Langmuir layer (incandescent lamp)

The Langmuir layer describes an area around the filament or filament in which there is practically no convection (flow) of the filling gas. Their discovery goes back to observations made by Irving Langmuir at General Electric in 1912 and was an important finding in reducing energy loss through heat dissipation. By twisting the filament and introducing an inert gas, it was possible to increase the light output and the service life of the incandescent lamp.

Background to research by Irving Langmuir

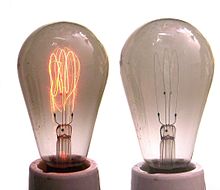

In an incandescent lamp , a tungsten filament through which electricity flows emits light. Modern lamps that are operated with a mains voltage of 230 V typically have a very long, thin filament - finer than a human hair and with a length of around 1150 mm . In the first incandescent lamps, the filament was hung loosely or stretched in a zigzag pattern.

To an oxidation of the wire by means of oxygen to avoid was at the first light bulbs inside the glass tube a vacuum . However, the negative pressure has the disadvantage that tungsten atoms in the wire evaporate unhindered and are deposited as a dark coating on the inside of the glass bulb. The transparency of the glass is reduced. At the same time, the wire quickly burns through the removal of material and limits the service life of the lamp, especially with higher radiation output .

Langmuir's task was initially to study the cause of the formation of the dark film and to find possible influencing factors. He then experimented with numerous filling gases available to him while varying the filling pressure. He found that traces of water in the residual gas in particular significantly increase the formation of deposits. Due to the heat, the water near the glow wire is split into oxygen and hydrogen . The tungsten reacts with the oxygen. The resulting molecules are accelerated to the outside and are deposited as a thin tungsten oxide layer on the colder inside of the glass bulb. The free hydrogen reduces the oxide to metallic tungsten that appears dark, which in turn creates water that is available for a new reaction on the glow wire. Even with a good vacuum, the effect could only be reduced slightly, but not prevented.

On the other hand, Langmuir's experiments showed that the evaporation of tungsten on the filament is significantly reduced when the glass bulb is filled with nitrogen . This inert gas itself does not react with the tungsten. Rather, many of the tungsten atoms emitted by the filament collide with the gas atoms and are reflected back to the wire. The service life of the incandescent lamp increases. On the other hand, the gas filling, in contrast to the vacuum, clearly dissipates heat. In order to bring the filament to the same brightness as in a vacuum, a significantly higher energy supply is necessary. The efficiency of the incandescent lamp is reduced. Unlike in a vacuum, this effect can be influenced by the arrangement of the filament in the lamp.

The Langmuir layer

The filament gives off heat to the gas layer surrounding it. This layer in turn heats the next layer. In this way, the heat is conducted further and further outside.

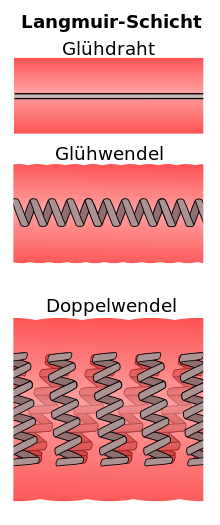

As the temperature rises, the viscosity of the gas increases. The viscosity effect in gases arises from the increasing exchange of momentum between the gas particles due to increased molecular movement. Given the high temperatures prevailing on the filament, a first approximation of a static gas layer of 1–2 mm thickness can be assumed, which is in the form of a cylindrical sheath around the filament. This shell is called the Langmuir layer after its discoverer.

Due to the high viscosity of the gas, there is no heat transfer by convection (flow) within the Langmuir layer . As a result, the thermal conduction - in addition to the dominant but unavoidable thermal radiation - becomes the mechanism by which the filament gives off heat to the filling gas surrounding the Langmuir layer. The heat loss can be approximated using the following formula:

where a constant represents the length of the wire, the thickness of the wire and the thickness of the Langmuir layer.

In order to keep the heat loss low, the surface of the cylindrical casing must consequently be as small as possible and, above all, its length must be as short as possible. If the light wire is long and thin, as was customary up to then, the heat is dissipated to the outside along its entire length. The thickness of the filament, on the other hand, has a significantly smaller influence on the size of the Langmuir layer. If the filament is replaced by a fine, spiral-shaped filament , the Langmuir layers of the individual wires overlap and a cylinder with the outer diameter of the spiral can be assumed for the entire arrangement of the wires. In this way, long thread lengths can be achieved with low heat loss.

To intensify the effect, especially in the case of incandescent lamps with a higher operating voltage , such as when operating on a mains voltage of 230 V, the filament is designed in the form of a double coil. The transition from a single tungsten filament to a double filament resulted in a 20% gain in light output and was implemented from 1932 onwards. By using krypton instead of argon as the filling gas, the loss of heat conduction due to the higher atomic mass can be further reduced, so that an additional 7% more light output can be achieved with the same service life.

Influence on the manufacture of light bulbs

Langmuir filed a patent in America on April 19, 1913, entitled Incandescent electric lamp , which was granted on April 18, 1916 under patent number 1180159. It contains incandescent lamps with tungsten filaments that are filled with a gas that has relatively poor thermal conductivity.

The first tungsten lamps filled with nitrogen gas at almost atmospheric pressure came onto the market in 1913 as 1000 W and 750 W versions. To distinguish them from vacuum lamps, they were given the name Mazda C in America . Further variants with an output of down to 200 W followed in 1914. From around 1918, part of the gas filling was replaced by argon and smaller lamps with an output of 40–50 W were also offered as gas-filled lamps.

The increase in the efficiency of the light bulbs was crucially dependent on the output. While the light output of the gas-filled high-performance lamps with a service life of around 1000 hours was around 20 lm / W ( lumens per watt), compared to a vacuum lamp, a 100 W lamp only increased by around 10 in 1917 Realize lm / W to 12.5 lm / W.

A problem at the time was the tungsten wire sagging during operation. This limited the minimum distance between the turns of the coil. It was not until 1917 - also by a General Electric employee - a new alloy was developed for the wire that a changed crystal structure in the metal prevented mutual displacement within the material and thus ensured stability. This discovery only made it possible to develop a long-term stable double filament in 1926. From 1936, standard incandescent lamps with double filaments could be produced in series. This change from a single helix to a double helix made it possible to increase the temperature of the wire while maintaining the same service life. The light yield increased with a 60 W lamp from 12.5 lm / W to 13.8 lm / W, that of a 100 W lamp from 15.3 lm / W to 16.0 lm / W.

literature

- H. Schirmer, I. Stober, J. Friedrich: About the method of Langmuir for the theoretical treatment of gas-filled incandescent lamps. In: Technical-scientific treatises of the Osram-Gesellschaft. Volume 9, 1967, pp. 125-136 ( preview ; for the theoretical calculation of the Langmuir layer).

Web links

- JD Hooker: Filament Coiling Effects. Museum of electric lamp technology, accessed on December 9, 2012 (English, illustration of the cooling effect depending on the shape of the filament).

Individual evidence

- ↑ a b Rainer Dohlus: Photonics: Physical-technical fundamentals of light sources, optics and the laser . Oldenbourg Wissenschaftsverlag, 2010, ISBN 978-3-486-58880-4 , p. 119 ( limited preview in Google book search).

- ^ JD Hooker: Gas Filling Effects. Museum of electric lamp technology, accessed January 6, 2014.

- ↑ a b c Kamesh Roy: Illuminating Engineering . Laxmi Publications, 2006, ISBN 978-81-7008-898-1 , pp. 19-25 (English, limited preview in Google Book Search).

- ^ A b c d Arthur A. Bright Jr .: The Electric-lamp Industry: Technological Change and Economic Development from 1800 to 1947. Massachusetts Institute of Technology, The Macmillian Company, New York, 1947, pp. 317-329 ( online version as PDF (15.5 MB)).

- ↑ a b H. Remané: The Osram half-watt lamp. In: Polytechnisches Journal . 329, 1914, pp. 53-56.

- ^ Carl Kramer, Alfred Mühlbauer (Ed.): Practical Guide Thermoprocess Technology: Basics - Processes , Vulkan Verlag, Essen 2002, ISBN 3-8027-2922-6 , p. 182 ( limited preview in the Google book search).

- ↑ Uni Bayreuth: Chemistry in incandescent lamps: 5. The service life of incandescent lamps. ( Memento of the original from June 22, 2012 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. September 20, 2010, accessed December 23, 2013.

- ↑ Ullman's Encyclopedia of Industrial Chemistry. Urban and Schwarzenberg Verlag 1960, section light generation and light measurement , pp. 709 and 717.

- ↑ Patent US1180159 : Incandescent electric lamp.

![{\ displaystyle W \ approx c \ cdot l \ cdot {\ sqrt [{3}] {\ frac {r} {R}}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/5876f51af5ea127f01a5122684127680394a05d6)