Printing press

A printing machine is a machine for printing on materials, the substrates . In contrast to the historical printing presses , the printing process is more automated .

history

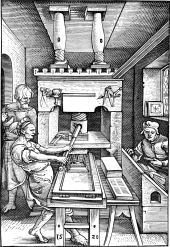

The first known printing press goes back to Johannes Gutenberg , who around 1442 used a screw press for the purpose of printing. In this early period, converted must or wine presses were often used for printing.

Development continued to increase the quality, speed and size of the prints. Although the manually operated hand presses have been replaced more and more by the printing machines, they are still occasionally used today for proofs (for correction) and very small editions.

In the older literature one can still find the term platen printing machine , although z. B. the hand crucible is usually a device in the sense of the definition. The first mechanical printing machine was patented in 1810 by the German Friedrich Koenig under the name Schnellpresse . Koenig created the world's first modern printing press factory in Oberzell ( Zell am Main ) near Würzburg . In 1845 there was another fundamental improvement through the development of the rotary press by Richard March Hoe , in which the paper runs between two cylinders rotating in opposite directions and is printed on by a cylindrically curved printing forme adjacent to one of the cylinders.

The development continued from a machine to an automatic machine .

Distinction

Nowadays, a large number of different printing machines are used, the design of which is based on the respective printing process implemented.

Differentiation according to the type of generation of the contact pressure

For the three different printing principles:

- Platen printing press (surface against surface)

- Cylinder printing press (cylinder against surface)

- Rotary printing machine (cylinder against cylinder)

Differentiation according to substrate

Offset printing machines based on the printing technology of rotary printing (round versus round), which can process webs of printing material ( web offset printing machines ) or sheets of printing material ( sheet-fed offset printing machines ), are of greatest importance .

Printing materials are usually paper, cardboard, various plastics and metals.

In sheetfed there are - depending on the maximum printable sheet format - the format classes small format, medium format, large format and super wide format.

Differentiation according to printing form (printing process)

In conventional, printing form-bound printing, one printing plate is exposed for each printing color ( substrate material usually aluminum). For offset printing (flat printing), this is done today using modern computer-to-plate (CtP) processes or directly in the printing machine (DI = Direct Imaging) with exposure by laser beam. A distinction must be made between printing form- related (offset printing, screen printing, letterpress , gravure printing) and non- printing form (digital printing with dry or liquid toners, e.g. HP Indigo , InkJet, etc.) printing processes.

- Letterpress - raised printing elements on the printing form (previously mainly called letterpress)

- Gravure printing - printing elements as a recess in the printing form

- Offset printing - printing method different on different wetting behavior based substances (oleophilic / hydrophilic), also known as indirect planographic printing designated

- Screen printing - screen printing process, the printing form is designed as a fine screen

Manufacturer

Some of the major offset press manufacturers are:

- Heidelberger Druckmaschinen AG (Germany)

- Koenig & Bauer AG (Germany)

- manroland sheetfed GmbH (Germany)

- manroland Goss web systems GmbH (Germany)

- Windmöller & Hölscher KG (Germany)

- Ryobi printing machines (Japan)

- Komori Lithographic Presses (Japan)

- Mitsubishi Heavy Industries (Japan)

- Beiren Group Corporation (China)

various

- The Museum of Printing Art in Leipzig shows numerous functional printing machines and presses.

Web links

- Detailed description of a sheet-fed offset printing machine (PDF; 8.7 MiB)

- Printing machine industry: Brutal remodeling recipe for survival, magazine article from Wirtschaftswoche on May 18, 2010

Individual evidence

- ↑ Hans-Bernhard Bolza-Schünemann : The Friedrich-Koenig-Gymnasium under the patronage of a brilliant inventor and technician. Excerpts from the speech […]. In: Kurt Fauster (Hrsg.): 5 years Friedrich-Koenig-Gymnasium. Würzburg 1978, pp. 4-7.