Fracture toughness

In fracture mechanics, fracture toughness or fracture toughness (also crack resistance) describes the resistance of a material to crack initiation. The material parameter is the critical stress intensity factor K Ic at which crack propagation begins.

definition

The fracture toughness or the critical stress intensity factor (for crack opening mode I , stress perpendicular to the crack plane) is defined as

The unit is

It is

- the applied voltage

- the critical crack length

- the geometry factor takes two properties into account:

- On the one hand, the stress intensity factor is theoretically only independent of the dimensions of the test specimen for infinitely large plates

- Furthermore, no stresses can occur at the crack ends perpendicular to the surface, so that an even stress state is established. This ensures, for example, that with a Poisson's ratio of ν = 0.3, the plastically deformed zone is six times wider at the ends than in the middle of the sample.

- The influence of the geometry factor decreases with the specimen thickness, so that the fracture toughness is independent of the specimen dimensions :

With the same materials , the fracture toughness decreases with increasing 0.2% yield strength . As with impact energy , the temperature also has an influence on the fracture toughness; this increases as the temperature rises.

Stress corrosion cracking and fatigue strength

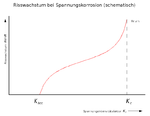

| Crack growth (schematic) | |

|---|---|

Stress corrosion |

Vibration stress |

The fracture toughness also plays a major role in stress corrosion cracking and fatigue strength . A crack occurs here before the failure of the material, which can be characterized by stress intensity factors:

- at a stress corrosion cracking ( Engl. stress corrosion cracking , shortly scc ) K are Iscc the value that can be expected from the crack growth. K Iscc depends on the material and the attack medium .

- In the case of vibration stress , the crack growth is described using the cyclical stress intensity factor

- with the stress range .

Determination of fracture toughness

The fracture toughness can be determined with a compact tension test ( ct for short ). For this purpose, according to DIN EN ISO 12737 , for example, a tensile specimen with a central angular notch is generated (see picture) and a crack is caused by vibration stress. The sample is torn and the tension at which the tear became unstable is measured. The crack extension is also determined.

Since anchor notching causes problems with very brittle materials such as ceramics, other techniques such as SEVNB ( single edge V-notched beam ) or ISB ( indentation strength in bending ) are used. In the former, the specimen is first sawn and then the residual strength is determined in a 4-point bending test. In the second case, anchor notching is carried out using a Vickers pyramid.

Fracture toughness of various materials

Ceramics have the lowest fracture toughness with 1–5 MPa m 1/2 . Thermoplastics behave in a similar way if they are brittle below 0.8 times the glass transition temperature and fail when the critical stress intensity is reached. In contrast, metals with a densely packed crystal structure have a fracture toughness that is 50 to 100 times higher.

The fracture toughness can be increased by incorporating particles or fibers . An example of this is reinforced concrete . If the particles or fibers are ductile , additional energy is required for the composite to fail . However, brittle fibers also increase the fracture toughness, as the crack is deflected and blunted.

Examples

| material | in |

|---|---|

| Metals | |

| Titanium alloys | 44-66 |

| Steels | 50 |

| Aluminum alloys | 36 |

| aluminum | 14-28 |

| Ceramics | |

| Alumina | 3-5 |

| Silicon carbide | 3-5 |

| concrete | 0.2-1.4 |

| Polymers | |

| Polymethyl methacrylate | 1 |

| Polystyrene | 0.8-1.1 |

literature

- Hans-Jürgen Bargel, Günter Schulze (Ed.): Material science . 9th edition. Springer-Verlag, Berlin 2005, ISBN 3-540-26107-9 .

- Joachim Rösler, Steffen Müller, Sebastian Piegert: Materials science . Braunschweig 2006.

Web links

- Experimental determination of the fracture toughness. ( Memento of January 4, 2005 in the Internet Archive ) (PDF; 317 kB)