Medium caloric power plant Bremen

| Medium caloric power plant Bremen | |||

|---|---|---|---|

| location | |||

|

|

|||

| Coordinates | 53 ° 7 '27 " N , 8 ° 43' 37" E | ||

| country |

|

||

| Data | |||

| Type | Medium calorific power plant | ||

| Primary energy | Secondary fuel | ||

| fuel | medium calorific waste | ||

| power | 29.3 MW electr. | ||

| owner | swb Disposal GmbH & Co. KG | ||

| operator | swb Disposal GmbH & Co. KG | ||

| Project start | 2005 | ||

| Start of operations | 2009 | ||

| Website | Power plant side at swb | ||

| was standing | November 19, 2011 | ||

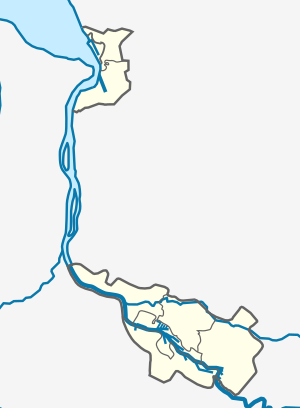

The Mittelkalorik-Kraftwerk Bremen (MKK) is a substitute fuel power plant in the Bremen district of industrial ports in the direct vicinity of the Hafen power plant and also on its premises. The MKK, which went into operation in 2009, is the second waste incineration plant to generate electricity in the city of Bremen after the waste incineration plant .

history

The first preliminary project planning began in summer 2005 and continued until the end of the following year. In spring 2006, the swb supervisory board approved the investment of around 110 million euros. In December 2006, the necessary basic capacity utilization of 60 percent over a period of ten years was achieved and the placing of the individual contracts began. This process dragged on until August 2007 and had become necessary as no general contractor could be found. Construction finally began in January 2007. In July, the approval for the Federal Immission Control Act was available and further medium-term contracts could be concluded, while the occupancy rate had meanwhile risen to 90 percent. The cornerstone ceremony took place on September 7, 2007 . In December of the same year the first boiler support was installed; The assembly of the grates was completed in January 2008 and the construction of the garbage bunker at the beginning of March. Two so-called fuel cranes were delivered in June and installed, and on July 5, the boiler passed the bar performed at a test pressure of 101 pressure test . On the night of 3 to 4 September sent by heavy transport the 38-ton condenser delivered. It has a length of 7.50 and a width of 4.20 and a height of 4.70 meters. It was originally constructed in northern Italy, but initially received 6,921 additional titanium tubes welded on at the Mittelbüren power station over a period of several weeks . These significantly increased the original weight of 31 tons. The so-called cold commissioning already took place in October and in November 2008 the medium-caloric power plant in Bremen was considered completed, but was not yet fully operational. Between December 3rd and 19th, the obligatory boiler blowing was carried out in order to remove small-grain mineral impurities that could not be rinsed out with steam. The noisy procedure was limited to the working days on which a maximum of two blowing processes of ten minutes each were initiated.

In January 2009, when the first waste fire was ignited, cold start-up switched to warm start-up for trial operation without a turbine - the power plant has been operating in combustion mode since then. The trial run lasted from April to mid-June. The delivery and installation of the turbine was delayed by around six months due to production, so that it only arrived at the MKK in July 2009 and could be installed. It was first approached on August 24th and officially put into operation four days later on August 28th. At the beginning of March 2010 it started its trial operation and since June 2010 it has been in regular operation.

functionality

Household and commercial waste serve as fuel. The power plant is designed for the medium caloric range . This secondary fuel is primarily a mixture of paper, plastic, wood and packaging scraps that can no longer be recycled . These sorting residues mainly come from commercial waste sorting plants and mechanical-biological waste treatment plants. Compared to normal incineration waste, medium calorific value has a higher calorific value ; it is about half as high as that of hard coal .

With a net efficiency of 27 percent and an output of 29.3 MW, the power plant generates around 234.4 MWh annually and with this production could cover the needs of 91,000 private households in Bremen. In fact, however, the majority of the energy is required for internal use and also covers around two thirds of the electricity requirements of units 5 and 6 of the hard coal-fired power station in the Hafen area. By using the medium calorific value, 90,000 tons of coal can be saved within one year with the same electricity production. In addition, the MKK's steam cycle has been integrated into the steam network of the neighboring power plant since mid-2009. In this way, the steam additionally produced in the MKK can be diverted to blocks 5 and 6 for support. In this way, around 80 to 90 tonnes of live steam per hour (of around 127) at 40 bar and 400 ° C can be thermally utilized to cover the coal blocks' own needs.

As a single-line system, the MKK only has a single, water-cooled moving grate - however, it has three lanes and is therefore unusually wide. With a design calorific value of 14 MJ per kilogram (calorific value window from 11 to 20 MJ / kg), around 226,000 tons of waste are recycled per year in base load. Every day between 680 and 720 tons of medium caloric burns, the size of which must not exceed an edge length of fifty centimeters. They are hoarded in two so-called garbage bunkers, the first of which holds 4,000 cubic meters and the second 10,000 cubic meters . From Monday to Friday, around 1000 tons of medium caloric are delivered in the 14 hours of daily opening times. In some cases, delivery peaks of up to 1,500 tons per day can be handled, which is roughly equivalent to the load of 75 trucks.

The MKK's flue gas cleaning takes place in four successive steps. First, ammonia water is injected into the hot exhaust gas flow via an SNCR (Selective Non-Catalytic Reduction) system to reduce nitrogen oxides. This is followed by two stages of a quasi-dry process: First, a spray absorber ensures that milk of lime is injected, and then a deflecting reactor that injects dry lime and activated coke . Finally, reaction residues are separated off by means of a fabric filter, and the absorber recirculates into the diversion reactor.

Individual evidence

- ↑ Corinna Laubach: "Electricity is generated from waste" on Kreiszeitung.de ( Kreiszeitung Syke from August 29, 2009. Found on November 22, 2011)

- ↑ Jens Uwe Meyer: "The MKK medium-caloric power plant - from planning to commissioning" (PDF file; 7.0 MB). PowerPoint presentation dated February 26, 2009. Retrieved November 20, 2011

- ^ Swb press release from June 26, 2009