Holzwarth gas turbine

The Holzwarth gas turbine (named after its developer Hans Holzwarth , also known as the same-space , explosion or deflagration gas turbine ) is a development of the gas turbine in which the combustion takes place cyclically, as in an Otto engine , in a combustion chamber closed by valves . This design, developed from 1905 on, was the world's first large-scale gas turbine.

Since the closed combustion chamber has a fixed volume (“constant space ”), combustion takes place isochorically . By utilizing the pressure increase associated with isochoric combustion, the constant-space gas turbine, in contrast to modern constant-pressure gas turbines, does not require a compressor upstream of the combustion chamber .

Structure and functionality

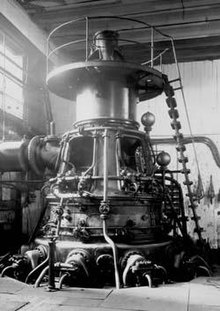

- First prototype, exhibited in the Deutsches Museum

The Holzwarth gas turbine is not a gas turbine consisting of a compressor and a gas expansion turbine in today's sense ; In many ways, the Holzwarth gas turbine has more in common with the clocked Otto combustion engine than with a modern gas turbine. Structure and process of Holzwarth gas turbine are derived from a gasoline engine, but for the removal of the mechanical work in the expansion of the gas not a piston but a turbine is used.

Construction and technical data

The gas turbines designed by Holzwarth initially had vertical waves , which were also common for steam turbines in the USA around 1900. Later, machines with horizontal shafts followed, especially for use as ship or rail drive.

In the vertical construction, the water-cooled combustion chambers with upstream air and combustion gas chambers and the inlet and outlet valves were arranged in a ring at the very bottom. Above that, in the middle, was the actual turbine with the exhaust system. The generator was placed on top by means of a lantern.

| parameter | First prototype | Second prototype |

|---|---|---|

| Construction year | 1906-08 | 1908 |

| partner | Körting | BBC |

| Power (theoretical / actual) [PS] | ? / 27 | 1000/200 |

| Number of combustion chambers | 6th | 10? |

| Pressure in the combustion chamber | up to 7 bar | ? |

| Speed [1 / min] | 3000 | ? |

Holzwarth cycle

The Holzwarth cycle (also known internationally today as the Humphrey process ) consists of four changes in state (phases):

| phase | Change of state | Technical process |

|---|---|---|

| 1 → 2 | Isentropic compression (mixture supply) | After opening the inlet valves, fuel and air flow into the combustion chambers (pilot system: six). The supply is initially almost pressureless by an external fan, later with a slight overpressure by an external compressor, driven by a steam turbine, which is fed from a waste heat boiler in the hot exhaust gas of the gas turbine. |

| 2 → 3 | Isochoric heat supply (combustion) | After closing the inlet valves, the mixture in the combustion chambers is ignited by means of a spark plug (pilot system: high-voltage magneto from Robert Bosch ). The temperature and pressure in the combustion chamber rise sharply (pilot system: xxx ° C and 4.5 bar). |

| 3 → 4 | Isentropic relaxation (work submission) | After opening the exhaust valves, the hot, pressurized exhaust gas flows out of the combustion chamber through a nozzle into the turbine (pilot system: two-stage Curtis turbine ), where it is relaxed by removing mechanical work. |

| 4 → 1 | Isobaric heat removal (exhaust gas removal) | After complete expansion, the hot exhaust gases flow from the turbine into the atmosphere, where they cool down. A cleaning cycle is carried out for flushing and cooling, during which the exhaust gases are completely expelled from the combustion chambers and turbine with fresh air. At the same time, the air is preheated, which is used as combustion air in the following cycle. |

The Holzwarth process thus largely corresponds to the Otto process , only when it comes to heat dissipation, which has little thermodynamic influence, it deviates and corresponds to the Joule process .

Although the isochoric heat supply theoretically enables higher efficiencies than the isobaric, the pilot plant only achieved an efficiency of about 13% due to the relatively low pressures and temperatures in the combustion chamber. During his experiments, Holzwarth was in contact with Professors Aurel Stodola and Wilhelm Schüle , who theoretically confirmed the measured values.

The first Holzwarth prototype from 1908 dispensed with isentropic compression (virtually pressureless purging of the combustion chamber), which means that it is a cycle with only three changes in state. This prototype can thus be referred to as a "three-stroke engine".

Comparison with the gasoline engine

The same-space gas turbine represents an intermediate stage between internal combustion engines and today's gas turbines with continuous combustion and an upstream turbo compressor. In many ways, the Holzwarth gas turbine has more in common with the Otto engine than with modern gas turbines:

| feature | Gasoline engine | Holzwarth gas turbine (same-space gas turbine) |

Modern gas turbine (constant pressure gas turbine) |

|---|---|---|---|

| Combustion chamber | completed by intermittent opening valves | open | |

| ignition | clocked by a spark plug | continuous (stationary flame) | |

| combustion | isochoric (constant volume, " equal space ") | isobaric (constant pressure, " equal pressure ") | |

| compressor | unavailable | Turbo compressor | |

| Power machine | Reciprocating engine | Gas expansion turbine | |

history

Around 1900 different engineers in Europe were working independently of one another on the development of a technically functioning gas turbine, as John Barber and others had described theoretically long before. In addition to Hans Holzwarth , these were in particular Franz Stolze in Germany, Ægidius Elling in Norway, Charles Lemâle and René Armengaud in collaboration with Auguste Rateau in France. One of the biggest problems for all inventors was the construction of the compressor. In contrast to the gas expansion turbine, which could be derived from already relatively mature steam turbines, compressors with high compression and economy were not yet developed at that time. The low internal efficiency of the turbo compressors available at the time meant that the compressor consumed all the energy supplied by the turbine, so that the machine could not do any work in total. Holzwarth circumvented this technical problem by simply adopting the same-space principle from the gasoline engine so that he did not need a compressor.

Holzwarth developed the theoretical concept for his gas turbine from around 1905, initially as an employee of the HOR company in the USA, and later independently back in Germany. He designed and built a first test machine with about 27 HP net power in the service of and for the account of Thyssen & Co .; It was manufactured and tested at Gebr. Körting AG in Hanover. This machine is exhibited today in the Deutsches Museum in Munich.

After the prototype had demonstrated the functionality of the principle, Holzwarth won the renowned turbine construction company Brown, Boveri & Cie. (BBC) in Mannheim and Baden / Switzerland as a partner for further development. Together with BBC, Holzwarth built further machines between 1909 and 1913 and developed a market-ready turbine, with the output increased to around 200 hp. Theoretically, the turbine should have delivered up to 1000 hp; due to the large waste heat losses and the power requirement of the compressor, only a fraction was achieved. After an interruption due to the First World War, development continued from 1918. The technology was boosted by interest from the Prussian State Railways and the Imperial Navy , which placed orders for test machines to drive locomotives and ships. In 1920 a machine was delivered to the railway. The test showed, however, that the gas turbine was clearly inferior to the competing technologies of the steam turbine and diesel engine.

Together with BBC, Holzwarth designed a further developed Holzwarth gas turbine with two series-connected combustion chambers and a theoretical 5000 hp / practically 2000 hp output, which was operated from 1933 in the Thyssen steelworks in Hamborn, initially with oil and later with blast furnace gas.

The end of the short period of equal-space gas turbines began to be seen in the late 1920s, when, following an improvement in turbo-compressors, the equal-pressure gas turbine gained more and more the upper hand and finally prevailed. After 1933, the BBC also switched to the principle of equal pressure, the development of which BBC itself had significantly advanced with Adolf Meyer . A last equal space gas turbine with 5000 HP, which was completed by Holzwarth in 1939, could only be tested at part load due to a lack of fuel gas and was finally destroyed by a bombing during the Second World War .

In recent times there again research projects, a pulse jet engine (Pulsed Detonation Engine) to combine with discontinuous combustion with an expansion turbine, which is a step back towards Holzwarth gas turbine.

Individual evidence

- ↑ a b First Holzwarth experimental gas turbine, 1908. Deutsches Museum, accessed on February 10, 2011 .

- ↑ a b c d e Gustav Goldbeck: Holzwarth, Hans. In: New German Biography (NDB). Volume 9, Duncker & Humblot, Berlin 1972, ISBN 3-428-00190-7 , p. 581 ( digitized version ).

- ↑ Principle of the Holzwarth gas turbine. from: Die Technik , Verlag Technik, 1948, p. 388. (No longer available online.) Formerly in the original ; Retrieved February 10, 2011 . ( Page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ Hans Holzwarth, August Schilling: Multi-stage explosion turbine plant for generating driving gases . United States Patent No. 2791884. May 14, 1957 ( full text on freepatentsonline.com).

- ^ A b Norman Davey: The Gas Turbine - Development and Engineering . Watchmaker Publishing, 2003, ISBN 978-1-929148-20-2 , pp. 2 ( limited preview in Google Book search).

- ^ Richard A. Zahoransky: Energy technology . (Section 6.1.1 Gas turbines with isochoric heat supply ). 2nd Edition. Vieweg + Teubner, 2004, ISBN 978-3-528-13925-4 ( limited preview in Google book search).

- ↑ a b ASME , Alstom (ed.): THE WORLD'S FIRST INDUSTRIAL GAS TURBINE SET - GT NEUCHÂTEL . Alstom (Switzerland) Ltd., Baden 2007 ( full text (PDF file; 110 kB) on asme.org).

- ^ A b E. L. Cornwell: The Illustrated History of Ships . Octopus Books, 1979 ( excerpt from houseofdavid.ca).

- ^ Ian McNeil (Ed.): An Encyclopedia of the History of Technology . Routledge Companion Encyclopedias. Routledge, 2002, ISBN 978-0-203-19211-5 ( limited preview in Google Book Search).

- ↑ Julius Kruschik: The gas turbine: Your theory, construction u. Application f. stationary systems, ship, locomotive, motor vehicle u. Aircraft propulsion . Springer, Vienna 1952.

- ^ F. Schauer, R. Bradley, J. Hoke: Interaction of a Pulsed Detonation Engine with a Turbine . AIAA 2003-0891. 2003.

- ↑ Takashi Sakurai et al .: Experimental study of Pulse Detonation Turbine Engine toward Power Generator . ( Full text (PDF file; 358 kB) on caltech.edu).

literature

- Manfred Busch: The Holzwarth gas turbine . In: Stuttgart technical history lectures 1980/81 . 1981, p. 161 ff .

- Hans Holzwarth: The gas turbine: theory, construction and operating results of two executed machines . R. Oldenbourg, Munich / Berlin 1911, OCLC 39934475 ( full text in the Internet Archive ).

- Hans Holzwarth, W. School: Thyssen-Holzwarth oil and gas turbines . In: Journal of the American Society for Naval Engineers . tape 34 , Issue 3 (August 1922), 1922, pp. 453-457 .

- Holzwarth Gasturbinen GmbH, Mülheim-Ruhr (Hrsg.): The development of the Holzwarth gas turbine . Bagel, 1938, OCLC 248715868 .