DR series E 49

| Prussian EP 209/210 and EP 211/212 DR series E 49 |

|

|---|---|

|

E 49

|

|

| Numbering: | EP 209/210 and EP 211/212 DR E 49 00 (EP 211/212) |

| Number: | 2 double locomotives |

| Manufacturer: |

BEW (electrical part) LHW (mechanical part) |

| Year of construction (s): | 1913-1921 |

| Retirement: | 1925 EP 209/210 1929 EP 211/212 |

| Axis formula : | 2'B + B1 ' |

| Type : | 2'B + B1 'w2u |

| Gauge : | 1435 mm ( standard gauge ) |

| Length over buffers: | 16,493 mm |

| Total wheelbase: | 12,895 mm |

| Service mass: | 113.0 t |

| Friction mass: | 68.0 t |

| Top speed: | 90 km / h |

| Hourly output : | 1765 kW |

| Continuous output : | 1290 kW |

| Starting tractive effort: | 137 kN |

| Performance indicator: | 15.6 kW / t |

| Driving wheel diameter: | 1700 mm |

| Impeller diameter front: | 1100 mm |

| Rear wheel diameter: | 1150 mm |

| Power system : | 15 kV, 16 2 ⁄ 3 Hz ~ |

| Power transmission: | Overhead line |

| Number of traction motors: | 2 |

| Drive: | Back gear with coupling rod drive |

| Train brake: | Kbr m. Z. |

| Train heating: | Steam boiler |

The locomotives of the Prussian State Railways with the numbers EP 209/210 and EP 211/212 of the Wroclaw Railway Directorate were electric locomotives for express and passenger train service . At the Deutsche Reichsbahn the EP 211/212 received the number E 49 00 .

history

In 1911 Siemens-Schuckertwerke and Bergmann Elektrizitätswerke offered the Prussian State Railways various designs of express and passenger locomotives for their lines to be electrified. The Prussian State Railways ultimately decided on the project of a 2'D1 'locomotive (later EP 235 ) and double locomotives with a 2'B + B1' wheel arrangement. The plan was to procure 13 double locomotives, while only one of the 2'D1 'single-frame locomotives was ordered due to poor experience with the 1'D1' EG 501 locomotive . Since, contrary to all expectations, good test results were achieved with the EP 235 delivered in 1917, the remaining order for the double locomotives was canceled. Only two machines that were already in production were completed and put into service in 1921 as EP 209/210 and in 1922 as EP 211/212. Both vehicles fulfilled the required performance program, the transport of 500 t express trains horizontally at 90 km / h, as well as 400 t express and 360 t passenger trains with a 20 ‰ gradient without a leader locomotive in the same time as a steam locomotive, without any problems . Nevertheless, the locomotives were not satisfactory. The running characteristics were poor, especially when driving with the running axle ahead. Due to the shorter length of the 1'B vehicle part, there were swaying movements. The subsequent installation of a cardan-guided cross coupling did not help either. In addition, there was the poor quality of the locomotives due to the war . Both locomotives were mainly used on the Silesian mountain routes. But already after four years the EP 209/210 was taken out of service and taken out of service. The EP 211/212 was implemented in Magdeburg in 1926 . After suffering bearing damage on one of their engines, it was retired in 1929.

technical features

Mechanical part

The locomotives were built in two parts with the 2'B + B1 ' wheel arrangement. The larger part of the vehicle had a two-axle bogie and two coupling axles, while the smaller locomotive half had a Bissel frame in addition to the two coupling axles . The running gear was originally intended to be designed symmetrically, but the mass of the main transformer, as with the EP 235 , required the installation of an additional running axle. Both halves of the vehicle were driven by one motor each via a countershaft with a straight-toothed gearbox and a jackshaft via connecting rods on the coupling axles. The main frame of both locomotive halves was an inner frame made of 25 mm thick sheet steel, which was stiffened by the cast steel tub for the traction motor and the jackshaft, as well as other struts. Both frames were connected to one another by main and auxiliary coupling bars.

The respective locomotive body was made up of a steel profile frame and a sheet steel casing in the area of the engine rooms. The driver's cabs were wooden frames with sheet metal cladding. There were two engine room corridors per half of the locomotive. The locomotive boxes were connected to one another by a bellows and a transition bridge. The porch above the Bissel axis had two half-height water tanks for steam heating on the sides.

The braking device consisted of a single- release compressed air brake with an additional brake Kbr m. Z., air compressor and main air tank. The compressed air brake worked on one side of the coupling and running axles of each half of the locomotive. A throw lever handbrake acting on the same brake rod was available as a parking brake.

As auxiliary equipment, the locomotives had a coal-fired steam boiler with an induced draft fan for train heating. The coal was fed from the 700 kg storage container to the furnace via a manually operated drive roller. Both locomotives were equipped with signal whistles and sand spreading devices.

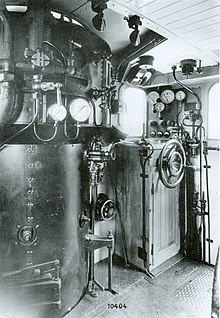

Electrical part

On the roof of each half of the locomotive there was a BEW type pantograph with curved bars and bracket separators . The main oil switch in the high-voltage chamber was connected via the flexible roof line between the vehicle parts . Furthermore, there was an overvoltage protection reactor and a current transformer in the high-voltage chamber .

In the front of the 2'B-half stood an externally ventilated dry-type transformer . The primary and secondary windings of both transformers were arranged separately. The secondary side had 16 taps for the traction motors. An auxiliary transformer for the control and the auxiliaries was also available.

It was controlled via electro-pneumatic contactors. Eleven continuous speed levels could be selected. Because of the high current consumption of the motors of ten kilo-amperes , six contactors were always energized for each speed step. The shooters were controlled by hand-operated roller switches. In order to be able to increase the engine speed, the brushes had to be adjusted after the last gear step. It was not possible to operate the contactor control and the brush adjustment at the same time.

The two traction motors were 14-pole alternating current series motors with external ventilation and compensation . They also had reversible poles . A special feature of the locomotives was the different engine types (EL 350 and EL 351). The reason for this was the mirror-image arrangement of the brush adjustment. A 16 V AC voltage supply fed by the auxiliary transformer was used to illuminate the locomotive.

Web links

literature

- Dieter Bäzold, Günther Fiebig: Railway vehicle archive Part 4: Electric locomotive archive . 6th edition, Transpress Verlag, Berlin 1987; ISBN 3-344-00173-6 .

- Siegfried Bufe: Railways in Silesia . 3rd edition, Bufe-Fachbuch-Verlag, Egglham 2001; ISBN 3-922138-37-3 .

- Glanert / Borbe / Richter Reichsbahn electric locomotives in Silesia VGB-Verlag 2015, ISBN 978-3-8375-1509-1 .