Pneumatic car (SBB)

| SBB tires | ||

|---|---|---|

Trial train with B10ü (left) and C10ü, approx. 1951 |

||

| Technical specifications | ||

| design type |

1950: B10ü 1951: Bp4ü 1956: Ap4ü 1963: A |

1950: C10ü 1951: Cp4ü 1956: Bp4ü 1958: B4ü 1963: B 1966: X4 1973: X |

| numbering |

1950: 2501 1963: 2290 1970: 18-33 090 |

1950: 6501 1956: 5901 1959: 5991 1966: 91149 1976: 99 33-300 |

| Manufacturer car body | SIG | Streaks |

| Material car body | aluminum | Structural steel |

| Manufacturer of bogies | 1950: Carel Fouché & Cie. | |

| 1958: SWP | ||

| Construction year | 1950 | 1950 |

| Retirement | 1985 | 2000 |

| number | 1 | 1 |

| Axis formula |

1950: 5'5 ' 1953: 4'4' 1963: 2'2 ' |

1950: 5'5 ' 1959: 2'2' |

| Gauge | 1435 mm | |

| Axle distance bogies | 3,940 mm | |

| Wheel diameter | Tire tires: approx. 880 mm | |

| Pivot spacing | 14.3 m | 14.43 m |

| Floor height | 1075 mm | 1071 mm |

| Entry height | 530 mm | 524 mm |

| Seats | 2nd class: 46 | 3rd class: 76 |

| Seat divider | 2 + 1 | 2 + 2 |

| Weight (empty) | 12.7 t | 14.2 t |

| Weight (occupied) | 16.2 t | 19.9 t |

| Bogie weight | 2.1 t | |

| Car body weight | 8.5 t | 10.0 t |

| Weight / seat | 276 kg | 187 kg |

| Axle travel mass (empty) |

1950: 1.27 t 1953: 1.6 t 1963: 3.18 t |

1950: 1.42 t 1959: 3.55 t |

| Length over buffers | 21.3 m | |

| height | 3.6 m | |

| width | 2.92 m | |

| Vmax | 125 km / h | |

| Brakes |

1950: Compressed air controlled hydraulic brake after conversion to normal bogies: Compressed air brake |

|

The Pneuwagen the SBB were two coaches , as test vehicles with tires from Michelin were equipped. The wagons were the first light steel wagons in Swiss industry with a center entry for the SBB.

history

Development of pneumatic rail vehicles

In the 1930s, the Michelin management commissioned their technical departments to develop a tire for use in rail vehicles . Due to the heavy weight of the railway vehicles and the small contact area on the rails, the task seemed almost impossible to solve. After intensive studies and numerous tests, however, the first 24-seater Micheline railcar was put into service at the Chemin de fer de l'Est in March 1932 . Other vehicles with pneumatic tires followed.

Compared to classic railway vehicles with steel wheels, the pneumatic-tyred vehicles were quieter because less noise was generated when the wheels rolled and when driving on rail joints, but they had the disadvantage of greater rolling resistance. Until the Second World War , the technology of pneumatic rail vehicles was limited to individually traveling railcars . In 1939 Michelin proposed the construction of passenger coaches with pneumatic tires, which immediately aroused the interest of the SNCF. In 1947, Deutsche Bahn ordered three trains called Train sur pneus , each with six air- tire cars, which later ran on the Paris – Strasbourg route at a top speed of 100 km / h.

Order the SBB wagons

As early as 1938, SBB became interested in Michelin technology. Delegates from the SBB General Directorate were invited to a demonstration drive in an electric multiple unit intended for suburban traffic in Paris. They were enthusiastic about the vehicle with pneumatic tires and praised its smoothness and the short braking distances . The technical departments of SBB discussed the construction of new cars for passenger trains with Schlieren , SIG and Michelin. The study was interrupted by the Second World War and could not be resumed until 1946.

On December 20, 1947, the SBB General Directorate signed the contract for the construction of two test cars. These were the B10ü 2501, a 2nd class car with an aluminum car body from SIG , and the C10ü 6501, a 3rd class car with a steel car body from Schlieren . Both cars received five-axle bogies from Carel Fouché & Cie. , the same ones that were intended for use on SNCF trains on the Paris – Strasbourg route.

With the two particularly light test cars, the SBB wanted to test the suitability of the pneumatic-tire bogies with the hydraulic braking system on the winding and incline-rich Swiss route network. They also wanted to compare the two types of box with each other and examine whether the expected increase in comfort through the noise reduction would come true.

Installation

The cars were completed in the summer of 1950 and subjected to a series of technical tests in which the braking distance was determined, the safety devices for monitoring tire pressure were checked and the suspension and shock absorbers were adjusted. The braking force of the pneumatic cars had to be adapted to that of the existing light steel cars, which was ensured by an adjustable pressure reducer in front of the pneumatic-hydraulic pressure intensifier . Because the wagons were unusually light, there was a big difference between empty and fully loaded. For example, the 2nd class car with a payload of 80 passengers of 75 kg was calculated, which was 6 t or 42% of the curb weight. Because both automatic load braking with weighing valves and anti-skid protection were still unknown at the time, it was hardly possible to prevent the wheels from locking when the wagons were empty and the rails were poor.

The coordination of the suspension and dampers turned out to be difficult. Because the cars had no primary suspension due to the pneumatic tires, only the secondary suspension could be changed. Due to the large weight difference between empty and full, this had to be chosen to be very stiff so that the occupied wagons did not deflect too much. In addition, one apparently had to struggle with natural resonance of the very light car body during commissioning .

commitment

Even before the wagons were used, they were no longer called B10ü and C10ü, but Bp4ü and Cp4ü, where the p stood for pneumatic tires and the number 4 expressed that the wagons behaved like a four-axle wagon in terms of braking despite their ten axles. From December 1950, the cars ran in light express trains on the Biel – Bern and Bern – Lucerne routes , where they covered around 650 km per day.

In 1953, the 2nd class car received new bogies with pneumatic tires that only had four axles instead of five. Nevertheless, the main evils of the car could not be remedied. Due to the extremely lightweight construction , there were large vibrations, especially at high speeds, which made themselves unpleasantly noticeable as noise and nullified the hoped-for advantage of the quiet pneumatic tires. Furthermore, the rolling resistance of the tires was up to four times higher than that of ordinary railroad cars. The large amount of tire wear resulted in high maintenance costs. Because of the low wheel contact force, the wagons tended to derail and in winter the wheel flanges had a tendency to climb up on snow-covered level crossings .

Thus, after only four years, the cars disappeared from the express train service and were transferred to the Vevey-Puidoux-Chexbres route in 1954 . The line has gradients of up to 44 ‰, which is why the light cars appeared to be particularly suitable for this use together with an Fe 4/4 multiple unit.

With the abolition of the old 1st class in 1956, the 2nd class became the new 1st class and the 3rd class became the new 2nd class. Thus, the cars now had the designations Ap4ü and Bp4ü.

Use without pneumatic bogies

The pneumatic bogies disappeared at the end of the 1950s. The 2nd class car was again given a special bogie design. This time it was the first bogies with air suspension developed by Schindler Waggon Pratteln (SWP) . The version with an H-frame corresponded roughly to that of the other light steel wagons. Instead of the primary springs, four air springs were used. These were already provided with a level control . In this context, the car also received the multiple control line so that it could be used in the Re 4/4 I commuter trains Bern - Neuchâtel - Le Locle . The new bogies proved their worth and the car covered a distance of 293,000 km by 1963. Nevertheless, the bogies were exchanged for those of the normal version in order to standardize the types. After an accident in 1965, the car was converted into a special car for medical examinations. In this function, he last carried the number X 60 85 99-33 300-2, with which he was scrapped in January 2000 and broken off in 2001.

The 1st class car received normal SIG torsion bar bogies and the multiple control line in 1963. He was to be found for years on the Gipfeli-Express, a morning workers' commuter train from Einsiedeln to Zurich, which traveled the 50 ‰ ramp of the SOB . It was scrapped in July 1985.

Although the cars were on the road for a much longer phase of their service life without pneumatic bogies, the staff referred to them as pneumatic cars right up to the end .

technology

Building the car was a constructive challenge. Since a tire with pneumatic tires could only be loaded with a maximum of 1100 kg, the car could not be heavier than 22 t when fully occupied, in order to prevent the maximum load of the 20 wheels from being exceeded. Because the two bogies together were already calculated at 5 t, only 11 t remained for the car body with interior fittings. That was only half of a conventional light steel car, which had already saved a third of the weight of a normal steel car. Nevertheless, the wagons should have the same structural strength as the light steel wagons, as well as have side buffers and screw couplings so that they could run together with the other light steel wagons.

Attention was paid to saving weight right from the overall arrangement. A single entry was arranged in the middle of the car, instead of the usual two end entrances. Furthermore, only one instead of two toilets was arranged, which was also in the middle of the car. The structure of the car body was designed as a self-supporting beam. In order to achieve the required weight reduction, it was essential to use only very thin metal sheets that were reinforced and shaped so that they could not buckle. Therefore, large free sheet metal areas and long self-supporting parts had to be avoided. The above measures made it possible to keep the weight of the body shell low. The steel car body of the 3rd class car weighed 5 t, the aluminum car body of the 2nd class car weighed 3.25 t.

The heating and lighting were the same as in the other coaches. The alternator was not attached to the outside of the bogie, but was placed under the floor of the car. It was driven by an axle drive on the inner axis of a bogie via a cardan shaft. As a novelty, loudspeakers were installed in a passenger coach for the first time . They did not yet have a function in regular trains, but were only used in company trains, for which a microphone , record player and amplifier could be set up and connected in the anteroom . The 220 V AC devices were powered by a small rotating converter from the 36 V network.

In contrast to the normal railway cars, the pneumatic cars were equipped with a hydraulically operated drum brake , similar to motor vehicles . This brake was controlled using normal compressed air brake equipment, except that two pneumatic-hydraulic pressure intensifiers were installed instead of the brake cylinder. The hydraulic brake equipment was considerably lighter than the equipment of the classic compressed air brake.

Bogies

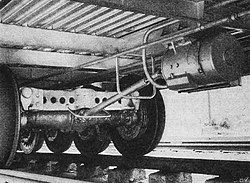

The five-axle bogies from Carel Fouché & Cie from Paris were designed as loose wheel bogies . They consisted of an electrically welded steel frame made of square profiles, in which the fixed axles were held with rubber bearings. On each axle there was a double-row tapered roller bearing for the two wheel hubs . The rim with the pneumatic tire consisting of tube and jacket was screwed onto the wheel hub like a car. The tires were inflated to nine bar and had a tire pressure monitor that responded when the pressure was below 6.5 bar and activated warning lights on the boarding platform. Because, unlike normal bogies, the axles had no primary suspension, a wheel with a defective tire was automatically relieved and the load was taken over by the neighboring wheels. Therefore, in contrast to road vehicles, the wagons could remain in the train for a certain period of time without reducing their speed despite the loss of air in a tire. Two-layer steel belts were worked into the profiled tread of the tires. A steel flange was responsible for guiding the wheel on the rail. To avoid structure-borne noise, this was placed on the extended edge of the rim with a rubber pad.

Because the tires did not establish an electrically conductive connection between the wheel disc and the rail, each bogie had to be equipped with two rail grinders, which had to fulfill three functions: they had to short-circuit the left and right rails so that the track circuits of the signaling systems could recognize the vehicle they had to transfer the return current from the train busbar to the rail and ensure that the vehicle was protected against accidental contact.

After the six-car trains ordered by the SNCF had problems with the secondary suspension, these were designed differently on the two new SBB cars. Both constructions dispensed with a cradle. A solution with torsion bars was chosen for the 2nd class car. In each end member, two torsion bars running inside the side member were firmly clamped. At the height of the central axis, these were connected to the car body with levers and hanging iron. The pivot pin did not transmit any vertical forces, but only served the longitudinal drive. The movement of the torsion bars was limited by a shock absorber attached to the lever of the torsion bar. Two further shock absorbers between the two end axles controlled the pitching movement of the bogie frame.

A solution with coil springs was chosen for the 3rd class car. For each bogie, the car body was supported on the bogie by means of two coil springs at the height of the central axis. The springs were suspended from tie rods, which transmitted the force to yokes arranged lengthways on both sides of the frame, which in turn were supported on the bogie frame via two consoles on each side. The bogies were equipped with an emergency running device that would have been used if parts of the system described above had failed.

literature

- R. Guignard: Les voitures des CFF montées sur pneumatiques «Michelin», part 1 . In: Schweizerische Bauzeitung . tape 69 , no. 12 , March 24, 1951, p. 157–162 , doi : 10.5169 / seals-58831 .

- R. Guignard: Les voitures des CFF montées sur pneumatiques «Michelin», part 2 . In: Schweizerische Bauzeitung . tape 69 , no. 14 , March 31, 1951, pp. 171-174 , doi : 10.5169 / seals-58833 .

- R. Guignard: Les voitures des CFF montées sur pneumatiques «Michelin», part 3 . In: Schweizerische Bauzeitung . tape 69 , no. 14 , April 7, 1951, pp. 183-187 , doi : 10.5169 / seals-58836 .

- We .: About the SBB's new tires . In: Railway amateur . No. 3 , 1951, pp. 61-71 .

Web links

Individual evidence

- ↑ a b c d e R. Guignard, part 1

- ^ E. Schröder: La premiere Micheline électrique type 136 . In: Revue Brown Boveri . September 1939, p. 219-224 .

- ↑ News in brief . In: Railway amateur . No. 2 , 1959, p. 45-46 .

- ↑ Walter Trüb: Did you know that ... In: Railway Amateur . No. 2 , 1981, p. 95 .

- ↑ News in brief . In: Railway amateur . No. 10 , 1985, pp. 679 .

- ^ R. Guignard, part 2

- ↑ M. Frei: Static experiments on car bodies . In: Railway amateur . No. 5 , 1950, pp. 134-136 .