dc | 155.5 | 162 | 27.7 | 6.5: 1 | 1.613 | 1411 | 1380 | 525 | 850/2450 | 550/2100 | ||

| 132 F | 155.5 | 162 | 27.7 | 6.5: 1 | 1.613 | 1256 | 1372 | 525 | 800/2350 | 650/2200 | ||

| 132 J. | 155.5 | 162 | 27.7 | 6.5: 1 | 1.38 | 1256 | 1372 | 525 | 960/2550 | 715/2200 | ||

| 132 K | 155.5 | 162 | 27.7 | 6.5: 1 | 1.38 | 1256 | 1372 | 525 | 960/2550 | 715/2200 | 1800 | 215 |

| 132 M. | 155.5 | 162 | 27.7 | 6.5: 1 | 1.613 | 1256 | 1372 | 525 | 865/2450 | 670/2250 | ||

| 132 N. | 155.5 | 162 | 27.7 | 6.5: 1 | 1.613 | 525 | 865 | |||||

| 132 T | 155.5 | 162 | 27.7 | 730 |

literature

- Kyrill von Gersdorff, Helmut Schubert, Stefan Ebert: Aircraft engines and jet engines. Development history of German aviation engines from the beginnings to the international joint developments. Bernard & Graefe publishing house, Bonn 2007, ISBN 978-3-7637-6128-9 .

- Bill Gunston: Lexicon of the aircraft engines. Motorbuch Verlag, Stuttgart 1991, ISBN 3-613-01422-X .

- Jane's all the world's aircraft 1945. Harper Collins Publisher, ISBN 0-00-470831-8 .

- The BMW 132 Dc aircraft engine . Performance and reliability. In: BMW (ed.): BMW sheets . No. 33 . Munich November 1938, p. 15 ( bmw-grouparchiv.de [PDF; accessed on January 24, 2016] in-house communications from Bayerische Motoren Werke AG).

- Helmut Schneider: Airplane type book. 5th edition, Herm. Beyer Verlag, Leipzig 1944.

See also

Web links

- BMW 132. In: BMW History. BMW AG, accessed on January 24, 2016 (dossier of the BMW Group Archives).

- Description and operating instructions for the air-cooled aircraft engine BMW 132 A series 3 and E series 2. In: BMW history. BMW AG, 1938, accessed on January 24, 2016 (document from the BMW Group archive with images, 253 pages).