Electric contact

In electrical engineering , an electrical contact is used to establish an electrical connection between electrical components , between or within electrical circuits or within components such as contactors , relays or buttons / switches .

A distinction is made between non-releasable (fixed) and releasable contacts, switching contacts and sliding contacts .

Permanent contacts or connections

Insoluble connections are not absolutely insoluble; in order to solve them, however, an at least partial destruction of the connection is necessary.

- Solder connection (for example on circuit boards , with solder terminals, with solder lugs )

- Welded connection ( e.g. wire bonding )

- Press connection (press sleeve, connection of cable lugs to cables)

- Rivets

- Winding connection

- Adhesive connection

Connections that can be detached with tools

- Clamp connection

- Screw connection (e.g. busbars, screwing on cable lugs)

In a broader sense, soldered and wound connections also belong to the connections that can be detached with a tool ( connections that can be detached to a certain extent).

Detachable connections

Plug connections , screw connections with knurled screws or Edison threads ( lamps , screw locking devices) can be loosened by hand. Detachable connections have fewer operations than endure switch contacts, among them the preservation is the low contact resistance in the foreground. They are therefore often made of silver or gold-coated base materials. Other common coatings are tin and chrome . Uncoated, detachable plug and screw connections are made, for example, of copper , bronze or brass .

A stable contact resistance is an important feature for a good plug connection. Changes in contact resistance can have various causes. One of them is the electrical breakdown of high-resistance corrosion and foreign layers, also called frits . In order to eliminate the influence of fritting, the test current and the maximum permissible voltage drop are specified for tests of plug connections . A clear sign of fritting is a kink in the voltage and current characteristic, which indicates a jump in the contact resistance. The voltage at the contact is decisive for the change in the contact resistance due to fritting. In general tests of plug connections, fritting can occur due to the use of a measuring current that is too high and an open circuit voltage that is too high. The IEC512 Part 2 standard therefore stipulates a maximum measuring current of 100 mA and a maximum open circuit voltage of 20 mV for testing plug connections.

Switch contacts

Switching contacts can be found in contactors , relays , buttons / switches . They are the most demanding electrical contacts because they often have to maintain their mechanical and electrical properties over many millions of switching cycles :

- to avoid oxidation, they are corrosion-resistant ( precious metals ) or work under vacuum , protective gas or oil

- In order to avoid contact wear, they have a high melting point (tungsten) at high power

- To achieve a low contact resistance , they must be good conductive (copper, silver)

- they must not tend to weld (e.g. silver with an admixture of tin (II) oxide , previously cadmium oxide )

All of these properties cannot be combined in one switching contact, which is why switching contacts for high switching capacities are made of different materials than switching contacts for signals or low outputs. Switching contacts often also consist of material combinations (for example, precious metal-coated copper or bronze contacts for small capacities and porous tungsten contacts filled with silver for high switching capacities).

Gold-plated silver contacts are also common, which retain their low contact resistance (the gold layer) at low switching capacities and, as soon as they are used for high switching capacities, lose their gold layer and expose a robust silver contact. Switching contacts in relays and small switches are often designed in such a way that they can be used both for signaling purposes and for high switching capacities.

Despite its high conductivity, silver is only suitable to a limited extent for low switching capacities, as it forms silver sulfide layers.

The most important features of a switch contact specified by the manufacturer are:

- Switching capacity

- maximum switching voltage

- the thermally bearable continuous current

- the maximum switch-on and switch-off current to a particular load

Switching contacts (keys, keyboards) for high-resistance signals often consist of a pair of conductive rubber on the one hand and gold or graphite conductive paste on the other. They are particularly reliable and show little bouncing .

The bouncing of switching contacts is a periodic closing and re-opening at the moment of switching. With switching contacts for high switching capacity, it leads to increased contact erosion or even to welding ("sticking") of the contacts. Digital circuits sometimes work so quickly that, without countermeasures, the multiple contact with just one operation would be interpreted as multiple commands, which is why debouncing is necessary.

Sliding contacts

Sliding contacts (also sliding contacts) are used to contact moving parts. Examples are commutators , current collectors , slip rings and position sensors such as potentiometers or rotary encoders . Pairings made of copper / copper alloys and graphite as well as pairings made of precious metals are used.

Materials

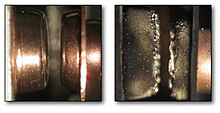

High demands are placed on the surface coating of electrical contacts, especially in the case of electrical relays with many switching cycles . At voltages above 50 volts and high currents, arcs are formed. They can melt the base material and promote oxidation of the surface. Tungsten compounds are resistant to high temperatures, but have very high contact resistances. A gold coating conducts well and protects against corrosion, but wears off quickly.

For low-power relays up to approx. 20 amperes, the alloy silver-nickel is a good compromise. For high loads (100 amps), cadmium oxide , alloyed with silver ( AgCdO ) is considered optimal to prevent the contacts from welding. On the other hand, the RoHS guidelines stipulate that cadmium should be avoided if possible. Tin oxide , also alloyed with silver (AgSnO2), is a good substitute.

Types of contacts according to their control logic

According to the logical switch-on behavior of the consumer or the load - according to positive or negative logic - a distinction is made between normally open (normally open contact, positive logic), normally closed (normally closed contact, negative logic) and changeover (one normally open contact and one normally closed contact with a common connection pole). The changeover contact consists of a linked normally open and normally closed contact, so it has both positive and negative logic at the same time .

This applies to all types of switches, on-switches, off-switches, changeover switches or changeover switches, buttons, relays and contactors.

Normally open or normally open contact (NO)

Many relays and contactors use working contacts or normally open contacts . If the necessary coil voltage is applied to the relay or contactor, the normally open contact is closed, i.e. it becomes low-resistance. The connected consumer or load now receives the supply current via the closed (low-resistance) working contact; the consumer is switched on. If there is no coil voltage, the normally open contact is open or has a high resistance; the consumer is switched off.

The connection of a closer is in English as NO (normally opened), so normally open titled. (With normally is unconfirmed meant.) If the relay is not energized (its spool so energized), this contact is open.

This type of contact is therefore always used when a consumer is to be safely switched off when the control voltage is not applied to the relay ("safety control"). For this reason, contactors in household and industrial electrical installations are preferably equipped with working contacts. This is security relevant.

Working contacts of semiconductor relays (mostly NO)

Industrial semiconductor relays usually always have normally open contacts as electronic contacts. The reason is the energy required in the control voltage (usually a direct voltage) to control the semiconductors. Without auxiliary energy, there cannot be an increase in conductivity in the semiconductor. But especially for low load currents, it is also possible to manufacture semiconductor relays normally on without control voltage applied by this so-called normally-on FETs or MOSFETs (depletion, Eng .: depletion (MOS) FET) are used, then in negative control logic via an optocoupler (whose load current is controlled to zero with the control voltage).

On the other hand, self-locking FETs or MOSFETs (enhancement MOSFET) are used in industrially manufactured semiconductor relays ( positive control logic ).

Normally closed or normally closed contact (NC)

The normally closed or normally closed contact is closed, i.e. low-resistance, when there is no coil voltage on the relay or contactor. In this case, the consumer depends on its operating voltage and carries the load current. It is on while the relay or contactor is off. If the coil voltage is switched on, the consumer is switched off. This is why normally closed contacts are also called normally closed contacts: While the relay is idle (off), the consumer carries the load current, i.e. it is switched on.

The connection of an opener is in English as , NC (normally closed) so normally closed titled. If the relay is not energized (its coil is de-energized), this contact is closed.

Changeover contact or changeover contact (COM)

Changeover contacts consist of a normally open contact and a normally closed contact that each share a pole, i.e. have a common pole. In the case of a relay or contactor with a changeover contact, initially - in the idle state, i. H. without coil voltage - the common pole of the changeover contact and the normally closed contact are connected to one another (low resistance). After switching on the coil voltage (energized relay), the common pole of the changeover contact is connected to the normally open contact (low resistance).

In English usage, the common pole of the normally open contact and the normally closed contact of a changeover contact is called common contact and is often abbreviated as COM .

The marking of the contacts of automotive relays is standardized according to DIN 72552 :

- 85 = relay coil, negative pole, (relay coil -)

- 86 = relay coil, positive pole, (relay coil +)

- 87 = connection of the changer, (COM: common contact)

- 87a = normally closed contact, (NC: normally closed contact)

- 87b = normally open contact, (NO: normally opened contact)

See also

- Bimetal corrosion (contact corrosion)

- Contact grease

literature

- Wolfgang Schufft (Ed.): Pocket book of electrical energy technology . Carl Hanser Verlag, Munich 2007, ISBN 978-3-446-40475-5 .

Web links

- Electrical Contacts Wiki (English)

Individual evidence

- ↑ a b c Basic Switch: NO, NC and COM Contact Terminal. Omron , accessed on August 5, 2020 (English, designation of switching contacts in English usage).