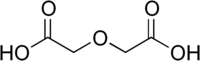

Diglycolic acid

| Structural formula | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||

| General | ||||||||||||||||

| Surname | Diglycolic acid | |||||||||||||||

| other names |

|

|||||||||||||||

| Molecular formula | C 4 H 6 O 5 | |||||||||||||||

| Brief description |

white or light yellow odorless flakes or crystalline powder |

|||||||||||||||

| External identifiers / databases | ||||||||||||||||

|

||||||||||||||||

| properties | ||||||||||||||||

| Molar mass | 134.09 g mol −1 | |||||||||||||||

| Physical state |

firmly |

|||||||||||||||

| Melting point | ||||||||||||||||

| pK s value |

|

|||||||||||||||

| solubility |

very soluble in water (417 g l −1 ), in water at 0 ° C (209 g l −1 ), in water at 25 ° C (715 g l −1 ), soluble in ethanol , slightly soluble in diethyl ether |

|||||||||||||||

| safety instructions | ||||||||||||||||

|

||||||||||||||||

| Toxicological data | ||||||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | ||||||||||||||||

Diglycolic acid is an aliphatic dicarboxylic acid or the simplest oxadioic acid, the acidity of which is between that of acetic acid and oxalic acid . It arises from the oxidation of diethylene glycol DEG in the organism and can lead to serious complications with fatal outcome.

Manufacturing

As early as the 1860s, A. Wurtz described the production of diglycolic acid by oxidizing diethylene glycol with concentrated nitric acid .

At the same time, W. Heintz reported the synthesis from monochloroacetic acid by heating with sodium hydroxide solution .

In a variant with barium hydroxide solution as the alkaline medium, diglycolic acid is obtained in 68% yield after acidification.

The yields of the reactions described are unsatisfactory for use on an industrial scale. Even in the presence of an oxidation catalyst ( vanadium (V) oxide ) , the single-stage nitric acid process only yields diglycolic acid yields of 58–60%. In a multi-stage process of nitric acid oxidation at 70 ° C. and repeated crystallization, evaporation of the supernatants and recycling of the DEG-containing mother liquor, product yields of up to 99% (based on DEG) can be achieved.

The oxidation of DEG with air, oxygen or ozone avoids the use of expensive nitric acid and the inevitable formation of nitrous gases . In the presence of a platinum catalyst, yields of 90% can be obtained in the air oxidation of DEG.

With a bismuth- platinum contact, yields of 95% should be achieved under optimized reaction conditions.

The oxidation of 1,4-dioxan-2-one (p-dioxanone), a lactone used as a comonomer in biodegradable polyesters, with nitric acid or dinitrogen tetroxide with yields of up to 75% is also described in a patent.

properties

Diglycolic acid is very soluble in water and crystallizes from water in monoclinic prisms as a white, odorless solid. The monohydrate is formed at a humidity above 72% and 25 ° C. The commercial product is the anhydrous form as free flowing scales.

Applications

Diesters of diglycolic acid with (branched) higher alcohols can be used as plasticizers for polyvinyl chloride (PVC) with properties comparable to di- n -octyl phthalate (DOP).

Basic solutions of diglycolic acid are described for the removal of limescale deposits in gas and oil wells, as well as in system parts such as heat exchangers or steam boilers.

Diglycolic acid can function as a diester component in homo- and copolymeric polyesters , so-called polyalkylene diglycolates,

which are biocompatible and biodegradable and can be used alone or in blends with aliphatic polyesters as tissue glue, cartilage replacement or as implant material.

Individual evidence

- ↑ a b c Data sheet diglycolic acid for synthesis (PDF) from Merck , accessed on March 1, 2015.

- ↑ a b c d e data sheet diglycolic acid from Sigma-Aldrich , accessed on March 1, 2015 ( PDF ).

- ↑ a b c d e f g h W.M. Bruner, LT Sherwood, Jr .: Diglycolic acid - a new commercial dibasic acid . In: Ind. Eng. Chem. Band 41 , no. 8 , 1949, pp. 1653-1656 , doi : 10.1021 / ie50476a032 .

- ↑ L. Bhattacharyya, J. Rohrer (Ed.): Appendix 1: DISSOCIATION CONSTANTS (pKa) OF ORGANIC ACIDS (AT 20 ° C), in Applications of Ion Chromatography for Pharmaceutical and Biological Products . John Wiley & Sons, Inc., 2012, doi : 10.1002 / 9781118147009.app1 .

- ↑ AA Roscher, E. Jussek, T. Noguchi, S. Franklin: Fatal Accidental Diglycolic Acid poisoning . In: Bull. Soc. Pharm. Environ. Pathol. tape III , no. 4 , 1975 ( PDF ). PDF ( Memento of the original from June 29, 2017 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ^ A. Wurtz: Conversion of Ethylene to Complex Organic Acids . In: Liebigs Ann. Chem. Band 117 , no. 1 , 1861, p. 136-140 , doi : 10.1002 / jlac.18611170114 .

- ↑ W. Heintz: About diglycolic acid (para malic acid) . In: Ann. Phys. tape 191 , no. 2 , 1862, p. 280-295 , doi : 10.1002 / andp.18621910206 .

- ↑ KE Füger: Synthesis and catalytic reduction of glycolic acid and glycolic acid esters, doctoral thesis ETH Zurich . Juris-Verlag, 1959 ( PDF ).

- ↑ C. Erk: Condensation of diglycolic acid dichloride with polyglycols, 5. An improved synthesis of cyclic polyether-esters by cyclization . In: Liebigs Ann. Chem. Band 10 , 1991, pp. 1083-1084 , doi : 10.1002 / jlac.1991199101186 .

- ↑ Patent US4066691 : Process for the production of pure diglycolic acid by oxidation if diethylene glycol with nitric acid. Registered on September 8, 1976 , published on January 3, 1978 , applicant: Chemische Werke Hüls AG, inventor: M. Schröder.

- ↑ Patent US3879452 : Method for making diglycolic acid, dipropionic acid and the salts thereof. Filed on June 18, 1971 , published on April 22, 1975 , Applicant: Conen Corp., Inventor: GE Brown, Jr

- ↑ Patent US4256916A : Oxidation of polyethylene glycols to dicarboxylic acids. Filed August 15, 1979 , published March 17, 1981 , Applicant: Eastman Kodak Co., Inventor: DL Morris, WJ Gammans, JD Holmes.

- ↑ YY. Zhang, Z.-Y. Liang, Y.-D. Zhang: Preparation of Diglycolic Acid via Oxidation of Diethylene Glycol with Molecular Oxygen . In: Fine Chemicals . May 2012 ( PDF ).

- ↑ Patent US3952054 : Process for preparing diglycolic acid. Applied December 5, 1974 , published April 20, 1976 , applicant: Monsanto Co., inventor: CY Shen.

- ↑ Patent US3173888 : Diesters of diglycolic acid and vinyl chloride polymers plastized therewith. Applied on November 13, 1962 , published March 16, 1965 , Applicant: Eastman Kodak Co., Inventors: PT von Bramer, RM Simons.

- ↑ Patent US3639279 : Scale removal composition and method using salt of diglycolic acid and base at pH above 5. Applied April 1, 1969 , published February 1, 1972 , Applicant: Halliburton Co., Inventor: TR Gardner, RM Lasater, JA Knox.

- ↑ Patent US5696178 : Absorbable polyalkylene diglycolates. Filed July 22, 1996 , published December 9, 1997 , Applicants: Ethicon, Inc., Inventors: K. Cooper, A. Scopelianos.