Grunt (fur)

Grotzen , also Krotzen (from Latin crux = cross), is the technical term in the fur industry for the middle of the fur with the darker, mostly long-haired stripe of the spine. If the grunt is very pronounced and narrow, it is called an eel line in zoology .

General

One of the first tasks a furrier does when making a fur is to mark the fur grump, the often very distinctive center of the fur. The grunt is usually darker than the rest of the coat, and, especially in the upper hair, longer-haired. Very many fur animals have the longest hair, apart from the tail, and the greatest density of hair in the grunt, especially after the back of the pumphead . In the middle of the grot, the hair is often shorter and tighter, and then increases in length on both sides and towards the back, for example in fox fur . However, there are a number of exceptions. Especially with nutria fur , the wool hairs are much thicker on the stomach than on the back. Since the belly (dewlap) of the nutria is therefore more important for the fur processing than the thin, sometimes almost bald grunt, nutria, together with the lynx fur and the desman fur, is one of the types of fur in which the round peeled fur is often cut open while grunting .

A characteristic of other types of fur is that a narrow strip of hair in the middle of the groan is longer, like a comb, in the case of the cat-like this is differently pronounced, as is the case with the goat skin . The fur mane on the neck of some animals is particularly long , such as horses . In cattle, on the other hand, the hair is parted there and two vertebrae are created, which are usually removed when the calfskin is processed. Basically, the hair direction of the animals eligible for fur processing runs from front to back in the grunt, with the exception of the above-mentioned deviation in the head area in a few species.

The leather of fur animals is usually thicker and less elastic when grunting than on the belly sides.

Usually the furrier uses the copy wheel to mark the groan . Despite its name, the Grotzenstecher is rarely used for this. If the groot's hair differs in length from the hair lying next to it or if the undercoat is darker, it can make sense to break the fur over the hand and mark the groot with pins (“bribe”). Another possibility is to mark with the pointed end of the skinning knife or the teeth of the furrier's brass comb, whereby the skin is pulled briefly over the worktop several times (the comb shown with a grunt is a special version). In any case, the resulting marking points are then connected with a suitable pen to form a dashed line on the leather side. If the print wheel used, by the inferiority of carbonless paper , this operation can be saved.

With full-skin processing, the groats are sewn on top of each other according to the groot lines, especially with distinctive groats they should run exactly in the middle of the fur strip. When stretching (" purposes ") the sewn fur, they are aligned to a straight line when straightening the fur with purpose nails, pins or purpose staples (tall staples). In the case of half-skinned processing, the fur is divided here. This is also the case when moving one half of the fur into the left and the other half into the right half of the garment in order to achieve a mirror-like appearance. During the previous sorting, you must ensure that the grot color is approximately the same, but above all that the hair is the same length. Curly skins are usually not added with a straight seam, but with a jagged point or wave to create a connection on the hair side that is as invisible to the eye as possible. The big point differs from the fur side point in that all the points are always the same length. Will collar and trimmings made of a skin, or in halbfelligen embellishments , the Grotzen is taken to the outside mostly because the relatively equally long and thick hair Grotz gives a cleaner edge than his thinning usually unequal and belly hair.

In the working technique of skipping , in which the skins are lengthened at the expense of the width, the cutting shapes (V-cut, A-cut, W- and M-cut) change the cutting direction in the middle of the groin. The now narrower grunt appears darker in the omitted fur strip than in the unprocessed fur.

Sheepskin from Montenegro with a tough, long-haired grunt, unlike other domestic sheep breeds

Dyed Blackcross mink coat with distinctive natural grotes

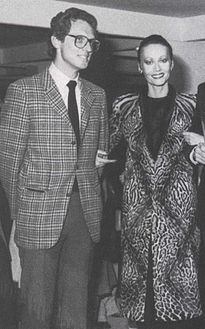

Special Grotzen tour with an ocelot coat for a furrier competition (1980)

Different grunting in two red fox skins

Derivatives

- The Grotzenstecher is a stabbing awl with a wooden or plastic handle on which there is a sharply pointed steel protrusion. It is used to mark the groan, color boundaries and hair imperfections (e.g. short-haired growth) from the hair to the leather side. The grotzen and colored lines drawn on the leather with the help of the small piercing holes enable the furrier to place the skins exactly next to each other and on top of each other, the damaged or imperfect areas are removed by breaking them .

- The Groot Drawing is the appearance of the Groot. The furrier speaks of the Grotzenlinie , when two or more skins placed one behind the other form a continuous Grotzen, for example with muskrat , Zyperkatzen , etc.

- The Grotzen fork is a working technique developed at the furrier school in Leipzig , but rarely used. In connection with the venting work , you let another or even three grunts run out of you. The fork can be made at any point, it can be carried out both downwards (usually) and upwards.

- The Grotzenstrich is the artificial coloring of a darker Grotzenstripe on a fur, the working technique itself is that

- Groot , also groot .On the one hand, there are skins that are not very lively, i.e. very uniformly colored (example: marble skin ). In order to make these monotonous furs in the processed fur part more attractive, an artificial, darker grunt is created in the fur refinement. This can be done either by spraying on with the spray gun, applying the paint with a brush, paintbrush, sponge or by machine with the brush roller. The fur refiner goes one step further, especially in the epoch of fashion, where narrow-striped fur processing is preferred (working technique of skipping) . After the pelts have been sewn together to form panels the size of a coat or jacket, so-called bodies , he applies several apparent groats per strip to the superimposed pelts at regular intervals, so that the actual width of the fur is no longer visible to the viewer. For thread grooming , the fur board is attached to a frame so that the spray gun can then be guided straight and evenly spaced with the help of tensioned threads.

- On the other hand, the natural grunt is sometimes not expressive enough for the fur designers (often with raccoon fur ), or it has been lightened or completely disappeared by bleaching or dyeing the fur. A natural-looking appearance is restored with a re-groot .

- Growing up requires considerable practice and skill, care must be taken that the color is not too dark, that it does not penetrate too deeply and that the smoothest possible, natural-looking gradient is achieved towards the sides. The dye solution should only color the tips and create an even transition between the upper and lower hair.

Individual evidence

- ↑ Hans Quaet-Faslem, Martin von Schachtmeyer: Pelz 1: Introduction to the technique of changing fur through cuts. 3rd edition, Zentralverband des Kürschnerhandwerk (Hsgr.), Bad Homburg, 1985, p. 84.

- ↑ a b c Fritz Schmidt: The structure of the fur fur . In: Das Pelzgewerbe Vol. XI / New Series 1960 No. 2, Hermelin-Verlag Dr. Paul Schöps, Berlin et al., Pp. 51-62.

- ↑ K. Toldt, Innsbruck: Structure and natural coloring of the hair coat of wild mammals . Publisher German Society for Small Animal and Fur Breeding, Leipzig 1935, p. 69.

- ↑ a b c Alexander Tuma jun: The practice of the furrier . Published by Julius Springer, Vienna 1928, pp. 84–85, 96, 110 (bribe), 224 (grotzieren).

- ↑ a b c d Alexander Tuma: Pelz-Lexikon. Fur and rough goods. XVII. Tape. Verlag Alexander Tuma, Vienna 1950. Keywords "Grotzen", "Grotzenlinie", "Grotzenstecher", "Grotzenstrich", "Grotzenziehen".

- ^ Author collective: Der Kürschner. Technical and textbook for the furrier trade. 2nd revised edition. Published by the vocational training committee of the Central Association of the Furrier Handicraft, JP Bachem Publishing House, Cologne 1956, p. 52.

- ^ Gerhard Spitzner: Felle Farben, Fantasy - The technique of dressing and the methods of dyeing . In: Felle, Farben Fantasy - A portrait of the German fur processing industry . Rifra Verlag, Murrhardt, p. 38.

- ↑ a b c Without indication of the author: BASF Guide for Fur Refinement . Badische Anilin- & Soda-Fabrik, Ludwigshafen am Rhein, undated (B 263 d / 1.61, 86743), pp. 54–55.