Compensation (clock)

As compensation is referred to in the watchmaking a special design or material selection to compensate for disturbing environmental influences on the transition of a clock.

This article relates to wheel clocks with pendulum or balance wheel and to fluctuations in temperature and air pressure, but not to the compensation of shocks ( shock protection ) or the evenness of the running spring mechanism ( worm and stackfreed ).

properties

The clock state is the deviation of the displayed time from the true time at a specific point in time. The clock position is corrected by setting the hands; it is not yet a quality criterion in itself.

The course of the clock is the change in the state of the clock over time, the clock may go ahead or behind. A constant gait error is also not yet a quality criterion. The aim of compensation is to achieve a clock rate that is as constant as possible, which can then be compensated for by fine-tuning the pendulum length or the spring tension .

Pendulum clocks

Temperature compensation

The thermal expansion of the pendulum rod makes the clock slower as the temperature rises. Part of the effect is compensated by the decrease in the density of the air and thus the buoyancy of the pendulum body, see below . The remaining effect can be reduced by using materials with low expansion coefficients.

Selected, prepared wood gave quite useful results for early pendulum clocks. The expansion in the direction of the fibers is significantly less than with most metals. Against the swelling influence of humidity , wooden pendulum rods are well impregnated by treating them with linseed oil and usually also painting them.

Since the beginning of the 20th century, materials with the lowest possible coefficient of thermal expansion have spread, especially in the area of evacuated precision pendulum clocks . Here, the standard Invar FeNi36, the first invar alloy to be discovered, made of around 36% nickel and 64% iron, has prevailed over quartz glass , which is still less expandable . In addition to the existing brittleness , the connection with the pendulum suspension and pendulum mass also proves to be more critical with glass rods.

Before being used in precision watches, Invar rods are subjected to artificial aging in the form of alternating mechanical and thermal loads. This is used to relieve internal stresses that would lead to unpredictable changes in length.

Rust pendulum

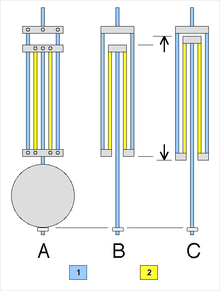

In the case of a grate pendulum ( rust in the sense of a grid , synonymous with Harrison's compensation pendulum ), the different coefficients of thermal expansion of steel / iron and brass (or other alloys) were used. Several bars made of these metals were attached to a lower and two upper bars side by side, so that the total length of this arrangement remained largely constant with changes in temperature. Rust pendulums were developed around 1725 by John Harrison and 1753 by John Ellicott the Younger (1706–1772). These pendulums were very common among the so-called regulators and were considered a quality feature. As a result, they were often forged on inferior watches and had no function, as the rods were all firmly connected to one another or were made of the same material.

In the picture on the right, the movement with a change in temperature is exaggerated for illustration: a material 2 (yellow, e.g. brass) with high thermal expansion is combined with the remaining material 1 of the pendulum rod (blue, e.g. iron) in such a way that the total thermal expansion cancels. The webs shown in full in the left partial image are only connected to the rods at the points marked with circles; the rods protrude freely through holes at the remaining points.

Riefler pendulum

The Riefler pendulum works in a similar way to the grate pendulum using different materials. By using Invar steel for the pendulum rod, however, the compensation on sleeves between the pendulum nut and lens can be reduced. Riefler suggested combining different sleeves of the same overall length in order to be able to adjust the strength of the compensation within wide limits independently of the oscillation frequency.

Mercury pendulum

The mercury pendulum (synonymous with Graham's compensation pendulum ) is based on the same principle and uses the great thermal expansion and density of mercury . The model developed in 1726 by the Englishman George Graham had an open-topped tube filled with mercury as a pendulum weight.

Air pressure compensation

As the air pressure increases, the density of the air increases. This increases the static buoyancy of a pendulum weight. This increases the period of the pendulum. In addition, the increased density can increase the air resistance of the pendulum and thus increase its damping. This also leads to a longer period. The air pressure has an influence on the damping of the oscillation if the flow is turbulent, while the viscous friction hardly depends on the pressure. The air pressure constant of a second pendulum is, depending on the shape of the pendulum body and its density, approx. 0.01 to 0.02 seconds per day per millibar change in pressure.

On average, the air pressure at sea level is 1013 mbar. Both the standard deviation of the fluctuations due to weather events and the amplitude of the annual cycle are around 2 to 20 mbar, depending on the location. It follows from this that a single extreme weather event can change the level of a precision pendulum clock by a whole second and that the monthly error can have an annual cycle of a few seconds.

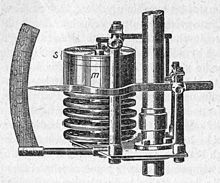

Such deviations could not be tolerated for the clocks of time service systems. After unsatisfactory experiments with mercury and siphon barometers, on the advice of the astronomer Professor Wanach, at the end of the 19th century, the Clemens Riefler company in Nesselwang and Munich developed air pressure compensation using aneroid cans , as is also used in can barometers and altimeters . The arrangement of the aneroid box compensation consists of several boxes connected in series, which are loaded with a weight. The weight is moved by the cans depending on the air pressure along the pendulum rod and thus changes the moment of inertia of the pendulum.

An alternative method is to put the pendulum clock in a pressure-tight and sealed container, e.g. B. made of glass, so that there was a constant air density. This eliminates the need for compensation, and the vessel can also be evacuated so that air damping is also eliminated.

Clocks with a balance

In addition to the self-regulating mechanisms of compensation is at more complex Klein watches a manual usually additionally regulator .

Temperature compensation

The considerable temperature variation of watches with a balance mainly results from the temperature-dependent elasticity of the balance spring and the resulting change in frequency . Due to a lower material fatigue than other materials available at the time, John Harrison used spiral springs made of spring steel and, from 1753, bimetallic balance wheels in his H4 and H5 marine chronometers . The temperature-dependent curvature of the two hoop segments results in a reduced moment of inertia of the balance wheel with increasing temperature to compensate for the lengthening of the balance spring and the associated reduced frequency.

Around 1765, Pierre Le Roy (1717–1785) discovered that the balance wheel can be fitted with adjustable ground screws to compensate for temperature fluctuations. Such a compensation balance or screw balance has adjusting screws for changing the frequency and the center of gravity of the balance. Around 1770 Pierre Le Roy developed a compensation balance with a closed metal ring on which two small mercury thermometers were attached for compensation.

The essential material properties for the balance spring of a balance wheel are low material fatigue, low corrosion and independence from external influences. Abraham-Louis Breguet used, among other things, a spiral spring made of gold . Charles-Auguste Paillard used a coil springs for palladium - alloy . After the discovery of negative volume magnetostriction by Charles Édouard Guillaume became increasingly Invar , later Elinvar also used as one of the two metals or alone, which is referred to in the latter case than monometallic balance wheel. The elasticity and temperature resistance of the Elinvar led to an increasing use also for spiral springs, until the Elinvar was gradually replaced by Nivarox or silicon for spiral springs . In the 20th century, temperature-resistant balance wheels made of metal alloys (e.g. Glucydur ) or silicon were developed so that adjusting screws are no longer technically necessary. However, they are occasionally used for design reasons.

Position compensation

Small watches usually experience different positions, which means that different gravitational forces act on the moving parts of a watch. The tourbillon is a mechanism for reducing the positional error by constantly rotating the escapement and balance wheel, e.g. B. in two dimensions with the tourbillon, the orbital tourbillon or the carousel (French caroussel ). Rotating in three dimensions, the escapement and balance are z. B. the gyroscope , the gyrotourbillon , the spherotourbillon or the triple-axis tourbillon . With the quadruple tourbillon , four tourbillons compensate for four planes of position.

literature

- Hans von Bertele, Ernst von Bassermann-Jordan: Watches - A manual for collectors and enthusiasts , Klinkhardt & Biermann, 1982, ISBN 3-7814-0205-3 .

- Klaus Erbrich: Precision pendulum clocks: from Graham to Riefler , Callwey, 1978, ISBN 3-7667-0-429-X .

- Samuel Guye, Henri Michel: Clocks and measuring instruments , Orell Füssli, 1971.

- Rudi Koch (Ed.): Clocks and time measurement , BI-Lexikon, VEB Leipzig, 1986, ISBN 3-323-00100-1 .

- Anton Lübke: The clock , VDI, 1958.

- Fritz von Osterhausen: The great watch lexicon , Heel, 2005, ISBN 3-89880-430-5 .

Individual evidence

- ↑ a b G. A. Berner: Illustrated specialist lexicon of watchmaking , electronic version, keyword pendulum. Retrieved July 28, 2014.

- ↑ Nadja Saleck: Change in storm activity over the oceans, investigated using atmospheric pressure observations. Dissertation, Univ. Kiel, 2005.

- ^ Riefler, Dieter: Riefler precision watches: 1890-1965 ; Callwey Verlag, Munich 1991, ISBN 3-7667-1003-6 , pp. 74f.

- ^ GA Berner: Illustrated specialist encyclopedia of watchmaking , keyword Paillard (Charles-Auguste) . Retrieved February 17, 2012.