Assembly line production

The assembly line manufacturing (or production line ) is a Fertigungsablaufart applied in the industrial production of bulk goods. It represents a specialization of flow production in which the products are transported individually, often continuously, from one workstation to the next for further processing.

Flow production

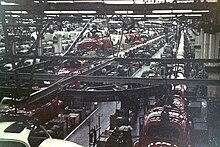

In flow production (or series production ), the production of a product is divided into successive work processes, which in turn can be divided into individual work steps. The installation of the equipment follows this production process, the machines and tools are arranged at the workplace as required by the sequence of the work process. The best-known example of assembly line production are the assembly lines in automobile construction, which are divided into assembly cycles.

The assembly line production is a further development or specialization of the assembly line production. In this case, the equipment or workplaces are also arranged in a row as it corresponds to the work sequence. In flow production, however, the promotion is still carried out in batches . In both concepts, the work steps are predetermined in time. In the case of assembly line production, the prescribed "cycle time" must be observed if there is a fixed linkage.

The planning and implementation of the production is based on the product (workpiece), i.e. according to the object principle .

Flow production

A floating production is mostly procedural reasons. The arrangement of the production points is an inevitable consequence of technological conditions of the production process, for example in the processing of crude oil in refineries or in steel production or organizational considerations.

Assembly line production

In assembly line production, the most consistent form of assembly line production, the material is transported between the individual production points with the help of linked conveyor systems ( e.g. conveyor belts ) in batches of one. The individual work steps are usually reduced to a few simple steps. In the classic form, a work step is a permanent repetition of a precisely determined sequence of actions.

The work processes to be carried out and the transport between the production sites are carried out at a fixed time. This means that the processing time at the individual stations depends on one another. One speaks of a time-bound flow production .

An optimal assembly line adjustment is decisive for the smooth process :

The individual work steps and workstations must be defined in such a way that their implementation requires exactly a defined period of time, the cycle time . By specifying a fixed production process, scheduling and capacity planning problems can be efficiently solved, the most productive manufacturing process is enforced, so to speak.

If the production points are automatically linked, one speaks of a (rigid) transfer line , the production process is fully automatic.

Due to the often high system intensity , this type of production is mainly used in variety and mass production . Due to the low flexibility - the product structure must not be subject to short-term changes - a reliable market analysis is also required.

In return, the variable costs can be kept relatively low (low costs of storage and transport, manufacturing and wages, little scrap and waste).

Assembly line production is used, for example, in automobile production , the publishing and printing industry and the food industry.

advantages

- Semi-finished products are reduced to a minimum, thereby, intermediate storage are avoided largely.

- The consistent arrangement of the workstations also saves space, and transport routes are shortened and transport costs are reduced

- (Cost) advantages through division of labor and specialization

- Short lead times enable a reduction in the overall production time

disadvantage

- Little flexibility in the event of fluctuations in employment, the adaptability of the company is reduced

- high failure susceptibility of the entire production in the event of machine or work failures

- high system intensity

- often little room for maneuver of the workforce

- monotonous work creates alienation , numbness and motivational problems

- Inadequate communication opportunities create social problems for workers

history

Already in the late 15th century ships were being manufactured like assembly lines in the Arsenale Novissimo in Venice . In 1790 Oliver Evans received a patent for a mill using various continuous transport techniques. In 1833, an assembly line was introduced for the production of ship biscuits in England. Around the year 1870 were in the slaughterhouses of Cincinnati upswept conveyor belts used to transport the pigs slaughtered by a worker to the next. This technique was perfected and used on a large scale in Chicago's Union Stock Yards . The so-called "disassembly lines" were also a model for the "assembly lines" for the production of the Ford T .

In Germany, the Bahlsen company started using the assembly line as early as 1905.

As early as 1902, Ransom Eli Olds used movable wooden frames (wheeled carts) for the production of his " Oldsmobile ", on which the frames were pushed from station to station. Henry Ford mechanized and refined this principle by building a permanent assembly line with the help of his engineer Charles E. Sorensen and the foreman Lewis in 1913, thus installing the first “moving assembly line”. As a result, Ford increased production eightfold, so that at the same time he was able to enormously reduce the price of his T-model (known as " Tin Lizzy " or "Blechliesel") and increase wages.

Due to his success, he built a brand new factory on the River Rouge in Detroit based on this principle, which became a Mecca for engineers and automobile manufacturers from all over the world. Many of them then adopted Henry Ford's production principles such as Fiat , Renault or Volvo . In Germany, assembly line production in automobile construction was first introduced in the 1920s by the Adam Opel company with the “ tree frog ” and by the Hanomag company with the “ commissary bread ”. The Daimler factories only introduced this type of production organization in the 1930s through Wilhelm Friedle , who was the operations director of Daimler-Benz AG at the Sindelfingen plant . The Volkswagen plant in Wolfsburg, where the KdF car was to be built, was also designed in the 1930s based on the model of the Ford factory on the River Rouge.

Assembly line production is still current in the automotive industry, and the flow principle is constantly being expanded. One example of this is just-in-time production , in which flow production is extended to the supplier and sometimes even to the sub-supplier . A number of companies in other branches of industry, such as the aircraft industry (e.g. Boeing ) and mechanical engineering ( e.g. Gildemeister , Trumpf ), are increasingly converting their production to flow production. The flow production is one of the essential principles the introduction of the pull system and various methods and techniques of production planning and control , such as the method of the cumulative quantity or Kanban .

The initial welcome of the assembly line, which was celebrated as revolutionary, soon turned into strong rejection. The mechanical work processes to which the workers were exposed led to a dulling and devaluation of the workforce, since only a few, monotonous movements of the individual were necessary.

The so-called humanization of the world of work led to a change in the process management of assembly line work. The work steps are carried out in groups ( group work / group production ) and the piecework (work performance) relates to a group of workers (working people, industrial employees).

The actor Charlie Chaplin has to work in his assembly line film " Modern Times (" Modern Times ) shown impressive.

See also

- Assembly line voting

- Chaku-Chaku

- Production line

- Production line

- Heijunka

- Heikinka

- Versatile production systems

- Leveling

- Serial production

- Taylorism

- Stone cooler break

- Jumper (clockwork)

literature

- Henry Ford: Success in Life - My Life and Work . List Verlag, Munich 1952.

- Helen Jones Earley, James R. Walkinshaw: Setting the Pace - Oldsmobile's first 100 Years . Oldsmobil Division of GM Verlag, Lansing 1996, ISBN 0-7853-1958-1 .

- Wolfgang Domschke, Armin Scholl, Stefan Voss : Production planning . 2nd Edition. Springer-Verlag, Berlin 2005, ISBN 3-540-63560-2 .

- Russ Banham: The Ford Century . Tehabi Books, San Diego 2002, ISBN 1-887656-91-X .

- Wilmjakob Herlyn: PPS in automotive engineering - production program planning and control of vehicles and assemblies . Hanser Verlag, Munich 2012, ISBN 978-3-446-41370-2 .

- Wolfgang Holle: Computer-aided assembly planning - assembly planning and simultaneous engineering . Hanser Verlag, Munich 2002, ISBN 3-446-21986-2 .

- David E. Nye : America's Assembly Line . MIT Press, Cambridge / London 2013, ISBN 978-0-262-01871-5 .

- Mario Steinbrink: Transition to flow work and assembly line production in the "Gebr. Reichstein Brennabor-Werke Brandenburg / Havel", VFV-Info 2/2016

Web links

Individual evidence

- ↑ The invention of the battle plan. ( Page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. (PDF; 2.2 MB) - The history of the Union Stock Yards at brand eins

- ↑ The Bahlsen Chronicle ( Memento from August 5, 2013 in the Internet Archive )

- ^ HJ Earley, JR Walkinshaw: Setting the Pace. Lansing 1996, ISBN 0-7853-1958-1 , p. 37.

- ^ Henry Ford: Success in Life. Paul List Verlag, Munich 1952, p. 48 ff.

- ↑ Banham: The Ford Century. Tehabi books, San Diego 2002, ISBN 1-887656-91-X , p. 37 ff.

- ^ Henry Ford: Success in Life. Paul List Verlag, Munich 1952, p. 94 ff.

- ↑ Herlyn: PPS in the automotive industry. Hanser Verlag, Munich 2012, ISBN 978-3-446-41370-2 , p. 24 ff.

- ↑ Herlyn: PPS in the automotive industry. Hanser Verlag, Munich 2012, ISBN 978-3-446-41370-2 , pp. 34-46.