Ateliers Piccard-Pictet & Cie.

| Ateliers Piccard-Pictet & Cie.

|

|

|---|---|

| legal form | Corporation |

| founding | 1906 |

| resolution | 1920 |

| Reason for dissolution | bankruptcy |

| Seat |

Geneva , Switzerland |

| Number of employees | 1800 |

| Branch | Mechanical engineering , water turbine construction , motor vehicle manufacturer |

| Status: 1920 | |

Ateliers Piccard-Pictet & Cie. was a Swiss company that was engaged in the manufacture of water turbines and automobiles .

history

Predecessor companies

The company goes to the locksmith's shop L. F. Staib & Cie. Founded in 1861 by Louis-Frédéric Staib in Geneva . back, which Jules Weibel joined in the same year , who had been trained as an engineer at the École centrale des arts et manufactures in Paris . The purpose of the company was to manufacture hot air stoves for heating buildings . After the owner's death in 1866, Weibel took over the business, which from then on operated under Jules Weibel & Cie. traded . He made his business more international and presented his products at the World Exhibition in Paris in 1867 , whereby Weibel was supported in these activities by Paul Piccard , who had an engineering degree from the Swiss Federal Polytechnic in Zurich .

Emile Briquet joined the company in 1868 and Jules Faesch became a financial partner. A permanent office was set up in Paris, and the company operated under the new name Weibel, Briquet & Cie. It took part in the 1873 World Exhibition in Vienna , where, in addition to the hot air ovens, stoves for catering and a passenger car with hot water heating were shown.

In 1878 Weibel, Briquet & Cie. for the salt mine Bex a Sole - evaporation plant with heating by thermal compression . This so-called Piccard apparatus is the first system in the world in which the process has been successfully used for production. Even if the system did not quite achieve the promised efficiency, the fuel savings were considerable. In order to exploit the patent for the promising system, the Société pour l'explotiation des brevets Piccard was founded under the direction of Jules Weibel , to which Piccard, Faesch and Albert Filiol also belonged. Another system of the same type was installed in the Ebensee salt works in Austria in 1879 . Before Piccard, Peter von Rittinger had already tried to put such a system into operation, but he was unable to cope with the problem with fouling on the heat exchangers . Piccard introduced a mechanical device to remove the fouling, which could peel the coating off the heat exchanger during operation, which helped the system to break through. Further systems have been installed across Europe.

Faesch & Piccard

Jules Weibel died in 1886. The management of the company was taken over by Jules Faesch and Paul Piccard, the production of heaters to Audéoud & Cie. ceded to concentrate fully on the manufacture of hydropower systems and the company was renamed Faesch & Piccard .

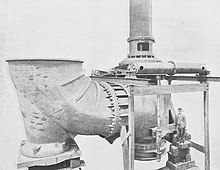

In the same year, the Usine Force Motrice , one of the first hydropower plants with a distribution network, went into operation in Geneva . The energy was distributed with a pressurized water supply , not electricity. The former Weibel, Briquet & Cie. built the metal structures, but not the turbines of the plant, which were supplied by Escher Wyss AG . Paul Piccard developed water turbines to convert the energy of pressurized water into a rotating movement. Piccard developed a hydraulic servo motor with an integrated load controller so that the speed of these turbines was independent of the required drive power . The first version of the regulator used pressurized water as the working medium, but this was not optimal due to the contamination of the water. In the further development, oil was first used as the working medium, before liquids were completely dispensed with in the final version.

The winning of the competition to supply the turbines for the Edward Dean Adams Power Plant can be regarded as the greatest success of Faesch & Piccard . The facility built at Niagara Falls in North America was the world's first large power plant. The 5000 hp turbine wheels were manufactured in America because of import duties, but their governors were supplied from Switzerland.

Piccard-Pictet & Cie

Lucien Pictet joined the company in 1893 . Pictet graduated from Zurich and previously worked at Escher Wyss and ACMV . With Faesch's death in 1895, Pictet became a partner in the company, which from then on was called Société en nom collectif Piccard & Pictet . In 1898 it was converted into a limited partnership and was called Société en commandite Piccard, Pictet & Cie. In the same year, the company moved to new premises in Charmilles on Route de Lyon 109 because the old one had become too small.

In 1906 the company became a public limited company with the name Ateliers Piccard-Pictet & Cie. transformed. In the same year, the company started manufacturing automobiles on behalf of the Société des Automobiles à Genève (SAG), which was founded by Lucien Pictet alone in 1904 , with only the chassis being supplied with the engine and the customer having to do the bodywork himself common practice at the time. The chassis was designed by Marc Birkigt , the chief designer at Hispano-Suiza , and production was carried out under his license . From 1907 to 1909 only 165 chassis were produced, which did not generate enough returns for SAG, so that the company became insolvent. It was therefore taken over by Ateliers Piccard-Pictet & Cie., The main creditor. The production of the chassis has now continued under the Pic-Pic brand . During the First World War , chassis were only built for the Swiss Army , but garnet detonators were made for the Entente cordiale .

Franco-Swiss industrial group

The ambitious plan of a large French-Swiss industrial group was to be financed with the capital generated during the war and the support of banks. This should be active in the energy as well as in the transport sector and its main task was to build up the car production. The investors were numerous. These were the coal mines of Dorénaz and Semsales , the power plant in Bex , the Foundry Rosario in Geneva, vehicle mechanic SIMAR (manufacturer of rotary tillers ), Gangloff (bodies), Motosachoche (motorcycles) and Martini (cars), the electric company Sécheron and BBC , as well as the mechanical engineering companies SIP (machine tools) and ACMV .

The two architects Revilliod and Turettini were commissioned to build the halls for a new car factory, which should be able to produce 1500 vehicles per year. On the basis of an oral contract, a central warehouse, a large workshop, a hardening shop and a two-story assembly hall for the chassis were built. For the turbine construction, the area of the assembly hall was tripled, the height doubled and hall cranes were provided. The foundry was also enlarged and furnished with new equipment. A network of meter gauge tracks was laid for internal transport .

After the First World War

The automobile factory was completed less than two months after the end of the war. Piccard & Pictet recognized that in terms of price they could not keep up with the low-cost standard products of the auto industry in America, Great Britain and France, which is why they switched to the segment of expensive luxury cars, which had no longer been served during the war years. Due to its good reputation, the company managed to get 2,800 orders from France alone in a short time. The level of awareness of Pic-Pic was further increased through participation in a future-oriented project for a workers' garden city . While parts were still being manufactured for Rolls-Royce in the summer of 1918 , the company's management launched its first own series of 500 pic-pic cars in March 1919. The four-cylinder engine vehicles should be built within six months.

The parts for the cars were almost all manufactured in-house, so that there was no need for suppliers . It was a big park of Oerlikon -machine tools and Citroën -Verzahnungsmaschinen available with which the then new herringbone the smooth-running gear wheels could be made. Even if the production was not completely Taylorized , as was the case with Ford , industrial series production was introduced, which should produce larger quantities in a shorter time than the manufacture before the war. The individual assemblies such as frames, gears, suspension and brakes were preassembled and brought to the temporary storage facility in the basement of the car assembly hall . The chassis were built on a total of three assembly lines on the ground floor and first floor of the hall. Those intended to be fitted with standard bodies were taken to the second floor, where Gangloff- trained staff built the bodies. The cladding panels for the structure were also cut and preformed in-house. Then the cars were driven for commissioning and cleaning. It took more than 1000 hours to assemble a car; it took just 160 hours to assemble a Ford in 1923.

When the first chassis rolled out of the production line, problems arose in engine production. The vehicles were to be equipped with particularly quiet, valveless slide motors based on a patent from Argyll Motors improved by Pic-Pic . Even if the goal in terms of noise was achieved, there was no experience of manufacturing such engines. The concentric tubes sliding on top of each other, which took on the function of the inlet and outlet valves, had to be manufactured to the hundredth of a millimeter, otherwise the engine would leak or be destroyed. In order not to lose face, the management put the blame for the misery on the poor quality of the American steels and at the same time ordered the employees to be retrained. The production backlog grew bigger and bigger. In May 1920, 15 months after production started, only 100 chassis had left the factory. Although the unreliable valve motor was abandoned, the damage was already done. The customers were alarmed and withdrew from the contracts. The vehicles found no more buyers and could only be sold at discount prices that were 60 to 70% below the prime costs.

After the financial crisis of 1919 , the company became insolvent in December 1920, leaving 1,500 workers and 300 employees unemployed. A mountain of debt of 23.4 million francs remained, which was made up as follows: 7.4 million deficit of the car factory, 8 million from the enlargement of the plant and 8 million from investments in other companies, about which the board of directors often knew nothing.

Successor companies

The Swiss Bank Corporation and the Comptoir national d'etescompte de Paris , a forerunner of BNP Paribas , were the main creditors of the insolvent Ateliers Piccard-Pictet & Cie. In order to save the capital tied up in the factory and the employees, they had no choice but to found a new company. As a result, the Ateliers des Charmilles SA came into being in 1921 under the direction of René Neeser, which continued to carry out general mechanical engineering and the construction of water turbines.

In cooperation with the engine manufacturer Gnome & Rhône , the construction of pic-pic automobiles was to be relaunched. A few cars were built. In 1922 a prototype with an eight-cylinder engine and 6 liter displacement appeared, which was exhibited for the last time at the Geneva Motor Show in 1924 before production closed forever in the same year.

Preserved buildings

The car assembly hall was no longer used by the Ateliers des Charmilles after the vehicle construction was discontinued and was rented to external companies. These included the Tavaro fuse factory , which later became known for the ELNA sewing machines and which used the building until 1995. After that, it stood empty for about 15 years until the premises of the factory were converted into loft apartments and two additional upper floors were added to the factory. The change of use was related to the redesign of the area freed by the demolition of the Stade des Charmilles . The building is under heritage protection due to its architecture, which is typical for industrial buildings of the early 20th century.

![]()

Web links

- Jean de Senarclens: Piccard-Pictet & Cie .. In: Historisches Lexikon der Schweiz .

- Fondation des Archives de la Famille Pictet. (French).

Individual evidence

- ^ A b Jean de Senarclens: Piccard-Pictet & Cie .. In: Historisches Lexikon der Schweiz . May 18, 2010 .

- ↑ a b c Un industriel au cœur de l'Europe. Lettres à sa famille 1857-1886 . Editions d'en bas, 2008, ISBN 978-2-8290-0356-1 ( limited preview in Google book search).

- ^ Catalog for the Swiss department of the Vienna World Exhibition 1873. In: Internet Archive. Retrieved May 17, 2015 .

- ↑ Martin Zogg: History of the heat pump . Swiss contributions and international milestones. Ed .: DETEC . 2008, ISBN 978-3-03302154-9 , pp. 17–19 ( pulledg-engineering.ch [PDF; 8.5 MB ]).

- ^ A. van Muyden: Les turbines Faesch et Piccard à Niagarafalls . In: Bulletin de la Société vaudoise des ingénieurs et des architectes . Volume 21, No. 8 , 1895, p. 247-249 , doi : 10.5169 / seals-18769 .

- ↑ Thomas Gull: Five Things We Should Know About World War I. University of Zurich, September 2, 2014 .

- ↑ Nouvelles turbines installées par la Société anonyme des Ateliers Piccard, Pictet & Cie de Genève, à l'usine de Spiez, en vue de la traction électrique sur la ligne du Loetschberg (partie 1) . In: Bulletin technique de la Suisse romande . tape 37 , issue 12, June 25, 1911, p. 134 , doi : 10.5169 / seals-28851 .

- ↑ a b c d e f g h i Bénédict Frommel: L'usine Tavaro. (PDF) Etat de Genève - L'Office du Patrimoine et des sites, September 2002 (French).

- ^ Jean de Senarclens: Charmilles Technologies. In: Historical Lexicon of Switzerland .

- ^ Piccard-Pictet. In: Auto 1/43. 2010, accessed September 30, 2018 .

- ↑ Bénédict Frommel: Tavaro. In: Historical Lexicon of Switzerland .

- ^ Immeuble Pic-Pic. In: Architectes.ch. Retrieved October 2, 2018 .