Coordinate measuring technology

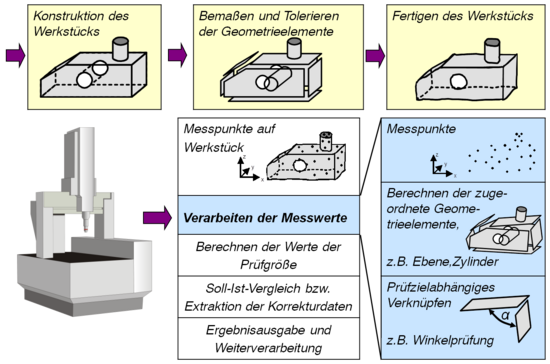

The Coordinate Metrology is part of the production measurement . A coordinate measuring system , also known as a coordinate measuring machine (CMM), is used to record spatial coordinates of points on a workpiece surface. These measuring points are processed further with a computer and the values of the selected, assigned, geometric variables (e.g. length, distance, angle) are calculated.

Principle of coordinate measuring technology

By using coordinate measuring systems, it is possible to check whether workpieces correspond to the designer's specifications with regard to their geometric shape . The shape of workpieces is described by standard geometric elements (e.g. point , straight line , circle , plane , sphere , cylinder , cone , torus ), regular shape surfaces (e.g. thread , toothing ) or freeform surfaces , the position and orientation of which is dimensioned by the designer and are tolerated (e.g. according to the rules of the "Geometric Product Specification and Verification" GPS).

In the preparation phase of the measurement, the geometrical elements required to record the features to be checked and the necessary number and distribution of the contact points on the surface of the workpiece are determined.

When the measurement is carried out, the coordinate values of the contact points ( measuring points ) are recorded in a coordinate system specified by the device by a coordinate measuring system. From this, the considered geometric elements are determined in a computer, which describe the surface of the real workpiece in an idealized form (filtering and assignment). In addition to standard geometry elements, other surface geometries such as threads, toothing or free-form surfaces can also be recorded and described mathematically. Further operations are used to determine relationships between several geometric elements such as B. angles (e.g. between two planes), distances (e.g. between two hole axes) or creates new ideal geometry elements (e.g. intersection of two planes).

All defined coordinate values initially relate to the device coordinate system of the coordinate measuring system. This is a coordinate system specified by the device manufacturer, which, depending on the design, is mostly parallel to the orthogonal movement axes of the coordinate measuring system. In order to be able to carry out a comparison of the actual values with the required structural specifications ( setpoint values ), however, coordinate values that relate to the workpiece are required. Therefore, after the measurement, all coordinate values are transformed into a workpiece coordinate system , which is defined by the operator prior to the measurement according to the specifications of the technical drawing using different alignment methods (e.g. 3-2-1 method).

The principle of point-by-point acquisition and the flexible variation of the recorded points - adapted to the respective measuring situation - gives the coordinate measuring machine its great universality. This also enables complex measurement tasks to be solved, such as the determination of deviations in non-embodied geometric elements (e.g. angular deviations of a bore axis, cutting edges of hob cutters ).

Basics of coordinate measuring technology

switching systems

This is the simpler and cheaper type. These touch probes can only determine the material contact by deflecting the stylus. The coordinates of the center of the sphere are determined at the moment of deflection. The probe must move back for the next touch. Only after the button is closed again can it be touched again. This method is sufficient for conventional measurements. You can also scan with these buttons, but when recording a large number of points, the required travel to and from the site takes a lot of time.

measuring systems

These touch probes are significantly more expensive, but also much more accurate and can be used universally. A small measuring machine is located in the probe head. Not only is a signal generated for material contact, but the deflection of the stylus is measured. The machine control can use these measured values to determine the exact coordinates of the probe ball center. The stylus ball can stay in contact with the material, the control is able to move along the workpiece with constant contact force and continuously record data. This process is predestined for scanning. Scanning is faster and more accurate with these probing systems. In addition, self-centering probes are only possible with these systems. This is necessary to determine tooth gaps or grooves.

Application areas of coordinate measuring technology

Due to their principle of point-by-point or section-by-section, linear or areal detection of the surface and the computational linking of the measuring points, coordinate measuring systems can be used very universally for measuring tasks with regard to dimension, angle, position and shape measurement of standard geometric elements and freeform surfaces. The range of measurable parts is diverse (e.g. housings, gears, optical components, molded parts).

With coordinate measuring machines, parameters of standard geometry elements and free-form surfaces can be determined in accordance with standards for

- Dimensions , distances and angles ,

- Positional relationships and

- Shape deviations ( shape deviations 1st order).

Measurements on workpieces are carried out for three important purposes:

- Conformity check (shape control)

- Measurements of the first cut workpiece to adjust the manufacturing process ( sampling )

- Monitoring and, if necessary, correction of the manufacturing process.

In addition, measurements are carried out on tools to determine form deviations and special function-oriented tests are also possible, such as

- Gauge simulation (simulation of pairings),

- Measurement of gears (determination of the module ),

- Wear measurement (e.g. wear of a turbine blade),

- Testing of special functions (e.g. the stroke of a ram on a guideway).

Coordinate measuring systems are used for quality assurance in many branches of industry, but mainly in mechanical engineering. In contrast to conventional measuring technology (manual measuring equipment, multi-point measuring systems), the main advantages are universality, flexibility and good measuring accuracy (fine resolution , small measurement deviations and low measurement uncertainty ). Many measuring tasks can only be solved with coordinate measuring technology, which is why quality assurance in some branches of industry without coordinate measuring systems has become unthinkable.

Device technology

Evaluation of measured coordinate values

Evaluation means: compressing the coordinates of the probed points into feature-related statements about the recorded shape of the workpiece. In data preprocessing, the device and temperature-related systematic measurement deviations - possibly also the probe system-specific - are largely corrected mathematically and, if necessary, the stylus bending caused by the probe forces is corrected. In the evaluation, the parameters of the substitute elements for location, orientation, dimension and form deviations with or without secondary conditions with function-oriented selected evaluation criteria are calculated from the coordinates of the measuring points. Further information on this is given in, and.

Demarcation

Coordinate metrology should not be confused with form metrology , in which individual measuring points are also recorded, but only deviations from a given ideal shape (mostly straight lines, circles or cylinders) can be determined.

Surface metrology (e.g. profile method ) is also to be seen as a separate area, since only lateral and vertical differences between linear or area-based measuring points are evaluated here. There is no reference to a device coordinate system or workpiece coordinate system in this case. The focus is on the determination of shape deviations of the 2nd to 5th order (waviness parameters and roughness parameters of a surface) using standardized filter and evaluation algorithms.

VDI / VDE GMA technical committee 3.31 coordinate measuring machines

Current questions in the field of coordinate measuring technology are dealt with by the VDI / VDE-Gesellschaft Mess- und Automatisierungstechnik (GMA) Technical Committee (FA) "3.31 Coordinate Measuring Machines".

Standards and guidelines relating to coordinate metrology

- DIN EN ISO 10360 series: Geometrical product specifications (GPS) - acceptance test and confirmation test for coordinate measuring machines (CMM). An overview is given on the ISO / TC13 homepage.

- VDI / VDE 2617 series: Accuracy of coordinate measuring machines - parameters and their testing. An overview is given on the GMA FA homepage “3.31 Coordinate Measuring Machines”.

literature

- Albert Weckenmann (Ed.): Coordinate measuring technology: Flexible strategies for functional and production-oriented testing. 2nd Edition. Hanser, 2012.

- Robert J. Hocken, Paulo H. Pereira (Eds.): Coordinate Measuring Machines and Systems (Manufacturing, Engineering and Materials Processing) . CRC Press, 2011.

- Wolfgang Dutschke, Claus P. Keferstein: Production metrology: Practice-oriented principles, modern measuring methods. 5th edition. Vieweg + Teubner, 2005.

- Ralf Christoph, Hans J. Neumann: Multi-sensor coordinate measuring technology - production-related, optical-tactile measurement, shape and position determination . (= The Library of Technology. Volume 248). Verlag Moderne Industrie, 2006.

Web links

- Coordinate measuring technology training - AUKOM - E-learning system AUKOM level 1 ( Memento from November 12, 2013 in the web archive archive.today )

- European training concept for Coordinate Metrology - EUKOM

- http://www.koordinatenmesstechnik.de/

Individual evidence

- ↑ a b DIN EN ISO 8015: Geometrical Product Specifications (GPS) - Basics - Concepts, principles and rules, 2011.

- ↑ Measuring with the coordinate measuring machine - 3-2-1 alignment. ( Memento from November 12, 2013 in the web archive archive.today )

- ↑ a b c Albert Weckenmann, Bernd Gawande: Coordinate measuring technology - basic principles, device technology, extensions for coordinate measuring machines . QZ-online.

- ↑ Evaluation of measurement - overview. ( Memento from November 12, 2013 in the web archive archive.today )

- ↑ coordinatenmesstechnik.de

- ↑ vdi.de

- ↑ iso.org

- ↑ vdi.de