zipper

The zip fastener (also called zip fastener or Zipp / Zip for short ) is a fastener for textiles , leather or foils that can be loosened any number of times and is based on a form fit . It consists of two side parts with staples (small teeth) and a slider (Swiss German: slide) with which the staples can be hooked together and released again. Zippers can now be made inexpensively not only from metal , but also from plastic . There are also waterproof and airtight (gas-tight) zippers. In the area of clothing and leather goods, design-oriented zippers are mainly used. In technically demanding applications, such as in the fields of medicine, technology, the military, and the outdoors, it is mainly the waterproof and airtight zippers that are required.

construction

Each strip has fine metal teeth, made of brass , nickel silver or aluminum , which are hooked into each other when closed by a slide. In modern zip fasteners, plastic teeth (mostly made of polyoxymethylene ) are used more and more , which are injected onto the fabric strips in an injection molding process . Zippers with a plastic spiral are also common.

Zippers are essentially classified according to the following different types:

- closed zippers

- Zippers open on one side

- divisible zippers

A special form of the divisible zipper is the two-way zipper, which can be opened or closed at both ends. All divisible zippers must be operated carefully.

Spiral zip

Of the two coils (or helices ) of a spiral zipper, one is coiled to the right and one to the left so that they fit together well. The helix pitches are also reduced in the overlap area and increased where they are woven into the textile tape. The spirals get stuck because the two oval helices are most curved where they penetrate each other and exactly there at the loop tip the plastic wire widens by about 50% (in the direction of the zipper), forming a double T-hook. Alternately, two loops of one helix hold the T-hook extensions of one loop tip of the other helix and vice versa. This type of hooking achieves good cohesion with great flexibility of the zipper.

Since the section through the plastic wire does not show a cavity, the hook-shaped thickening is achieved by squeezing the wire crosswise. The helix loop also kinks a little here, so it curves more strongly.

The individual parts of a zipper are:

|

history

Before the zipper could start its triumphant advance, items of clothing were held together with cords , ribbons, ribbon ties , fibulae , toggles and buttons as well as hooks and eyes.

The zipper was developed by several inventors starting in 1851 . The automatic, uninterrupted clothes fastener patented by Elias Howe in 1851 has not yet found practical use. The first practicable idea for this came from the American Whitcomb Judson from Chicago in 1890; he applied for a patent for them in 1892 and 1893 (“ clasp locker ”, “clamp opener for shoes”). It was used here to open and close the boots. In the same year the zipper was presented by its inventor at the world exhibition in Chicago . Here, however, it was unable to arouse the interest of potential users or the general specialist audience. He then founded a company with Colonel Lewis Walker (1855–1938) to develop the patent further and to design possible manufacturing machines for it. In 1905 a production machine was built, but the result was still far from being used in practice. Disappointed with the result, Judson gave up and left the Automatic Hook and Eye Company to Walker .

It was not until 1912 that the Swede, Gideon Sundbäck, satisfied customers thanks to a few improvements, after he had patented his ideas in Germany for the first time in 1909. In 1923, Martin Othmar Winterhalter from St. Gallen ( Switzerland ) acquired the European patent , further developed the closure, which originally consisted of beads and clamping jaws, and replaced it with the ribs and grooves that are still used today. He gave the product the name RiRi (= gutter rib). In his company Riri in Wuppertal (later and to this day in Mendrisio ) the world's first mass-produced zipper was produced.

Zippers were first used on a large scale in 1917 in the US Navy in weatherproof suits for pilots . The general implementation in everyday clothing took place from 1925 and 1935. Since then, zippers have replaced buttons in many places in the textile sector .

Since the mid-1950s, plastic zippers became increasingly popular. These are significantly more flexible and have a higher strength than metal zippers.

In Germany alone, around 70 million running meters of zippers are produced every year. The world's largest producer of zippers is the Japanese company Yoshida Kōgyō (YKK).

maintenance

Zippers that are exposed to the weather, for example in shoes , boots or tents , should be regularly cleaned of sand, dirt and other foreign objects and then treated with silicone spray. As a result, the zipper remains smooth and the service life is significantly extended; because dirt particles in the zipper increase its wear and tear. In addition, a silicone-based impregnation of the zipper causes the tape to be sealed and, in part, prevents water from penetrating through the teeth or coil. The use of waterproof zippers is recommended for applications with special requirements in terms of waterproofness. With regard to the integration and maintenance of the waterproof zippers, however, there are special requirements in contrast to conventional fashion-oriented zippers.

Stiff zippers with metal staples can be made more common by rubbing them with soap , wax or graphite . In the case of zippers with plastic teeth or plastic spirals, silicone spray helps to make them run smoothly again. If you make sure to always close zippers with plastic spirals when washing, they will not become stiff in the first place. Metallic ones should also be closed so that they do not unnecessarily rub off the laundry.

Weak points and repair

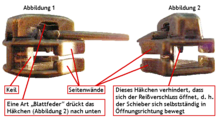

A weak point of zippers is the slide (zipper, slide) on the wedge connection. If an unkempt / unlubricated zipper is sluggish, the pull on the slider can become so great that it breaks (possibly also due to a fatigue break ). In the meantime, replacement zippers are also available here, which can be attached to the zipper at a later date. Another problem with zippers is the manageability of the slide, which is difficult to grasp for children, people with restricted motor skills or when using them with gloves. This can be done by increasing the area, e.g. B. by means of attached straps or loops are facilitated.

variants

- Variants of zippers

Toothless zipper on a slide lock bag

Zipper process

The zipper process , with which two columns of vehicles are brought together in one lane, was named after the functional principle .

literature

- Jan Kedves: Ziiiiiiip . In: Süddeutsche Zeitung from 18./19. March 2017, p. 59.

- Charles Panati : Universal history of quite ordinary things (original title: Extraordinary Origins of Everyday Things , translated by Udo Rennert and Doris Mendlewitsch), Eichborn, Frankfurt am Main 1994, ISBN 3-8218-4118-4 (= Die Other Bibliothek . Volume 118) .

- Henry Petroski: Knife, fork, zipper: The evolution of everyday objects (original title: The Evolution of Useful Things , translated by Inge Rau). Birkhäuser, Basel 1994, ISBN 3-7643-2914-9 .

Web links

- The Zipper Story The history of the zipper. (Ririmayer CH)

- The original 1917 Sundback patent for the "Separable Fastener" (Engl.)

- The zipper - the historical development (Coats Opti)

Individual evidence

- ↑ Patent US504037 : Shoe-fastening. Filed August 17, 1892 , published July 29, 1893 , Applicant: Whitcomb Judson.

- ↑ Patent US504038 : Clasp locker or unlocker for shoes. Filed November 7, 1891 , published August 29, 1893 , Applicant: Whitcomb Judson.

- ↑ Patent DE216807 : Closure for items of clothing of all kinds and for everyday objects, consisting of eye and hook links arranged in a chain-like manner on the closure edges of the item of clothing or the like. Filed April 1, 1909 , published December 4, 1909 , Applicant: Gideon Sundback.

- ↑ Martin Othmar Winterhalter as the inventor of the zip fastener in www.tagblatt.ch, accessed on July 22, 2009