Measuring recorder

Measuring recorders are writing measuring devices that record the temporal course of the measured variable directly in a line diagram on paper webs. Functionally, they can be replaced by the more powerful data loggers and in some applications also by digital storage oscilloscopes .

Pointer deflection

Hot wire

The pointer, which also carries the pen, was deflected by hot wires (see hot wire instrument ) , especially in the early years of electrical engineering , as only they applied the relatively high force that the pen needed to move. The long response time was a disadvantage.

Hot wire instruments show the rms value of a current or a voltage.

Electrodynamic and -magnetic deflection

The pointer is electrodynamically driven with a large moving-coil measuring mechanism or a moving coil. The method is only suitable for point recorders , since only here the force on the pointer or pen is zero.

The same applies to electromagnetic drives such as moving iron measuring mechanisms . Moving iron measuring mechanisms also record the effective value.

Compensation recorder

With the advent of affordable amplifier technology, the compensation recorder prevailed. In this case, the pointer is driven by a small electric motor that drags the pointer over a cable. With the pointer position, a resistor ( potentiometer transmitter ) is also adjusted, which supplies the actual value to a differential amplifier. This is constantly compared with the measured value according to the principle of voltage compensation . If there are deviations between the measured value and the actual value, the amplifier readjusts the pointer position via the motor current. Such recorders can still record changes in measured values of a few milliseconds.

With compensation recorders, alternating or real multi-channel versions are possible. Most have two channels, but there are also those with eight or more fair inputs.

Further pointer drives

The following non-electrical quantities can drive the pointer or pen of a writer (examples):

- Humidity (principle of the hair hygrometer )

- Pressure ( pressure cell ), derived from this e.g. B. the flight altitude (barometric altimeter ), the airspeed ( pitot tube ); see flight recorder .

recording

Line recorder

A line recorder continuously writes a measured value curve as a function of time on a roll of paper. The first line writers wrote with a wafer-thin glass tube, which is attached to the measuring tool and used the special ink to write on the paper. Additional mechanics are required to write the pointer deflection of the measuring mechanism on the paper linearly and not in a semicircle. Because the friction of the glass tube on the paper prevented the measuring mechanism from deflecting the pointer, large measuring mechanisms are required. Only the paper advance enables a reasonably accurate pointer deflection, as this deflects the friction. Compensation recorders avoid this problem.

Point recorder

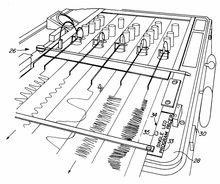

Point recorders were developed to keep the pointer moving freely in moving iron or moving-coil measuring mechanisms. At certain time intervals the pointer, which could move freely over the paper at a small distance and was provided with a punctiform elevation, was pressed onto a ribbon by an electromagnet or a mechanically driven clockwork. Through the ribbon, the dot on the pointer stamped a dot on the paper. By using multicolored ribbons that were switched in the same cycle as the various measuring inputs, several curves could be recorded at the same time. However, this method was only suitable for processes that run slowly, as measured value peaks were "swallowed" during the switchover pauses. The feed rate was chosen so that the individual points resulted in a closed line. Older flight recorders also worked according to this principle .

The creation of the dots was partly achieved by pulsed electrical discharges ( sparks ). The drawing point can always move freely.

Drop clip writers are also point writers. They are a further development of the line recorder, but get by with much smaller measuring mechanisms because the pointers can move freely. Due to the long pointers, no linearization is necessary. To write, a drop bracket falls on the pointer of a measuring mechanism at regular intervals. The printer tape below describes the running paper strip, which is moved by a synchronous motor. The feed speed of the paper can be changed by moving gears. With the multi-channel swing recorder, up to 6 measured values are written in different colors one after the other through input switching and color band switching. This means that 6 different measured values can be recorded on a paper tape.

Paper feed

Drives

Spring mechanism

Autonomous writers (e.g. moisture recording in museums) are often driven by a spring mechanism or a mechanical clockwork. Such writers work with an elevator for about 1… 2 weeks, the winding coincides with the exchange of the written paper.

DC motor

For this purpose, DC motors are equipped with a centrifugal governor. Older flight recorders were z. B. so driven.

Synchronous motor

The paper feed is carried out with synchronous motors with constant speed (coupling to the mains frequency ), which are geared down. The feed could be adjusted in steps by sliding gears (gearbox).

Stepper motor

Today, stepper motors are mostly used to advance the paper. Their speed can be adjusted very precisely electrically over a wide range with the aid of quartz-controlled oscillators and frequency dividers without having to switch gears.

Transfer of the feed

The feed is transmitted to the paper web via gears and sprockets. The pin wheels prevent slippage and skew of the paper.

Feed rate

The feed speed ranges from a few millimeters per hour to around one meter per second. For special measurements or for troubleshooting, significantly larger or smaller feed rates may be required.

The readings from a few minutes, hours or days in the past are visible on the writing surface or a cylinder.

Writing paper

Wood-free paper is used for recorders, on which the scale of the measuring recorder is printed over the entire length of the strip so that the measured values can be read at every point on the strip. Time intervals are marked across the track. The two long edges are perforated. The sprocket wheels of the feed rollers engage in this perforation.

Coated colored paper is sometimes used, whereby the coating is removed by pressing the pointer and the measurement curve becomes visible as a colored line.

Input signals

Measuring recorders for industrial use are designed for the standard signals 0 ... 20 mA or 4 ... 20 mA used in measurement and control technology . So all other types of signals have to be adapted via isolation amplifiers or similar assemblies.

Special designs

Multiple measuring recorder

For test purposes or for troubleshooting, devices that can process different types of signals are required. Similar to multimeters , they have different input ranges for current, voltage, resistance or other electrically measurable variables. In addition, its feed range can be varied very widely so that both fast and slow changes can be visualized well. All settings can be changed without interfering with the device.

XY recorder

These recorders have a second measured value axis instead of the time axis. You have no advance, but the writing surface is covered with a sheet of paper. They are ideally suited for recording characteristic curves, as one variable can be represented as a function of a second variable. The technology is similar to that of digital plotters , but they work with analog input signals. The paper is usually fixed to the base plate with an electrostatic charge.

Digital measuring recorder

With the advent of computer technology, it became possible to translate measured quantities into binary format and save them using analog-digital converters . Using the appropriate software , these values can then be processed so that they can be displayed as line diagrams on the screen. Compared to conventional recorders, they have the following advantages: high speed (up to several billion measurements per second), good archivability, no paper consumption and, thanks to the measured values in numbers, good statistical evaluability. That is why they are gradually replacing the older generation of writers in the industry. If a paper printout of a measurement curve is required, this can be obtained, as with other computer graphics, with the aid of a graphics-capable printer or a plotter .