Glass device

In laboratory technology, glass devices is the generic term for devices that are made of glass because of the special properties of the material . Because of the thermal shock resistance and high chemical resistance, glass appliances are mostly made of borosilicate glass . Thermally highly-stressed glass units - such as pyrolysis tubes - are often out of the relatively brittle glass Supremax prepared containing up to 680 ° C is usable. Bomb tubes are made from the more pressure-resistant Durobax glass . For the highest thermal loads (softening point over 1400 ° C) as well as in photochemistry , devices made of quartz glass are often used, which has a very high resistance to temperature changes due to its low thermal expansion coefficient (5.8 · 10 −7 K −1 ).

Apparatus

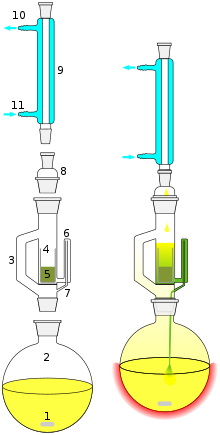

If several glass devices are connected to one another, one speaks of a glass apparatus. Large apparatus made of glass appliances with ground-joint connections are rigid, so a tension-free structure requires a lot of experience. Spherical joints that enable flexible apparatuses have proven themselves. These need a suitable clamp for fixation.

cut

In order to be able to build an airtight closed apparatus from glass devices, they usually have a glass cut at the connection points , which is why they are also referred to as ground glass devices. The most common type of cut is the conical cut in sizes NS 14.5, 29 or 45 ("NS" stands for " Normschliff ", the number behind it indicates the diameter in mm). The conical joint consists of a sleeve (the jacket joint) and the core (core joint). During assembly, the ground joint is greased with a medium- viscosity silicone paste (when working in a high vacuum, with a high-viscosity one). This creates an airtight seal and makes it easier to open later. The two connected parts are then fixed with a joint clamp ( joint clamp).

Further cuts are the plane cut (with the desiccator ), the cylindrical cut (with the KPG stirrer ) and the spherical cut.

Advantages of glass

- Resistance to most chemicals

- transparency

- Thermal deformability during production (can be brought into almost any shape by the glassblower by heating)

- Relatively insensitive to temperature changes due to the low thermal expansion coefficient

- Low price

- Easy to clean

Important glass equipment

Web links

Individual evidence

- ↑ a b Association of authors: Organikum . 19th edition, Johann Ambrosius Barth, Leipzig · Berlin · Heidelberg 1993, p. 1, ISBN 3-335-00343-8 , p. 653.