Type 93 torpedo

| Type 93 torpedo | |

|---|---|

|

|

|

| General Information | |

| Designation: | 九三 式 魚雷 |

| Country of origin: | Japan |

| Manufacturer: | Imperial Japanese Navy |

| Working time: | 1936 to 9/1945 |

| Technical specifications | |

| Length: | 9.0 meters |

| Diameter: | 610 millimeters |

| Combat weight: | 2700 kilograms |

| Drive: | Steam gas with oxygen as the compressed gas |

| Speed: | 48-50 knots |

| Range: | 40,000 meters |

| Furnishing | |

| Warhead: | 500 kilograms highly explosive |

| Target location: | no |

| Lists on the subject | |

The Type 93 torpedo ( Japanese 九三 式 魚雷 , kyūsan-shiki gyorai ) was a 610 mm torpedo that was used on warships of the Imperial Japanese Navy between 1936 and 1945. The designation Type 93 indicates the year of the first development, the year Kōki 2593 or 1933 according to the Gregorian calendar . Developed in strict secrecy, it became known in the western world as the Long-Lance Torpedo , given to it by the American naval historian Samuel Eliot Morison . It was both the longest range torpedo and the one with the largest warhead used in World War II . The technology of the Type 93 was the basis for other Japanese torpedoes and further developments such as the Kaiten .

Development history

Since 1883 the Japanese navy has been buying torpedoes from Europe, mainly from the manufacturers Whitehead and Schwartzkopff . The torpedoes were named in Japan after a naval naming system.

As early as 1916, the Japanese Navy carried out brief experiments with gas generators for torpedoes, which produced pure oxygen. However, the deflagration of the gas generators could not be adequately controlled. During the development of the Torpedo Type 6 (1917) and Torpedo Type 8 (1919), the technical knowledge from 1916 was used. In addition, the last German construction from the First World War , the 60 cm H torpedo, was extensively examined by the Japanese .

In 1924 eventually was Whitehead torpedo of the type Mark VIII procured by the Japanese Navy, were ordered by the 20 at the Whitehead plants in Weymouth and produced. In 1927, Shizuo Oyagi (later admiral of the Japanese Navy) received detailed information on the state of torpedo technology. There was particular interest in the oxygen enrichment of the propellant gases, which were temporarily used in the torpedoes "21 inch Mark VII" and "Mark VIII". Unlike the four-cylinder radial engine of the Mark VIII , the engine of the new Type 93 torpedo was supposed to be based on an earlier design of the Whitehead engines. This engine is a combination of a free piston engine and a reciprocating engine with two parallel cylinders and seawater cooling, which goes back to a development by Jones of the Whitehead shipyard in Fiume.

The Type 93 torpedo was developed for series production from 1928 by Captain Kishimoto Kaneharu and a working group of the Navy in Kure and was used on a large scale on surface ships of the Japanese Navy from 1936. The first pre-production model was the Type-93 Model 1 , which was completed in 1933. After a successful series of tests, the pre-series model was modified. The new version Type-93 Model 1 Mod. 1 had a pressure hull reinforced with ribs and enlarged seawater inlets to cool cylinder heads and connecting rods more effectively.

The variant that ultimately went into series production between 1936 and 1944 was an improved version of this "Modification 1".

- Type-93 Model 1 Mod. 2 received more reliable oxygen valves than the prototypes, reinforced frames and a simplified lubricating oil feed line for the engine. It was the most frequently produced version of the Type 93.

- Type-93 Model 2 was an experimental vehicle to adapt the torpedo to the maximum speeds of the Japanese destroyers who were supposed to use it by increasing the weapon’s own speed. The torpedo reached 52 knots but was never used. Only two pieces were built.

- Type-93 Model 3 was developed in 1943. Before take-off, the oxygen was not mixed with compressed air but with carbon tetrachloride and the warhead received a charge of 750 kg of explosives. However, the range was reduced to 30,000 meters.

The production facilities for the Type 93 were in Kure and Sasebo . The production numbers peaked in 1943.

Structure and functionality

Oxygen tanks

The torpedo basically followed the classic structure of already known torpedo types. Only the compressed air otherwise used was replaced by 98% pure oxygen . This led to a significantly higher energy yield, since the proportion of oxygen in air is only about 21%.

The internal structure of the weapon had to be changed, however, in order to counteract the risk of explosion from the oxygen in the 3.5 m long, 980 liter tank. So you positioned the tank immediately behind the warhead in the front part of the torpedo and removed it in this way as far as possible from the combustion chamber. The mechanisms and tanks that were needed for depth control and side steering were also built behind the tank, which further increased the distance to the combustion chamber. In addition, the oxygen tank, which was under 22,800 kPa (228 bar ) pressure, and the 95-liter fuel tank behind it, were shielded from the rear of the weapon by an intermediate bulkhead.

All lines that transported oxygen were carefully chemically cleaned before they were installed and laid in the upper part of the torpedo body in order to prevent the oxygen from reacting with liquids or contaminants. The problem of a violent, difficult-to-control reaction of the oxygen when the combustion chamber was ignited for the first time, on which the tests of other navies had failed, was solved by first filling the chamber with less dangerous compressed air and then slowly increasing the oxygen content until the maximum output was achieved.

Generator, motor and shaft

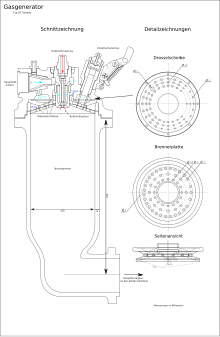

Gas generator

The gas generator with its combustion chamber was connected upstream of the cylinders and had the task of mixing and burning the fuels used. It had to be ensured that the generator was continuously fed constant amounts of fuel in order to guarantee a constant output.

- Oxygen from the main tank therefore first had to be fed into a small, upstream tank, in which a constant pressure was maintained in order to compensate for the falling pressure in the oxygen storage tank before it could be delivered to the generator.

- The fuel, which the Japanese called "number 1 petroleum ", on the other hand, was taken from the top of the fuel tank and used petroleum was replaced by water via a valve so that the level in the tank always remained the same and enough fuel always reached the separator in the tank . So the weight of the weapon remained unchanged.

When designing the gas generator, the Japanese engineers ran into a dilemma : on the one hand, they had to generate the hot gases possible in the combustion chamber and convey them to the cylinders; on the other hand, they had to prevent the heat in the chamber from reaching parts of the generator head Brought melting. They decided to use a pump to feed seawater into the combustion chamber as a coolant. The water had to evaporate completely in order to prevent the entire engine from losing power.

The processes in the generator began with the introduction of "number 1 petroleum" in the middle of the generator head, where it met the injected oxygen at right angles above the combustion chamber, which swirled the petroleum. In a similar way to the petroleum, the salt water was introduced into the generator as a coolant and solvent . The oxygen-petroleum-water mixture met in the combustion chamber of the generator, was ignited by a burner and burned to hot gas, whereby the volume of the mixture increased considerably and the pressure rose accordingly. The burning mixture heated the generator to 659 ° Celsius and was pressed into the supply lines of the two cylinders, which were located below the combustion chamber.

Motor and shaft

The hot gases were then fed under pressure into the two cylinders, which were driven in this way. As a result of the salt water used, the cylinders had to be lengthened by 3 mm so that the resulting salt water residues did not affect the top dead center of the pistons.

The engine was modified from a Whitehead torpedo , a two-cylinder piston engine from Great Britain , with which the achievable output was increased from 320 to 520 hp. This meant an increase in displacement compared to other contemporary torpedo types such as the British Mk VIII to more than double (around 11,208 cm³ compared to 4,588 cm³). At 350 kg, the engine weight of the Japanese Type 93 was 233 kg greater than that of the British torpedo.

The engine consisted of two cylinders arranged in parallel, which transmitted their power to the crankshaft with two connecting rods. The crankshaft and the gearbox formed a unit that transmitted the power to two opposing shafts with corresponding propellers. The motor principle was applied for as a drive motor with reversing gear for torpedoes by Frank William Dodd as an engineer of the Withehead torpedo works in Weymouth in 1909 for a patent.

The two cylinders of the engine drove a shaft with an output of 520 hp , which delivered its energy at up to 1200 revolutions per minute via an inner and outer shaft to two coaxially mounted, counter-rotating, four- blade propellers at the stern of the torpedo. The engine housing and the shaft in the aft torpedo section were bathed in sea water, so that a certain degree of cooling was achieved.

control

Depth control was taken over by a depth gauge which steered the horizontal rudders of the torpedo to maintain the preset depth. Directional control was carried out using a gyroscope that regulated the vertical rudders at the stern in order to steer the torpedo on the previously set course. The oars were based on the usual Whoolwich design. The energy that was needed for the rudder movements required to change direction and depth came from two tanks, in other variants from three tanks filled with compressed air. This compressed air operated the gyroscope and the servomotor of the rudder control.

Warhead and nose

The warhead consisted of 500 kg of explosives, which was housed in the front part of the torpedo. The Type 97 explosive used was a mixture of 60 parts TNT and 40 parts HNDA . The explosive charge was ignited by a conventional impact fuse after the Japanese had given up research on magnetos . The Type 90 and the Type 2 impact fuze introduced in 1940 differed from the Type 2 by a revised mechanism . The Type 90 was too sensitive to premature ignitions from the vibrations of the torpedo motor. In the case of type 2 , the distance after which the detonator was armed could also be set before the weapon was started.

Depending on the shape of the torpedo nose, the speed varied by two knots between the early Type 93 models and those produced from 1940.

commitment

Preparation and theoretical process

At regular intervals the torpedoes in service were dismantled and thoroughly cleaned of dirt and especially of oil residues in order to prevent dangerous chemical reactions that could lead to the weapon exploding.

When a torpedo mission was imminent, the "Type 93 torpedo" was refueled with oxygen by the operating crews. The oxygen required for this was generated on board the ships and pressed into the tank via a valve on the top of the torpedo.

When a target was recognized, the torpedo was programmed with the desired target range and the desired heading of the weapon using two dials on the top of the cylindrical weapon body.

The weapon was finally started by ejecting it from a torpedo tube , as it was usually set up in sets of twins, triplets or four on the deck of cruisers or destroyers . Shortly before the torpedo was ejected, the crew opened the compressed air shut-off valve and unlocked the oxygen check valve on the top of the torpedo. Pressing the launch lever on the torpedo tube released the safety device in the group valve and allowed the compressed air to start the generator and the pump in the torpedo and start the engine. When submerged in the water, a small flap on the torpedo body was folded over by the flowing water, thus releasing the compressed air in the control circuit, which operated the gyroscope and the servo motor for the rudder movements.

The torpedo motor was started up and brought up to the power that was necessary to reach the previously set target range. For very distant targets, the oxygen was burned slowly and the torpedo had a correspondingly lower speed - for example 38 knots at a distance of 40 kilometers from the target. At a short distance from the target, the weapon could accelerate to a top speed of almost 50 knots, but had exhausted its fuel after only 20 kilometers. The consumption of oxygen at such a high speed was 0.289 kg per second and that of fuel was 0.103 kg per second.

A major advantage occurred as a side effect of pure oxygen: the oxidizer reacted almost completely with the fuel to form water and carbon dioxide. These exhaust gases from the torpedo almost completely dissolved on their way in the sea water. In the torpedoes used up to now, the nitrogen content of the compressed air used did not participate in the reaction and formed a telltale bubble trail or even a luminescent wave.

Calls

The "Type 93 torpedo" was used by warships of the Imperial Japanese Navy during the entire Pacific War. The missions, with which the Allies were inflicted the greatest damage, were limited to the initial phase of the war between late 1941 and mid-1943. In the naval battles during this period, the imperial navy was able to and had its superior training in battles in the dark not yet lost control of the air to the United States Navy .

In February 1942, a fleet of the Imperial Navy, assigned to escort protection, provided a fleet of Allied cruisers and destroyers during the battle in the Java Sea . The Dutch cruisers Java , De Ruyter and the destroyer Kortenaer were sunk by "Type 93 torpedoes". Shortly afterwards, the two cruisers Perth and Houston also fell victim to “Type 93 torpedoes” in Sunda Strait . The British cruiser Exeter was arrested two days later and also sunk by a destroyer with a "Type 93 torpedo" after the British ship was immobilized after being hit by a shell.

Probably the most famous sinkings by "Type 93 torpedoes" took place during the naval battles around Guadalcanal. At the beginning of August 1942, a Japanese fleet penetrated into Ironbottom Sound under cover of darkness and surprised an Allied fleet there. The heavy cruisers Vincennes and Canberra were sunk by "Type 93 torpedoes" that damaged Chicago .

About a dozen other ships were sunk by Type 93 torpedoes in the later course of the war, the largest among them being the light cruiser Helena and the aircraft carrier Hornet , the latter having previously been abandoned by its crew.

On the Japanese side, the heavy cruisers Mikuma , Suzuya and Chōkai were lost when Type 93 torpedoes exploded on the ships due to enemy fire.

variants

- Type 94, Luftwaffe torpedo in two models with diameters of 533 mm and 610 mm, which never came into regular use

- Type 95 Model 1, submarine torpedo for 533 mm tubes with a reduced explosive charge of 405 kg

- Type 95 Model 2, submarine torpedo, 533 mm, with an explosive charge of 550 kg and reduced range

- Type 97 Model 1, torpedo for small submarines , 4500 meters range with 350 kg warhead, unusable due to a design flaw

- Type 98 (also known as "Type 97 Special"), from 1942 a torpedo for small submarines, Type 97 with a revised drive and control system

- Kaiten , manned suicide torpedo with Type 93 technology

Evidence and references

Individual evidence

- ↑ The chemical composition was described by the Americans after the war as follows: 86% C, 13% H, 1% S

literature

- Robert Gardiner: Warship 1991 . US Naval Institute Press, 1991, ISBN 1-55750-907-7 .

- Anthony Newpower, Frederick Praeger: Iron men and tin fish: the race to build a better torpedo during World War II . 2006, ISBN 0-275-99032-X .

Web links

- Japanese torpedoes at navweaps.com (English)

- Treatise on the Type 93 on a private website (Japanese)

Individual evidence

- ↑ a b c REPORTS OF THE US NAVAL TECHNICAL MISSION TO JAPAN 1945–1946, SERIES O: ORDNANCE TARGETS, JM-200-D, Japanese Torpedoes and Tubes-Article 1, Ship and Kaiten Torpedoes, April 8, 1946

- ↑ Nomenclature of torpedoes in the Japanese Navy Information on Torpedoes ( Memento from December 19, 2010 in the Internet Archive ) (accessed on February 20, 2011)

- ↑ Harald Fock: Z-before! International development and war missions of destroyers and torpedo boats. Volume 1, Koehlers Verlagsgesellschaft Hamburg 2001, ISBN 3-7822-0762-9 , page 20

- ^ Robert Gardiner Warship 1991 , Naval Institute Press, 1991, ISBN 978-1-55750-907-9

- ^ Biography Robert Whitehead (accessed February 20, 2011)

- ^ Patent specification "Improvements in and relating to Torpedoes", applicant: Whitehead & Co AG, Fiume, Hungary, GB191019353, (United Kingdom September 25, 1909 )

- ↑ Patent specification "Self-propelled torpedo with compressed air heating", inventor: Albert Edward Jones, GB 191111408 (United Kingdom May 11, 1911 ) DE 242130 (Germany May 3, 1910 )

- ↑ patent "Improvements in and Relating to Automobile Torpedoes", inventor: Frank William Dodd, GB 190902639 (United Kingdom July 30, 1909 )

- ↑ REPORTS OF THE US NAVAL TECHNICAL MISSION TO JAPAN 1945–1946, SERIES O: ORDNANCE TARGETS, JM-200-E, Japanese Explosives, page 8