Bautenberg mine

| Bautenberg | |||

|---|---|---|---|

| General information about the mine | |||

| Bautenberg mine around 1900 | |||

| Funding / total | 2.869 million tons of iron ore | ||

| Rare minerals | Antimonite , cerussite , galena | ||

| Information about the mining company | |||

| Employees | up to 500 | ||

| Start of operation | 1461 | ||

| End of operation | March 31, 1942 | ||

| Funded raw materials | |||

| Degradation of | Iron ore , zinc blende , lead ore | ||

| Greatest depth | 1,025.2 m | ||

| Geographical location | |||

| Coordinates | 50 ° 47 '47.4 " N , 8 ° 4' 30" E | ||

|

|||

| Location | Savages | ||

| local community | Wilnsdorf | ||

| District ( NUTS3 ) | Siegen-Wittgenstein | ||

| country | State of North Rhine-Westphalia | ||

| Country | Germany | ||

| District | Burbach mountain area | ||

The Bautenberg mine (also Baudenberg ) was an iron ore mine near Wilden (municipality of Wilnsdorf ) in the southern Siegerland . The mine was located on the 512.9 m high Bautenberg between Wilden, Zeppenfeld and Gilsbach and at over 1000 m was at the same time one of the deeper and especially since the industrial boom from 1862 one of the more important pits in the area.

Aisle means

The passage means the pit belong to a vein-line in the north of the pit Landeskrone to the south to Peter colliery enough. The ore veins of the Bautenberg extend over 700 m .

About 50 m west of the first machine shaft was the ore vein that ran out to the southeast, then the salt vein , which also ran slightly to the southeast and was wider there. The thickness of the corridors grew from above with 1–2 m thick brown iron stone with increasing depth to up to 12 m thick pure iron stone . The filling compound was supplemented with shiny and clay slate with quartz strings and chunks of spar. Excretions of lead and zinc ores set in between the courses . At the height of the deep tunnel (40 m above the valley floor) the passage area of the ore deposits was about 720 m², while in the depth (480 m) it increased to about 1600 m². The area of approx. 1000–1200 m² was retained by the passage area up to the 720 m level (16th level). Only with further depth did it slowly decrease (700 m² on the lower levels, 580 m² on the 970 m level).

To the east of the salt corridor was the Neue Hope corridor , which carried the Spateisenstein with copper pebbles, lead, zinc ores and occasionally also feather ore and nickel antimony , and behind it the lying corridor . It was up to 8 m thick in the upper depths, but decreased to 1.5 m with increasing depth. The hanging corridor followed to the south .

The wide Schöneberger Gang opened up 50–100 m to the south , the siderite thickness here was 1–4 m. In the upper depths the corridor was divided into two pieces. The Poppelszecher Gang was about 150 m south . It had a thickness of 1–3 m with a mineable length of 60–90 m. Brown iron ore and spate iron stone mixed with lead ore were carried. Below the 770-m- sole which took silicification of the passage strongly, 1020 m the length of the corridor was approximately 120 m with a thickness of up to 3 m, but heavily engineered with quartz and thus only little mineable .

Terrain and surface facilities

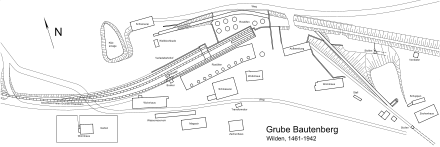

The pit pattern of the surface facilities was divided into three areas: the largest part in the Sterzenbachtal, about 600 m southeast of it and 700 m south of it. The first systems were in the Sterzenbachtal. In the last stand of the pit, there was the siding to the Freie Grunder Railway with a loading station in the middle of the facilities. To the south of it were several residential buildings, the locksmith's shop and, directly afterwards, part of the grate furnaces in the pit. To the north were further ovens, as well as the joinery and a sewage treatment plant . The ore was extracted from the tunnel east of the station. There was a processing facility and the beginning of a towing track that led to the old shaft that was started in 1869. This was about 600 m to the southeast, further up the slope of the Bautenberg. From there, another railway led south to the Neuen or Lorenzschacht, which was built in 1899. In addition to individual buildings that have survived to this day (residential buildings, colliery buildings) on the former mine site, the former director's villa can be found at the western exit of Wilden.

history

Age and importance

The history of mining in Siegerland goes back 2,500 years, but the Bautenberg mine was one of the older in the region. In 1461, the pit was first mentioned in an old appraisal register as "Budenberg". The ore was first extracted above ground through excavation and day shafts, later through the upper tunnel (at 418 m above sea level) and even later through the 600 m long Tiefen Bautenberger tunnel in the Wildens district (at 256 m above sea level). The tunnel brought a depth of 94 m underground and was 40 m above the Wildebach valley. In the 1840s he reached a middle course , in 1883 the Poppelszecher walk followed through a wing location .

In 1770 the Green Hope consolidation pit ( Lage ), in the field of which the first Bautenberger shaft was later sunk, was first mentioned. Iron, copper, lead and zinc ores were mined through a tunnel.

In 1804 the pit was one of the main pits in the Freie Grund. The Bautenberg was a good employer for the surrounding villages of Wilden , Gilsbach (zu Burbach ), Zeppenfeld and Wiederstein (both Neunkirchen ). 400 miners were employed there until the end.

Around 1900 the Phönix AG for mining and trade, Hoerde (later Duisburg) acquired the mine.

Industrialization and rail connection

From 1862 onwards, with increasing industrialization, ore extraction increased from 1,000 to almost 10,000 t per year within a few years (see table). In 1868 the construction of a narrow-gauge railway 6 km along the Rassberg ridge towards the train station in Neunkirchen began . Up until the same year, the mine was also called the Bautenberg Unity . This railway went into operation in 1873. In September 1878 the mine received a new locomotive.

The railway was replaced in 1907 by the new construction of the Free Grunder Railway , which led from Salchendorf through the valley to Wilden and in an arch to the pit on the Bautenberg. The arch was double-tracked so that the mine railways could bring the iron ore for further processing and at the same time drive it back to the mine. In 1897 209 people were employed at the Bautenberg.

Civil engineering

After the industrial boom , the first plans for civil engineering began in 1868 and a shaft was built in 1869 , which was used to mine from 1871.

The Green Hope Shaft (also known as the “Old Shaft”, location ) was built from 1871 and had a depth of 403.2 m, it was set at a height of 452.2 m above sea level. The shaft reached 130 m in 1883, 170 m in 1889, and 210 m in 1891. With the addition of mechanical drilling work in 1888 , the work was made so much easier that from now on we made great strides. The following levels on this shaft are known: 32 m, 62 m, 94 m, 130 m, 170 m, 210 m, 250 m, 300 m.

The Lorenzschacht (also "Neuer Schacht", Lage ) was sunk in 1899 and reached a depth of 720 m. It was set at 468.2 m above sea level and lay in the local area of Wiederstein . The shaft was sunk 600 m south of the old shaft because there were problems with this and civil engineering there was stopped. Today the 4 × 2.5 m Lorenzschacht has been filled , the remains are still visible. In 1900 a winding tower , a machine house and a boiler house as well as a 16 m high chimney were built. The following depths were reached in the Lorenzschacht :

|

|

|

The following levels on this shaft are known: 370 m, 7th underground level (TBS), 405 m, 9th TBS, 480 m, 11th TBS, 12th TBS, 600 m, 14th TBS, 15th TBS, 720 m. A separate main shaft went from 707 to 925 m depth (levels: 17th to 19th TBS, 920 m level), a second blind shaft of 898.9 m to the total depth of the pit, 1025.2 m (20th to 22nd) . TBS). The deepest, 22nd level was at a depth of 1020 m. A third blind shaft was located further up between 600 and 680 m depth (i.e. between the 13th, 14th and 15th underground level).

Around 1900 the mine went to Phönix AG for mining and smelting operations.

advancement

|

|

|

|

After the production of the mine was below 1,000 t in the 1850s, iron ore was mined above this level for the first time in 1861 with 1,120 t. Production rose to 10,000 t by 1869 and fluctuated up to a maximum of 20,000 t until the 1890s. In the 1860s, the Bautenberg was temporarily on the 10th place in the mining statistics in the Siegerland ore district. In 1885, 32 t of zinc blende and 84 t of lead ore were mined in addition to iron ore. From 1900 the production increased steadily, the strongest mining took place in 1909 with around 90,000 t. Funding was continued until 1941, there were small slumps after the First World War and the Great Depression in the early 1930s, but without a full year without funding. In the year of closure in 1942, the mine was producing almost 1,500 t of iron ore.

Pit fire and water ingress

On June 7, 1917, a fire broke out in the pit. On a floor between 445 and 480 m, a miner's lamp was probably the cause of the fire. The fire could only be extinguished after a week after it was sealed and temporarily closed. One death was to be lamented, however. A miner was stunned by the poisonous gases and fell into the depths.

In 1938, workers encountered groundwater on the 720 m level in the “Landeskron” work tunnel . At first it was believed that the water would come from the Landeskroner Weiher, as the tunnel ran in this direction. The water was pumped out of the tunnels for days, but since the pond did not empty, the theory was quickly abandoned. The 1020 m level and the 720 m level ran full. Working cattle drowned in the pit, equipment and tunnels were flooded. Fortunately, all workers were able to save themselves from the water in time, no one was harmed. Three months pumped to the water from the mine before the work could be resumed.

Manhole break and closure

In October 1941, a cage in the Lorenzschacht running diagonally outside the guide tore the shaft wall above the 270-m-level. The repairs were difficult and took longer than expected. When the shaft collapsed again on the night of March 30 to 31, 1942, there were around 300 miners underground. They could climb outside using ladders. It was decided to close the mine and production was stopped, although there was still enough ore in the earth. It was officially closed on July 17, 1948. In the 1950s, some of the existing facilities were demolished, and an industrial company for machine and apparatus construction, the "Bautenberg GmbH", was established on the mine site.

The total production of the mine was 2.869 million tons of iron ore (other source 3.4 million tons).

In 1935, a 1.7 km long straightening section was driven from the 720 m level into the Landeskroner mine field in order to examine the depths of the corridors there. After a length of 1,540 m, a 3 m thick spate iron stone entrance was approached, which was developed over a length of 250 m. However, due to a water ingress, this work had to be stopped in 1938.

In 1958/59, the mine was examined again for ore deposits.

Workforce

| year | Workforce |

|---|---|

| 1910 | 475 |

| 1911 | 419 |

technology

The Grüne Hope shaft, built in 1871, was equipped with a 25 HP horizontal twin steam engine and a 50 HP double-acting vertical dewatering machine. To supply the machines there was a chain lift from the mine site in the upper valley to the shaft. This runway was later extended to the new shaft. The winding machine of the Lorenzschacht consisted of a steam engine , this was housed in a larger room in the winding machine house. At both ends of the axle there were flywheels with a diameter of approx. 5 m, with a wire rope drum in between. The wire rope ran from the building to the headframe and over running wheels into the shaft. The end was attached to the hoist cage . This held four mine cars.

The hoisting machine was operated in the engine room. Since the loaded mine car had to go from the conveying level (720 m) to the 100 m level through the 1000 m long conveyor tunnel in the direction of Unterwilden for processing, the hoisting machine was also operated in 3-shift operation. So that the machinist in the engine room knew what to do and when, there was a bell with a hammer and a wire rope that led into the shaft. The so-called " attacker " gave the signals upwards. In the separate main shafts between the 720 m and 1020 m levels there were electrically operated hoisting machines , known as " reels ". In the boiler house , the water for the steam engines was heated with hard coal . In the forge , the miner's lamps were cleaned, repaired, tested and refilled with carbide and water. This work was mainly carried out by disabled people.

The old preparation consisted of a 16-hp steam engine, a stamping mill , various separation drums and jigs . From 1910 a new ore processing facility was built, which was operated with a simplified process until 1930. In addition to processing, the roasting plant was expanded. The ore was crushed in the processing and cleared of dead rock, as well as separated according to ore type before it was either dispatched or was roasted.

The two pumps for dewatering managed up to 2 m³ of water per minute.

See also

literature

- Kurt Becker (ed.): Our fathers - the miners of the Bautenberg mine between Gilsbach and Wilden, Dill and Westerwald. Dillbrecht 1994.

- Gerd Bäumer: Bautenberg - Largest mine in the Wild Valley. In: Magma. 1984.

Web links

- The Bautenberg mine . Heimatverein Zeppenfeld, 26th Zeppenfeld history letter

- Gerd Bäumer: Ore mining in the Siegerland area . ( Memento of November 7, 2001 in the Internet Archive )

Individual evidence

- ↑ a b c d e f g h i j k l m H.D. Gleichmann: The Bautenberg mine near Unterwilden

- ↑ a b c d e T. Hundt, G. Gerlach, F. Roth, W. Schmidt: Description of the mountain areas Siegen I, Siegen II, Burbach & Müsen. Bonn 1887.

- ↑ "26th Zeppenfeld history letter: Die Grube Bautenberg" of the Heimatverein Zeppenfeld ( memento of October 9, 2007 in the Internet Archive )

- ↑ a b c d MGV "Sangeslust" Wilden: Festival and homeland book, published on the occasion of the flag consecration of the MGV "Sangeslust" Wilden on July 16 and 17, 1955. Wilden 1955.

- ↑ Journal for the mining, smelting and salt works in the Prussian state. Berlin, edition 1869.

- ^ Gerhard Schäfer: The valley railway in the free reason. In: Regional traffic history. Volume 24. EK-Verlag, Freiburg 1998.

- ↑ a b c d 700 years of Neunkirchen. Otto Braun publishing house, Neunkirchen 1988.

- ↑ Journal for the mining, smelting and salt works in the Prussian state. Berlin, edition 1863.

- ↑ Journal for the mining, smelting and salt works in the Prussian state. Berlin, edition 1866.

- ↑ The deposits of usable minerals etc. , third section

- ↑ Annual reports of the chambers of commerce and commercial corporations of the Prussian state: 1869. Berlin, 1870 edition.

- ↑ Annual reports of the chambers of commerce and commercial corporations of the Prussian state: 1872. Berlin, 1873 edition.

- ↑ Journal for the mining, smelting and salt works in the Prussian state. Berlin, edition 1874.

- ↑ Journal for the mining, smelting and salt works in the Prussian state. Berlin, edition 1898.

- ^ A b Hans Dietrich Gleichmann: The Füssenberg - The great time of the Siegerland iron ore mining. Bertelsmann Fachzeitschriften-Verlag, Gütersloh 1994.

- ↑ a b c d Glückauf. Berg- und Hüttenmännische Zeitschrift , No. 49, December 20, 1913

- ↑ Journal for the mining, smelting and salt works in the Prussian state. Berlin, edition 1910.

- ↑ Journal for the mining, smelting and salt works in the Prussian state. Berlin, edition 1914.

- ↑ Journal for the mining, smelting and salt works in the Prussian state. Berlin, edition 1862.

- ↑ Journal for the mining, smelting and salt works in the Prussian state. Berlin, issues 1864–1867.