Leaded glass window

Lead glass windows are windows in which the individual pieces of flat glass are framed by U- and H-shaped lead rods and soldered together along the edges. Before it was possible to produce larger glass surfaces, lattice and leaded glass windows were the only way to glaze larger wall openings. Today they are mostly realized as artistic works. Despite the similarity of names, lead glass is not used in leaded glass windows .

history

Lead glass windows have been common in Europe since the High Middle Ages . At first this technique was only used for the windows of the great cathedrals . Leaded glass windows are an important feature of the Gothic . From the end of the Middle Ages, however, more and more secular buildings were equipped with stained glass .

The process of assembling a larger glass surface from small pieces is based on the difficulty of cooling liquid glass in a larger area so that it does not crack. It was only with the production of real antique glass that larger glass surfaces became possible, and this problem was completely solved by flat glass. The only way for the glassmakers of the Middle Ages to do this was to produce small panes of glass and to connect and cement them using lead rods. By using differently colored pieces of glass, picture windows were created that transformed the apparent disadvantage into an art form of their own. The technically conditioned structure of the lead rods forms a special "graphic" design element. The shards were often worked with black solder and silver yellow in order to achieve fine contours, shadow effects and yellow spots.

The central part of a lead glass pane painted with glaze paints is known as the cabinet pane .

Lead glass windows are still made for sacred and profane buildings today.

technology

material

- Glass : Hand-blown glasses are, for example, real antique glass andreal antique flashed glass. New antique glass ,Goethe glass , cathedral glass, opalescent glass and Danziger glass are glasses made in the table-cast-roll process. Ornamental glass and float glass are made by machine using the drawing process. A special form are slug disks (moon disks) made using centrifugal technology. Antique glass isblown into a hollow cylinderwith a glassmaker's pipe , cut lengthways with red-hot iron, rolled up with a doctor blade, stretched and tempered in the oven. This creates a lively surface with streaks and bubbles; these are caused by the squeegee.

- Lead : The soft, malleable lead (lead rods) is ideal for connecting pieces of glass with one another, but is not very resilient as a load-bearing element and backbone of the glazing. The stability of the lead fields can be significantly increased by using steel inserts. Alternatively, galvanized flat steel tap wrenches can be soldered on. Lead rods about two meters long and in several widths are drawn from so-called broken lead, with different profiles and lead cores of different heights.

- Tin solder , solder: Tin solder consists of 60% tin and 40% lead. Its melting point is 100 ° C lower than that of lead, so that it is possible to connect two lead rods without the lead melting. Stearic oil, stearic wax and solder paste are used as solder.

- Putty : To make lead glass windows waterproof and more stable, the lead cheeks are coated with putty . Alternatively, a liquid is stirred paste of is linseed oil , chalk , carbon black and turpentine or mineral spirits painted on the inner side cheeks of the lead rod prior to insertion of the glass to seal the joints.

Tools

- Stencil scissors and stencil knives have double blades 1.5 mm apart. That corresponds to the thickness of the lead core. If you cut the stencils with normal scissors, they would be too big. Template scissors and knives cut a thin strip out of the cardboard, after which the glass is cut.

- The glass cutter with a steel wheel or a cutting diamond is available for cutting the glasses . The cutting carriage allows straight cuts to be made, and the circular cutter can be used to make circles.

- With the glass hammer or the metal handle of the glass cutter you can hit the cut from below after cutting, so that the glass can be separated more easily.

- Frying pliers and grinding stone are used to straighten irregular edges and remove the burr.

- The lead is cut into pieces with the lead knife and widened slightly with the lead reamer so that the panes can be pushed into the profile more easily. Glass nails fix the pieces of glass on the lead table.

- The soldering iron heats the solder that connects the lead rods.

- With the help of the putty knife or by means of a brush , the soft putty gets under the lead cheeks.

Work steps

The draft is usually created on a 1:10 scale. It is important to have clear lines appropriate to the material. Small areas and shapes that are difficult to cut are unfavorable. After the design drawing , the artist makes the cardboard box . In original size, he determines the lead lines, the thickness of the lead rods and the preliminary color scheme and marks the areas for etching or grinding work. The glazier determines the lead rungs in the lead crack, the edge lead being calculated according to the fold of the frame.

The lead crack forms the template for the stencils made of strong paper; they are numbered as the lead field can be inserted or numbered from top to bottom right. With the template scissors or a template knife, the glazier cuts along the lines and places the finished parts back on the design.

Now he selects the colored glasses and assigns them to the templates. He places it on a pane of glass to save space, cuts along the edge of the template with the glass cutter and breaks off the piece with his hands. Burrs or points are defused with a grinder or whetstone.

In contrast to this technique, it is possible to work without cardboard and templates. If the glass pieces are cut freely, the shape and color can be changed at any time. The exact outlines of the lead fields are drawn on large panes of carrier glass and the cutting lines of the glasses are sketched on them. The pieces of glass are cut together like a mosaic and adapted to the panes next to them. Through this free improvisation, constant checking and changing, one is not hindered by initial determinations. Josef Oberberger used this method of free cutting, for example, to design the windows in Augsburg Cathedral and Regensburg Cathedral .

After the glass cutting begins leaded . Two flat stop bars are nailed to the left and front at a right angle on a large lead table . The glazier first places two edge sheets or edge sheets on this. He pushes the first piece of glass into an edge lead and fixes it with a nail. A piece of inner lead is compressed and led to the glass so that it encloses the piece with one side of the H-shaped profile. Projecting ends are cut off sharply at the edge of the glass with a lead knife and then compressed by placing a lead knife underneath with a hammer. This work is continued until the end through the last two edge leads, after which the glazier fixes the window with wooden strips. Now he is on the joints of the pieces of lead some solder and sets with solder and a hot soldering iron a flat, sufficiently large soldering point . When all the lead rods are firmly connected in this way, he repeats the process on the back of the lead field. To make it more stable, putty can be added to the open lead profiles. These are then crossed off. The window is made particularly stiff by completely tinning the lead bars. Steel inserts or tap wrenches give additional strength.

Finally, clean the window with kerosene, whiting chalk or sawdust. If the picture is intended for hanging, loops of copper wire or lead are attached. Mostly, however, it is inserted into a folded frame made of wood, metal or stone. This technique is also used for stained glass , where the panes are painted with black solder and enamel paints and then fired before being leaded.

Conservation and restoration

In the event of glass breakage, weather-related damage or restoration of old glass windows, it is important to preserve the existing substance as much as possible. Jumps can be glued or secured with jump lead. The cleaning of soiled glasses must be done very gently so as not to damage any painting or the glass surface. Missing pieces of glass are replenished true to the original, as are destroyed parts of the lead mesh.

Famous artist

- see list of glass painters ; List of stained glass workshops

- Marc Chagall designed numerous stained glass windows for churches, synagogues and mosques.

- Wilhelm Buschulte

- Werner Persy

- Sergio de Castro

Examples

Strasbourg Cathedral : Emperor's window, 13th century (today in the women's shelter museum )

Lead glazing at the Angelika Kauffmann Museum in Schwarzenberg

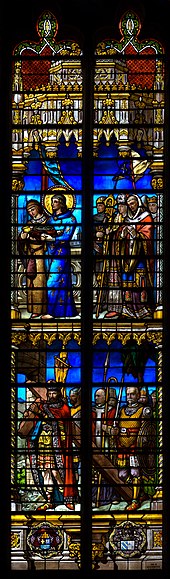

Stained glass window in the Munich City Hall

Largest church window north of the Alps in Altenberg Cathedral in Odenthal

Old Church Zurich - Wollishofen

Choir window of the village church Radewege

Sergio de Castro , stained glass window in the church of the Benedictine monastery in Couvrechef-la-Folie, Caen (1956–1958).

- The life of Jesus Christ, Chartres Cathedral (12th century)

Chromolithography 1868.

See also

literature

- Hans-Rainer Bernhardt and Guido Andelfinger: Working with colored glass. A manual for fine art glazing and stained glass. Kunstverlag Weingarten, Weingarten 2000, ISBN 3-8170-2034-1 .

- Claus Bernet : Church windows and glass work. Norderstedt 2013, ISBN 978-3-8482-5822-2 .

Web links

- Corpus Vitrearum Germany - Research Center for Medieval Glass Painting

- Internet presence of the Research Center for Glass Painting of the 20th Century eV with a list of artists and window images

- Christian Jakob: craftsmanship! How to make a church window , SWR Fernsehen - Landesschau Rheinland-Pfalz from December 14, 2018 (YouTube from July 17, 2018)

Individual evidence

- ^ Cabinet disc - The large art dictionary by PW Hartmann . Website beyars.com. Retrieved August 18, 2015.

- ↑ Description of the manufacture of leaded glass windows on the website of the Steel Window Company .