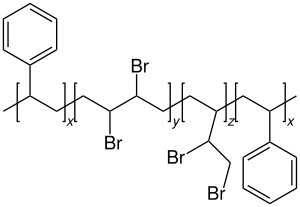

Brominated styrene-butadiene copolymer

| Structural formula | |||||||

|---|---|---|---|---|---|---|---|

|

|||||||

| General | |||||||

| Surname | Brominated styrene-butadiene copolymer | ||||||

| other names |

|

||||||

| CAS number | 1195978-93-8 | ||||||

| Monomers / partial structures | Styrene , butadiene | ||||||

| Qualitative molecular formula |

(C 8 H 8 ) x (C 4 H 6 Br 2 ) y (C 4 H 6 Br 2 ) z (C 8 H 8 ) x |

||||||

| Brief description |

transparent solid or white to beige powder |

||||||

| properties | |||||||

| Physical state |

firmly |

||||||

| density |

2.55-2.65 g cm -3 |

||||||

| Melting point |

> 250 ° C (decomposition) |

||||||

| solubility |

almost insoluble in water |

||||||

| safety instructions | |||||||

|

|||||||

| Toxicological data | |||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | |||||||

Brominated styrene-butadiene copolymer is a styrene-butadiene rubber , which has flame-retardant properties due to subsequent bromination of the remaining double bond on the butadiene . It is a polymeric flame retardant and is also known as PolyFR or pFR (FR from English flame retardant ).

It has good miscibility with polystyrene and allows the production of stable foams. It is used as a flame retardant in expanded ( EPS ) and extruded ( XPS ) polystyrene. This makes it an alternative to hexabromocyclododecane , which has been banned under the Stockholm Convention since 2015 .

history

The material was developed and patented by Dow . It is manufactured by licensees Chemtura , Albemarle Corporation and Israel Chemicals , who sell it under the names Emerald Innovation ™ 3000 , GreenCrest and FR-122P . Commercial types have a molar mass of around 100,000 grams.

proof

To prove which of the substances was used, extraction of EPS or XPS pieces in acetone and subsequent X-ray fluorescence spectroscopy can be used to distinguish between equipment with hexabromocyclododecane or PolyFR. Detection is also possible with nuclear magnetic resonance (NMR).

Environmental behavior

As a stable, almost water-insoluble polymer, brominated styrene-butadiene copolymer has no actual acute toxicity and is resistant to chemical-physical and biological degradation. According to a study published in 2019, pure brominated styrene-butadiene copolymer releases various, possibly environmentally relevant degradation products under intense UV radiation or long-term exposure to heat (60 ° C) for up to 36 weeks. This should be taken into account in all those countries in which the landfill of foam is permitted, although the results of another study from 2019 indicate that the acute toxicity of the degradation products to aquatic organisms is rather limited or does not occur at all. The industry association is critical of studies on pure brominated styrene-butadiene copolymer (with the addition of water) and the conclusions drawn from them with regard to the degradation behavior, since the flame retardant in foams is protected by the polystyrene matrix. That being said, they indicate that no significant acute effects were found in the studies mentioned.

literature

- US EPA : Flame Retardant Alternatives for Hexabromocyclododecane (HBCD) , 2014, 230 pp.

Individual evidence

- ↑ a b c d BASF: Third party submission of information on alternatives for Applications for Authorization , p. 3.

- ↑ a b c d e f g Safety data sheet for FR-122P Powder ( memento of April 18, 2015 in the Internet Archive ) at ICL Industrial, accessed on July 11, 2014.

- ↑ P. Rantuch, J. Martinka: The Appropriate Fire Retardant for Application in Expanded Polystyrene ,, 2013.

- ↑ a b INEOS Styrenics: Analysis of Alternatives - HBCDD Use in EPS for Building Applications , p. 8.

- ↑ BASF: First Styrodur plant completely switched to new flame retardant , May 19, 2014.

- ↑ a b US EPA: Flame Retardant Alternatives for Hexabromocyclododecane (HBCD) , pp. 4–108, 4–121.

- ^ Dow implements polymeric flame retardant in Japanese XPS plants. In: Additives for Polymers. 2014, 2014, p. 8, doi : 10.1016 / S0306-3747 (14) 70076-4 .

- ↑ Dow: Polymeric Flame Retardant , accessed February 14, 2016.

- ^ Frank Esposito: Dow Chemical licenses polymeric flame retardant technology , Plastics News, July 22, 2013.

- ↑ Safety data sheet for FR-122P Compacted from ICL Industrial, accessed on May 30, 2017.

- ↑ FR-122P data sheet at ICL Industrial, accessed July 11, 2014.

- ↑ M. Schlummer, J. Vogelsang, D. Fiedler, L. Gruber, G. Wolz: Rapid identification of polystyrene foam wastes containing hexabromocyclododecane or its alternative polymeric brominated flame retardant by X-ray fluorescence spectroscopy. In: Waste Management & Research 33, 2015, pp. 662-670, doi : 10.1177 / 0734242X15589783 .

- ↑ D. Jeannerat, M. Pupier, S. Schweizer, YN Mitrev, P. Favreau, M. Kohler: Discrimination of hexabromocyclododecane from new polymeric brominated flame retardant in polystyrene foam by nuclear magnetic resonance. In: Chemosphere 144, 2016, pp. 1391-1397, doi : 10.1016 / j.chemosphere.2015.10.021 , PMID 26492426 .

- ↑ Christoph Koch, Milen Nachev, Julia Klein, Daniel Köster, Oliver J. Schmitz, Torsten C. Schmidt, Bernd Sures: Degradation of the Polymeric Brominated Flame Retardant “Polymeric FR” by Heat and UV Exposure. In: Environmental Science & Technology . 2019, doi : 10.1021 / acs.est.8b03872 .

- ↑ Christoph Koch, Bernd Sures: Ecotoxicological characterization of possible degradation products of the polymeric flame retardant “Polymeric FR” using algae and Daphnia OECD tests. In: Science of the Total Environment . 2019, doi : 10.1016 / j.scitotenv.2018.11.207 .

- ↑ BSEF Response to Inaccurate Environmental Health News article (United States) on Polymeric Flame Retardants . Bromine Science and Environmental Forum, 2019.

- ^ Open Letter of Concern on Flame Retardant Study . Dow Performance Building Solutions, January 22, 2019.

- ↑ BSEF response to publication “Ecotoxicological characterization of possible degradation products of the polymeric flame retardant“ Polymeric FR ”using algae and Daphnia OECD tests” . Bromine Science and Environmental Forum, 2019.