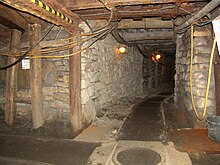

Cross passage

The cross-cut is a horizontal mine opening , which usually by a straightening path from right angles to the course a deposit ascended is and this only selectively unlocks . Due to the geological conditions - strike and collapse of the mountain strata that form the adjacent rock - a crosscut in coal mining runs at right angles to the strike of the adjacent rock. The cross passage has no direct connection to the surface, unlike the tunnel . Crosscuts are also used as a connection between two or more separate tubes of tunnels .

Basics

Shallowly sloping and massive deposits can be aligned starting from the shaft with fixtures . This is not possible with steeply dipping deposits; they must be aligned using cross cuts. Crosscuts are usually driven in the cross rock approximately at right angles to the strike direction of the deposit. In the case of the Gangerz, the crosscut is always based on the strike direction of the deposit and therefore has no relation to the strike of the adjacent rock. The distance and the location of the individual crosscuts depend on the local geological conditions. In Ruhr mining, the distance between the individual crosscuts in a mine varies from several hundred meters to 2.5 kilometers. In tonnlägigen shafts crosscuts are not usually required. However, if there are other parts of the deposit above or below, it is also necessary to drive cross-passages in tonnage shafts.

Subdivision of the cross passages

Depending on the size of the pit , a different number of cross-passages is required. In larger mines, several main crosscuts are driven from the shaft . In the individual construction departments, several departmental crosscuts are driven depending on the orientation. For ventilation are weather crosscuts ascended. In addition, there are swamp crosscuts , local crosscuts and pipe crosscuts . In seam-like deposits, the crosscuts go through the entire mountain body. With additional safety pillars to save, the cross passages are on the different soles in the same Seigerebene ascended.

Main crosscuts

Main crosscuts connect the filling point of the manhole with the respective straightening sections. Main crosscuts have the same tasks as the shaft and can therefore be regarded as the bottom continuation of the shaft. Since the main weather flows are led into the mine field through the main crosscuts, they must have a sufficiently large cross-section. To track promotion they are at least two lanes expanded. They are either led to the mine sheath or to the last seam worthy of construction . For water drainage will be in the range of impacts of water self- installed. They are only ascended with a very slight increase.

Departmental crosscuts

Departmental crosscuts divide the construction site into individual sections, which are called construction departments. These departmental crosscuts are used in particular in deposits with high rock pressure or heavily outgassing mountains. In hard coal mining in particular, it is necessary to divide the weather flow in order to minimize the accumulation of firedamp . In the case of steep storage, the departmental crosscuts enable neighboring seams in the respective department to be removed at the same time. Since departmental crosscuts only combine one seam group, they are usually shorter than main crosscuts. They are driven up with a slight increase of 1: 200. Since only partial ventilation flows go through a departmental cross-passage, the cross-section can be smaller than that of main cross-passages. The distance between the departmental crosscuts depends on the length of the respective construction departments.

Weather crosscuts

Weather crosscuts are driven in a mine field in order to enable the weather management of the individual companies. The weather crosscuts are usually located on the respective bottom of the mine. The downwash from the individual construction fields is channeled through the weather crosscuts . Weather crosscuts are either driven again or in the case of mines that have been in operation for a longer period of time, the earlier production crosscuts are used as weather crosscuts. Due to the degradation effects and the resulting convergence , weather crosscuts tend to merge strongly. So that a sufficiently large amount of weather can be guided through the weather crosscuts, these are repaired if necessary. To do this, the lying must be lowered and the defective route extension replaced. In most cases, the cross-section of the cross passage is also expanded. In the case of cross-passages with a short distance, the mining operations are aligned in such a way that construction lengths between three cross-passages are dismantled in order to extend the overall length. The middle cross passage serves as a weather cross passage. If the pit field is elongated in a crosscutting direction or if the shaft is located quite far on a field boundary, weather crosscuts are driven separately.

Other crosscuts

Swamp crosscuts serve, together with the swamp stretches, to form a route network beneath the deepest production floor. This route network serves to collect the pit water . By tube crosscuts the risers of be mine drainage pumps out. These crosscuts only have a small cross-section. In the case of steam-driven pumps, the steam lines were also led through the pipe cross-cut and the hot weather from the engine room was carried away. If several companies have to be connected to one another in the area of dismantling , these are connected with crosscuts. These local crosscuts are small crosscuts that are also used to connect to a jointly used brake shaft. Rising crosscuts are required for the brake mountain conveyance . These are cross-passages that are driven more or less at right angles against the layer falling.

Individual evidence

- ^ Walter Bischoff , Heinz Bramann, Westfälische Berggewerkschaftskasse Bochum: The small mining dictionary. 7th edition. Glückauf Verlag, Essen 1988, ISBN 3-7739-0501-7 .

- ^ Ernst-Ulrich Reuther: Textbook of mining science. First volume, 12th edition, VGE Verlag GmbH, Essen 2010, ISBN 978-3-86797-076-1 .

- ↑ Dimitrios Kolymbas: Geotechnical tunnel construction and tunnel mechanics . Springer Verlag, Berlin / Heidelberg / New York 1998, ISBN 3-540-62805-3 .

- ^ Emil Stöhr, Emil Treptow: Basics of mining science including processing. Spielhagen & Schurich publishing house, Vienna 1892.

- ^ Herbert Stahl (editor), Gerhard Geurts , Herbert Ommer : Das Erbe des Erzes. Volume 2. The pits in the Gangerz deposits in the Bensberg ore district . Cologne 2004, ISBN 3-00-014668-7 glossary.

- ↑ Ernst-Ulrich Reuther: Introduction to mining. 1st edition. Glückauf Verlag, Essen 1982, ISBN 3-7739-0390-1 .

- ^ A b Albert Serlo: Guide to mining science. First volume. Published by Julius Springer, Berlin 1884.

- ↑ a b c d e Fritz Heise, Fritz Herbst: Textbook of mining science with special consideration of hard coal mining. First volume. Published by Julius Springer, Berlin 1908.

- ^ A b c Carl Hellmut Fritzsche: Textbook of mining science. Second volume. 10th edition. Springer Verlag, Berlin / Göttingen / Heidelberg 1962.

- ^ Heinrich Veith: German mountain dictionary with evidence. Published by Wilhelm Gottlieb Korn, Breslau 1871.