H12MDI

| Structural formula | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||

| General | ||||||||||||||||

| Surname | H12MDI | |||||||||||||||

| other names |

|

|||||||||||||||

| Molecular formula | C 15 H 22 N 2 O 2 | |||||||||||||||

| Brief description |

colorless liquid |

|||||||||||||||

| External identifiers / databases | ||||||||||||||||

|

||||||||||||||||

| properties | ||||||||||||||||

| Molar mass | 262.35 g mol −1 | |||||||||||||||

| Physical state |

liquid |

|||||||||||||||

| density |

1.07 g cm −3 |

|||||||||||||||

| Melting point |

25 ° C (beginning of crystallization) |

|||||||||||||||

| Vapor pressure |

2.1 mPa (25 ° C) |

|||||||||||||||

| solubility |

practically insoluble in water, hydrolysis |

|||||||||||||||

| safety instructions | ||||||||||||||||

|

||||||||||||||||

| MAK |

0.054 mg m −3 |

|||||||||||||||

| Toxicological data | ||||||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | ||||||||||||||||

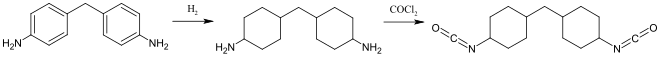

H12MDI , also H 12 MDI , is an aliphatic diisocyanate and an important raw material for high-quality polyurethane resins . The systematic name is rarely used. The short form means 12-fold hydrogenated MDI and indicates the origin of the analogous aromatic .

Properties and uses

The methylene group is equatorially bound to both cyclic rings in the chair conformation , the isocyanate groups bound in the 4,4'-position are present both axially (Z) and equatorially (E), so H12MDI consists of a mixture of the three possible conformational isomers with respect to the isocyanate groups . Polyurethanes based on H12MDI are therefore much less prone to crystallization than analogous compounds made from MDI.

As a cycloaliphatic isocyanate, H12MDI is particularly suitable with suitable reaction partners for products of high transparency and lightfastness. In addition, the materials are extremely resistant to hydrolysis . H12MDI can therefore be used to produce resins for optical applications and high-quality paints and coatings. The isocyanate groups are sterically and electronically decoupled from one another so that, in contrast to other diisocyanates, they have approximately the same reactivity in the course of a chain extension. Since the reaction with water is relatively slow, H12MDI is particularly suitable for the production of polyurethane dispersions in the melt dispersion process , in which the side reaction of isocyanate with water can be better controlled.

Manufacturing

MDA (methylenediphenyl-4,4'-diamine) is completely hydrogenated to methylenedicyclohexyl-4,4'-diamine and then converted into the diisocyanate with phosgene .

Alternatively, the urea route is also used. Well-known manufacturers are Covestro (Desmodur ® W) and Evonik (Vestanat ® H 12 MDI).

safety

H12MDI can cause sensitization and must be handled with appropriate precautionary measures. The inhalation toxicity is very high.

Individual evidence

- ↑ Data sheet Dicyclohexylmethane 4,4′-diisocyanate, mixture of isomers, tech. 90% at AlfaAesar, accessed April 1, 2010 ( PDF )(JavaScript required) .

- ↑ a b c Entry on Methylene-bis (4-cyclohexylisocyanate) at ChemBlink , accessed on February 25, 2011.

- ↑ a b Covestro manufacturer's information on Desmodur W ( Memento of May 8, 2018 in the Internet Archive ), accessed on May 7, 2018.

- ↑ a b Entry on 4,4'-methylenedicyclohexyl diisocyanate in the GESTIS substance database of the IFA , accessed on January 8, 2020(JavaScript required) .

- ↑ Entry on 4,4′-methylenedicyclohexyl diisocyanate in the Classification and Labeling Inventory of the European Chemicals Agency (ECHA), accessed on February 1, 2016. Manufacturers or distributors can expand the harmonized classification and labeling .

- ↑ Roth: Safety data, MAK values . ecomed verlagsgesellschaft, Landsberg issue 10/02

- ^ National Technical Information Service. Vol. OTS000555173.

- ^ National Technical Information Service. Vol. OTS0534736.

- ↑ Documentation of the Threshold Limit Values and Biological Exposure Indices, 5th Edition, Cincinnati, American Conference of Governmental Industrial Hygienists, Vol. 6, p. 998, 1991.

- ^ Ulrich Meier-Westhues: Polyurethanes: Paints, adhesives and sealants . 2nd Edition. Vincentz Network, Hannover 2007, ISBN 3-86630-896-5 , p. 25.