Capacitor power supply

A capacitor power supply is a special form of a power supply . It uses the reactance of a capacitor as a capacitive series resistor to reduce the mains voltage ( low voltage ). Because of the demands on the capacitor and the ohmic series resistor, it is only used for low currents of up to a few 10 milliamps . The advantage of its low component cost is paid for by various disadvantages, e.g. B. Due to the lack of galvanic isolation, the electrical devices supplied with them must be encapsulated in a safe way.

application

With capacitor power supplies, electronic circuits with low power consumption are connected to the mains voltage in an energy-efficient and cost-efficient manner. Capacitor power supplies are particularly suitable for low currents, because the principle supplies a certain current - the voltage drawn must be stabilized by means of a parallel regulator if the current consumption fluctuates . The higher the required output voltage and the lower the power consumption, the smaller the dimensions of the capacitor. Capacitor power supplies are therefore particularly suitable for high output voltages and low power consumption. The efficiency is limited due to the possibly existing parallel regulator and a protective resistor that is always required (protection of the rectifier or the subsequent circuit against voltage transients in the network and when switching on).

At low currents, capacitor power supplies are smaller, cheaper and lighter than conventional ( switching ) power supplies or power transformers . Due to the lack of electrical isolation , the use normally restricted to built-in electronics in devices with power such. As for the operation of LED lamps in the lower power range, as well as for self-supply of the controller of twilight switches , motion detectors , remote control receiver , electronic timers , time relays and similar devices.

In the case of higher power requirements, down converters that are not galvanically isolated are used, which, however, generate correspondingly more interference emissions due to their clocked mode of operation .

history

In the 1980s, capacitor power packs replaced the 50 Hz transformers available at the time when connecting DC motors up to 3 W with operating voltages from 3 V to 24 V. The purchase was cheaper. The discharge resistor for the capacitor (R2, see below) was not always necessary in the control systems, which resulted in a high efficiency of 60 to 90%. A self-healing 2 µF capacitor (approx. 147 mA) cost as much as a 1 VA transformer. In addition, transformers with an output power of less than 1 VA were not available.

The area of application has been shrinking since the development of low-power switched-mode power supplies in the 1990s because of the higher efficiency of switched-mode power supply technology compared to the transformer power supplies previously used. The size of the capacitor in the capacitor power supply increases proportionally with the current that can be drawn and exceeds the size of a comparable switched-mode power supply with a comparable efficiency at approx. 66 to 100 mA output current.

Inexpensive step-down converters with low internal consumption have been available since around 2008 and the area of application continues to shrink. Even with an output current of 2 mA, these step-down converters are smaller than capacitor power supplies, but are less efficient because the converter itself requires an auxiliary voltage with a current of 1 mA to 1.5 mA, which is drawn from the 230 V mains voltage via an ohmic series resistor is generated (as of 2014).

Capacitor power supplies are often used in retrofit LED lamps because they do not require galvanic isolation, but rather a small size. Often, for reasons of cost and space, the smoothing capacitor is omitted or dimensioned too small, which leads to strong flickering of the lamps. Here, too, depending on the price range, step-down converters are increasingly being used, which is often, but not necessarily, associated with the use of a smoothing capacitor.

construction

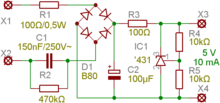

A capacitor power supply consists of a capacitor C1, whose reactance limits the current through the rectifier D1. An ohmic resistor R1 is connected in series in order to limit the current peak when switching on and due to possible defects in the voltage quality from the supply network ( surge and burst ) . An electrolytic capacitor C2 smooths the DC voltage and buffers the current peaks when the load changes. A voltage regulator can be connected downstream, here consisting of a current limiter resistor R3 and a cross regulator IC1. If there is less demand for constant voltage, a reverse- biased Zener diode can be used. A backup is also required.

A power source is practically created from the mains voltage and reactance C1 . This means that the current flow through R3 is almost constant. Capacitor power supplies are therefore ideal for constant current consumers such as LEDs . The active power consumption of this circuit results from the forward voltages of the rectifier diodes added to the output voltage set at C2 multiplied by the current, plus the power at R1 and R2.

The capacitance of the capacitor C1 is approximately 22 nF to over 1 µF. For capacitors with a tolerance of ± 20%, for a bridge rectification of up to 25 volts output voltage, taking into account all other tolerances in the circuit, the capacitance can be roughly determined at 15 nF per milliampere output current. For a half-wave rectification (modified Greinacher circuit ) an approximate 30 nF per milliampere output current should be provided. Capacitors with a smaller tolerance range increase the energy efficiency, so that with a tolerance of ± 10% the roughly calculated capacity can be reduced by 10% and for a tolerance of ± 5% by 15%. In order to achieve the calculated value of the capacitance exactly with capacitors from the E6 series (± 20% tolerance) or E12 series (± 10% tolerance), capacitors of different sizes are connected in parallel , for example 33 nF, 6.8 nF and 2 , 2 nF if the calculated value is 42 nF. Choosing the next higher value of 47 nF (E12 series) would be possible, but it reduces the efficiency of the capacitor power supply.

A resistor R2 of 470 kΩ to 1 MΩ must be connected in parallel to the capacitor C1. It discharges the capacitor after the device is disconnected from the mains. Otherwise you could get an electric shock if you pull out the plug of the device. In the case of purchased devices, the time constant for the discharge of C1 through R2 is around 70 ms to 1.5 s. Taking into account all tolerances, a time constant of 0.07 s ensures discharge to a voltage below 50 volts within 0.2 seconds. The active current, which flows parallel to the capacitor C1 during operation, is around 5% of the reactive current through the capacitor, which hardly affects the output current due to the phase shift between active and reactive current. In permanently installed devices or systems, the C1 may not need to be discharged.

Despite the ohmic resistance R1 connected in series (from 47 Ω upwards, usually in the range 330 to 5600 Ω, depending on the pulse current resistance of the fuse and the connected components for switch-on and overvoltage ), so-called X-capacitors (e.g. B. MKP 630 V = / 250 V ~) can be used, because in the 230V network shorter and longer lasting overvoltages occur, u. a. so-called transients , which can have up to 6 kV and normally occur several times a day in the range up to 2 kV. The series resistor absorbs part of this voltage; however, the capacitor must be sufficiently voltage-proof and, if necessary, fail without risk of fire. Many X capacitors are self-healing , capacitor power supplies can fail if the capacitor is of unsuitable quality.

A fuse must be connected upstream, either as a separate component, or the resistor used is a so-called fuse resistor (English fusible type ) and thus, in addition to its actual function, also represents a fuse and does not ignite if the capacitor breaks down. For this reason and also because of the higher dielectric strength, metal film resistors are recommended . In addition, the resistor must be voltage and pulse-proof so that it does not explode even with strong transients.

A capacitor power supply always requires a load that prevents excessive voltages at the output. In a few cases, the load itself can adapt the operating point to changes in voltage and component tolerances and completely cut off the current if the load fails, e.g. B. with LED lamps. In the other cases, a variable load connected in parallel must stabilize the output voltage, even if the connected load fails completely. Zener diodes, overvoltage protection diodes and cross regulators are suitable. Cross regulators stabilize voltages better than Zener diodes, but they require some current to operate their internal electronics and can only dissipate low impulse currents. Their voltage can often be selected using a voltage divider . Zener diodes can withstand short-term high overcurrents and have a low leakage current of a few microamps, but the value, spread and temperature coefficient of the Zener voltage are fixed.

Ripple control pulses and similar high-frequency interference voltages superimposed on the network can load capacitor power supplies or the loads connected to them.

If the capacitor power supply operates a control circuit for a relay , the relay coil is connected in series with the control circuit. Relays with 24 to 48 volts are suitable, as they require a low current, which, however, has to be slightly larger than that of the control circuit. This leads to power savings and better efficiency thanks to smaller C1 and R2. When operating on a constant current source, a relay is switched off by the switching transistor short-circuiting the voltage on the relay. Due to the low voltage on the transistor, the active power is close to zero. If the transistor does not conduct, the relay switches on.

If the capacitor power supply is used to control a triac , a diode half-bridge is used, which provides a voltage of typically 5 V, which is negative compared to a pole of the mains voltage (= cheaper to ignite the triac). The current yield compared to the o. A. However, the full bridge is only half as large with the same dimensions, which is why relays are often used for larger loads that are switched less often, for example in kettles .

Efficiency

The efficiency of a capacitor power supply is moderate to very good, depending on the conditions of use. The series resistance R1 and the discharge resistance R2 in particular determine the efficiency. In general, the efficiency is higher when the output voltage is high and the output current is low. That is why series connections are preferred to parallel connections. LED lights with many individual LEDs connected in series or devices in which the same current flows through several circuit parts implement this principle.

Compared to other power supply and converter technologies, the capacitor power supply is more efficient at low output currents. The efficiency of various power supply units and ballasts for an electronic load / circuit to be supplied that requires 6 V ± 20% at 2 mA, for example:

- approx. 62–75% - capacitor power supply, 5.6–6.6 V through Z-diode (required control current ≥200µA), 10% tolerance of C1, without R2

- approx. 36–45% - capacitor power supply, 6 V through cross regulator (required control current ≥1100µA), 10% tolerance of C1, without R2

- approx. 18–19% - capacitor power supply, 5.6–6.6 V through Zener diode (≥ 200µA), 10% tol. C1, R2 discharges C1 with a time constant of 70 ms

- approx. 13% - capacitor power supply, 6 V through cross regulator (≥ 1100µA), 5% tol. C1, R2 discharges C1 with a time constant of 70 ms

- approx. 12–13% - capacitor power supply, 6 V through cross regulator (≥ 1100µA), 10% tol. C1, R2 discharges C1 with a time constant of 70 ms

- approx. 9–11% - capacitor power supply, 6 V through cross regulator (≥ 1100µA), 20% tol. C1, R2 discharges C1 with a time constant of 70 ms

- approx. 10.7% - 6V switching power supply without LED function display, 300 mA max., 6 V stabilized, 0.10 watt power loss

- approx. 5.4% - universal switching power supply with LED function display, 300 mA max., setting 6 V, 0.21 watt power loss

- approx. 3.4% - step-down converter, stabilized at 5.6–6.6 V and 2 mA, auxiliary voltage generation with 0.49 watt power loss

- approx. 2.1–2.4% - ohmic series resistor with 5% tolerance, 5.6–6.6 V through Zener diode (≥200µA)

- approx. 0.7% - universal transformer power supply 500 mA max., 3 V unregulated, real 6.9 V at 1.62 watt power loss

Web links

- Microchip Application Note AN954 (PDF; 255 kB)

- Capacitor instead of transformer: Inexpensive power pack in the electronics compendium

- Auxiliary voltage generation in 50 Hz technology

- Description Impulse-proof, metallized structure (MKP capacitor) from the manufacturer WIMA

literature

Low voltage motors on the lighting network without a transformer. In: Michael Kohl (Ed.), In: 'JET - Der Junge Elektro-Techniker.', Frankfurter Fachverlag, Frankfurt am Main, April 1988, pages 153-155, ISSN 0935-6088 .

Individual evidence

- ↑ a b c d e Michael Kohl (Ed.): Extra-low voltage motors on the lighting network without a transformer. , in: JET - The Young Electrical Technician. , Frankfurter Fachverlag, Frankfurt am Main, April 1988, pages 153-155, ISSN 0935-6088 .

- ↑ Sheng-Yi Chuang: Patent on LED lamp with capacitor power supply US20100045206, Fig. 5 , February 25, 2010, accessed on November 5, 2017 (English).

- ↑ ITT Intermetall (Ed.): Circuit examples with discrete semiconductor components. , Freiburg 1972, pp. 16-21.

- ↑ Thomas Schaerer: Capacitor power supply - capacitor instead of transformer: Inexpensive power supply. In: Elektronik-Kompendium.de. May 27, 2017, accessed April 10, 2020 .