Renate colliery

| Renate colliery | |||

|---|---|---|---|

| General information about the mine | |||

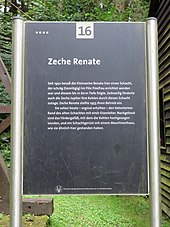

| Engine house of the Renate colliery (replica) | |||

| Funding / year | Max. 23,526 t | ||

| Information about the mining company | |||

| Employees | Max. 58 | ||

| Start of operation | 1950 | ||

| End of operation | 1954 | ||

| Successor use | Jupiter II colliery | ||

| Funded raw materials | |||

| Degradation of | Hard coal | ||

| Geographical location | |||

| Coordinates | 51 ° 24 ′ 47.2 " N , 7 ° 18 ′ 56" E | ||

|

|||

| Location | Vormholz | ||

| local community | Witten | ||

| District ( NUTS3 ) | Ennepe-Ruhr district | ||

| country | State of North Rhine-Westphalia | ||

| Country | Germany | ||

| District | Ruhr area | ||

The Renate colliery is a former hard coal mine in the Witten district of Vormholz . The colliery was only in operation as a small mine for a few years, the owner of the small mine was Renate Bergbaugesellschaft mbH.

history

In 1950 the Renate colliery was put into operation. The mine field was in the area of the Muttental near the old Göpelschacht Juno. The shaft belonged to the former Fortuna colliery to the east . After commissioning has begun a tonnlägigen shaft to sink . The shaft was sunk with a dip of 77 gons southward. On June 21 of the same year there was a longwall / route break in which three miners were killed in an accident. In 1951, the tonnage shaft reached a shallow depth of 60 meters. The shaft was also used at times to extract coal from the Jupiter II colliery. After the seams of the Girondelle group had been reached, they were dismantled. Due to the coal shortage after the Second World War, seams were mined that were not worth building for the previous operation . In order to improve the ventilation , some haws were made up to days after . The resulting overburden was heaped up over days in the Muttental. On February 1, 1952, the miner's insurance began. On February 28, 1954, the Renate colliery was shut down, and the mining shaft, which took several tonnes, was then still used at times by the Jupiter II colliery.

Day facilities and alignment

Initially, a simple conveyor reel operated using compressed air was used as the conveyor system . The reel was used to convey small conveying vessels through the shaft on rails. As a headframe , a simple tripod served. Later a wooden headframe and a machine house were built. First, the barrel-length shaft was sunk into the deposit following the Finefrau seam . A crosscut was driven underground from the shaft . The cross passage was driven into the seams Girondelle 2 and 3 in order to then dismantle them. Due to the civil engineering it was necessary, the mine water and the penetrating leachate to Erbstollen pump up.

Promotion and workforce

The first known workforce and production figures come from 1950, at that time 17 miners were employed in the mine, who produced 13,007 tons. The maximum extraction was achieved in 1952 by 58 miners, 23,526 tons of hard coal were extracted, these are also the last known extraction and workforce figures for the mine.

Current condition

The reconstructed machine house, the wooden headframe and the conveyor vessel are still reminiscent of the Renate colliery. The shaft opening of the barrel-length shaft is also still there. The buildings are part of the mining circuit in Muttental .

Individual evidence

- ↑ a b c d e f g Joachim Huske : The coal mines in the Ruhr area. Data and facts from the beginning to 2005 (= publications from the German Mining Museum Bochum 144) 3rd revised and expanded edition. Self-published by the German Mining Museum, Bochum 2006, ISBN 3-937203-24-9 .

- ↑ a b c d e Gerhard Koetter (Ed.): From seams, tunnels and shafts in the Muttental. 1st edition, Klartext Verlag, Essen 2007, ISBN 978-3-89861-612-6 .

- ↑ a b c d Gerhard Koetter (Ed.): Mining in the Muttental. 1st edition, Druckstatt Wöhrle, Witten 2001, ISBN 3-00-008659-5 .

- ↑ Mining in Muttental (PDF; 31 kB) (accessed on May 8, 2014)

Web links

- Photo of the headframe (last accessed on May 8, 2014)