Mercury vapor rectifier

A mercury vapor rectifier is a historical type of rectifier that converts alternating current or three-phase alternating current into direct current. The functional principle was developed by Peter Cooper-Hewitt and patented in 1902. The mercury vapor rectifier is a special design of a gas discharge tube and dominated parts of power electronics until the early 1970s .

Historical

Mercury vapor rectifiers were used to generate direct current at higher voltages until the 1970s , e.g. B. Power converters for the energy supply of trams and suburban trains , for the power supply of the tube output stages of large transmitters . Phase angle controls with controlled mercury vapor rectifiers were used for controllable drives of machines; these were designated as ignitron or thyratron depending on the structure .

Since the 1960s, mercury vapor rectifiers and thyratrons have been supplanted by silicon rectifiers, thyristors, and insulated gate bipolar transistors (IGBT), which are beneficial in every way: lower forward voltage , smaller volume, non-fragile, non-toxic. The last domain of the mercury vapor rectifier was high-voltage direct current transmission (HVDC) until 1975.

construction

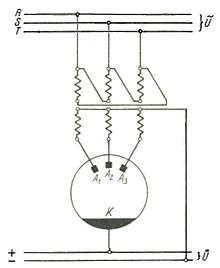

A mercury vapor rectifier consists of a glass bulb with a mercury lake at the bottom as a cathode . A glass dome arches above it, on the inner wall of which the mercury that evaporates during operation condenses again and flows downwards. Heating electrodes are attached just above the mercury lake to vaporize some mercury and make the rectifier ready to start. At the sides, glass extensions are fused, resembling the poor and wearing graphite electrodes as anodes at their ends . The number depends on the intended use: If direct current is to be generated from alternating current, one or two “arms” are used, depending on whether one or both half-waves of the alternating current are to be used. With three-phase alternating current there are three or six “arms”. Six “arms” = anodes are used to reduce the residual ripple of the resulting voltage ( six-pulse circuit ). In the six-phase arrangement, the three secondary windings of a three-phase alternating current transformer are divided into two parts by halving each, the midpoint connections of the secondary windings are connected and form the negative DC voltage connection, while the cathode of the rectifier represents the positive connection. For rectifiers with a particularly high output, a metal housing with glass bushings is used instead of the glass bulb.

functionality

principle

Mercury vapor rectifiers belong to the subgroup of electron tubes with a mercury cathode and as such are a special form of cold cathode tubes.

With this type of tube, the electron source is the base of the mercury vapor arc in operation, the so-called cathode spot (also known as the plasma cathode). The positive mercury ions flowing towards the cathode with high kinetic energy form a concentrated space charge and a strong electric field in the area in front of the cathode spot, which in connection with the kinetic collisions of the ions allows more electrons to be emitted from the liquid mercury (cathode). Special constructive measures such as angled anode arms must ensure that no mercury droplets can reach the anode connections directly. If this were the case, the mercury ions in front of the anode would cause so-called reignitions between the anode and cathode or between neighboring anodes.

An ignition process is necessary to build up the ion current (arc). Single-anode rectifiers must be re-ignited in each period, with multi-anode rectifiers the arc jumps from one anode to the next.

Excess mercury vapor condenses in the bulb dome during operation, so that a stable equilibrium between liquid mercury and the mercury vapor is established in the flask.

Startup process

A mercury vapor rectifier must similar to a fluorescent lamp started be. This is done by a starter electrode that is attached just above the mercury lake. To start, the electrode is energized and immersed in the mercury (e.g. using an electromagnet or by tilting the glass bulb). As soon as it loses contact with the mercury, a spark forms, which ionizes the mercury vapor and allows the main current to flow to the anodes. As soon as the rectifier works, enough ions are continuously supplied from the mercury cathode to maintain the space charge in the area of the cathode spot. The starter electrode is then no longer needed in multi-anode rectifiers.

With mercury vapor rectifiers that work with small load currents, there is a risk that the gas discharge and thus the cathode spot will go out. In order to avoid this, an auxiliary discharge and thus the cathode spot are maintained by an auxiliary device. It consists of a short-circuited M2 rectifier circuit whose alternating current is inductively limited. This auxiliary device is also necessary for single-anode vessels.

business

The continuous discharges inside the glass bulb generate heat, which ensures that the mercury continues to evaporate. Evaporated mercury is deposited on the glass dome, condenses and flows back into the lake. So there is an easily ionizable mercury atmosphere.

If a direct voltage is applied from the outside so that the cathode has a negative voltage compared to the anode, an electron pressure / excess of electrons is created at the cathode (mercury lake) . The electrons ionize the mercury atmosphere and migrate to the anode, which is currently positively charged. A current can thus flow in the external circuit. The mercury atoms emit a bluish light. If the direct voltage is applied the other way around, hardly any current flows in the opposite direction and / or between the anodes, since they are less inclined to give up electrons due to their passivation , whereas these emerge more easily from the mercury lake. So the arrangement acts as a rectifier.

In the case of controllable mercury vapor rectifiers, a positive voltage on the control electrode (referred to as a grid) is necessary to achieve a discharge. After ignition, the current flow through the mercury vapor rectifier can no longer be controlled with the help of the grid - it flows until the alternating current crosses zero and is re-ignited shortly after the start of the next half-wave. In this way, the current (like a thyristor ) can only be switched on but not switched off.

Mercury vapor rectifier with six anodes from the Bavarian Zugspitzbahn

Efficiency

Almost independent of the anode current, the voltage drop between anode and cathode, the so-called operating voltage , is around 12 V. At a current of 500 A, this means a power loss of 6000 W, which has to be dissipated by water cooling. With lower currents, air cooling may be sufficient.

This comparatively very high loss means low efficiency and could only be tolerated in high-voltage systems (over about 100 V), but not in the case of low voltages such as in chargers . The invention of the semiconductor rectifier with considerably lower voltage drops (around 1 V) and thus considerably better efficiencies replaced the mercury vapor rectifier in a very short time.

Specialty

Due to the electrical excitation of the mercury and its property of emitting visible light, a running mercury vapor rectifier glows and flashes in light blue light, which like a fluorescent lamp has a high proportion of ultraviolet radiation (UV). The cathode spot on the surface of the mercury lake can be observed as a wandering, green glowing spot. At this point the electron flow emerges from the metal.

Others

The largest mercury vapor rectifiers ever used were used at the Nelson River Bipol .

Controllable types of mercury vapor rectifiers are the thyratron , the ignitron and the excitron .

Other types of rectifiers were used to charge accumulators , including the so-called " Tungar tubes ", which were able to deliver the required current at the relatively low charging voltages (e.g. 12 volts ).

Popular culture

In some Frankenstein films, multi-anode mercury vapor rectifiers are shown.

Web links

- http://www.hts-homepage.de/TechnischesMuseum/TM20.html - Mercury vapor rectifier

- http://www.hts-homepage.de/Klingerpark/Klinger5.html - mercury vapor rectifier in action

- Detailed information and lots of pictures

- http://www.electricstuff.co.uk/mercarc.html - website on the subject of mercury vapor rectifiers

- Virtual museum about mercury vapor rectifiers

Individual evidence

- ↑ Patent GB190304168 : Improvements in the Method of and Means for Obtaining Uni-directional Current from a Single-phase or Poly-phase Alternating Current Source. Registered on October 30, 1902 , inventor: Peter Cooper-Hewitt.

- ↑ Movie Madness # 16: Evil of Frankenstein ( English ) Retrieved September 24, 2019.