Kenaf

| Kenaf | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

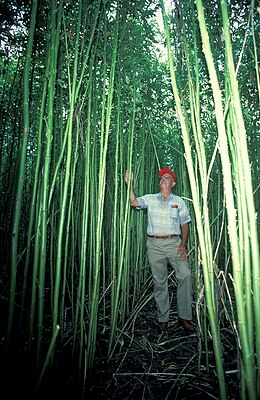

Kenaf plant |

||||||||||||

| Systematics | ||||||||||||

|

||||||||||||

| Scientific name | ||||||||||||

| Hibiscus cannabinus | ||||||||||||

| L. |

Kenaf ( Hibiscus cannabinus ) is a tropical to subtropical plant from the mallow family , which is grown to obtain the fibers and oil of the same name.

features

Kenaf has a tap root . In close proximity, the plant grows unbranched three to four meters high. The stems are wire-haired and spiky-bristled. Depending on the variety, they are green or reddish to purple. The leaves are long-stalked and softly hairy. The nickname cannabinus (hemp-like) can be traced back to the similarity of the leaf shape with that of the hemp . Depending on the variety, they are palmately lobed to entire.

The flowers sit individually in the upper leaf axils. They are large, white to yellowish with a dark red spot on the base. The flowers open before sunrise and wither by noon on the same day. Self-fertilization predominates . The fruit capsules are angular and finely hairy. They are surrounded by the hardened, prickly sepals. When ripe, the capsules pop open with five flaps and release the 5 × 3 millimeter seeds. These are gray-black and wedge-shaped-edged. They contain 15% to 20% of a semi-drying oil.

The fiber content of the bark is lower in the flower-bearing part than in the lower part. It is between 2.5% and 5%. The individual fibers are 1.5 to 11 millimeters long (mean 2.4 millimeters), with a diameter of 12 to 36 micrometers (mean 20 micrometers).

Kenaf is diploid with a chromosome number of 2n = 36.

Occurrence

Kenaf comes from the Afro-Asian region, is not frost-hardy and is therefore only annual in Central Europe. However, without frost, the plant can also be perennial. The main growing areas are in India , China and Southeast Asia.

Cultivation

The most favorable conditions are at a temperature between 15 ° C and 27 ° C, so that the potential cultivation area lies between 45 ° north and 30 ° south latitude. During the growing season, between 500 and 700 mm of precipitation should fall in 2.5 to 4.5 months. Sandy loams and loam soils with pH values between 5 and 7 are ideal. During dry periods, the groundwater is sufficient provided it is not deeper than 1.5 meters, otherwise irrigation is necessary. A sufficient supply of phosphorus and potassium is necessary for fiber formation . Recommended is: phosphate 60 kg / hectare, potassium 120 kg / hectare, nitrogen first dose 20 to 30 kg / hectare, second dose 50 to 60 kg / hectare. Care is usually only necessary in the first three weeks after sowing. The growing season is 70 to 140 days.

If grown inappropriately , kenaf is sensitive to root rot and anthracnose ( Colletotrichum hibisci ). During the growth of one ton of kenaf binds about 1.5 tons of CO 2 and thus has one of the highest CO 2 - adsorption rates at all within the plant world.

The harvest takes place after the first five to ten flowers appear. Immediately after mowing, the kenaf is debarked. The roasting takes at water temperatures above 24 ° C eight to 12 days.

Cultivation in Central Europe

Kenaf has higher heat requirements than maize , thrives best on medium-heavy weed- free soils and is somewhat sensitive to summer drought. It reaches a height of 3.5 to 4 m in four to five months. Usable parts of the plant are the stems, which - similar to hemp - divide into long fibers and shives (with short fibers ). The total yield is around 8 t / ha with a fiber content of 20%. Due to the high climatic demands, however, kenaf can only be given little chance in Germany.

Kenaf is sown in Central Europe from mid-May to early June. The seed rate is 35 to 40 germinable seeds per m 2 , the sowing depth is 3–4 cm. For mechanical weed control, a row spacing of 40–50 cm must be maintained. The soil temperature required for germination is 12 ° C, a temperature of at least 16 ° C is required for growth. Germination is fast, but youth development is slow, elongated growth begins at the end of July and beginning of August. Because of the high temperature requirements, kenaf is not very competitive and relies on efficient weed control. Weeds are to be combated in the germinating to 2-leaf stage, mechanical control is possible from a kenaf plant height of 15 cm. In favorable locations and in good years, an application of 30 kg N per hectare appears to be sufficient on soils with good N mineralization. The most important disease is gray mold rot ( Botrytis cinerea ).

Production numbers

| region | Quantity ( 1,000 t ) |

rank | country | Quantity (1,000 t) |

|

|---|---|---|---|---|---|

| world | 341.12 | 1 |

|

139.70 | |

| Asia | 279.15 | 2 |

|

86.80 | |

| Latin America and the Caribbean | 38.08 | 3 |

|

36.00 | |

| Africa | 13.19 | 4th |

|

26.10 | |

| middle East | 3.70 | 5 |

|

10.50 | |

| Developing countries | 334.12 | 6th |

|

10.00 | |

| Industrialized countries | 7.00 | 7th |

|

4.00 | |

| 8th |

|

1.50 | |||

| 9 |

|

0.65 |

There are no explicit figures on the global production of kenaf. The FAO lists kenaf together with other jute-like fiber plants in the category "Kenaf and allied fibers" (kenaf and similar fibers). The jute-like fiber plants in use include z. B. Roselle . The adjacent table shows the global production of fibers in the FAO category “Kenaf and allied fibers” for the 2007/08 marketing year.

use

Kenaf fiber

If kenaf is grown for fiber use, the fiber yields are between 1.8 and 2.5 tons per hectare, in the best case 3.5 tons per hectare. The fiber is obtained from the bast of the stem, therefore the kenaf fiber belongs to the group of bast fibers . The fibers are similar to those of jute , but contain about 5% less lignin , which makes them less sensitive to light. The kenaf fiber consists of 44-57% by weight cellulose , 15-19% by weight lignin, 22-23% by weight pentosans and 2-5% by weight ash .

Kenaf is traditionally used to make rope or sackcloth. Newer application possibilities are building materials as well as the use as adsorbent or as feed or bedding material for livestock. Kenaf is also grown to produce pulp for papermaking . The yield is around 20 tons of pulp per hectare. The leftovers from fiber cultivation are also used to produce pulp, or they are used as fuel.

Kenaf fibers can also be used as reinforcement fibers for natural fiber-reinforced plastics . Like many other natural fibers , kenaf has good mechanical properties with a low density. Since kenaf is grown commercially, the fibers are also economically interesting. One of the first products made with kenaf fiber is a cell phone case from NEC Corporation made of kenaf fiber reinforced PLA . PLA is a biopolymer , the kenaf-reinforced material is completely biodegradable . By adding the kenaf fibers to the plastic, an improvement in the heat resistance and rigidity could be achieved. Natural fiber composites can also be used in conjunction with polypropylene , which have excellent tensile and flexural properties.

A growing area of application for kenaf fibers is automobile construction; The pioneer here is the company Toyota , which first used kenaf for the interior door paneling in the Toyota Celsior model in 2000 and now uses kenaf for five different vehicle components (e.g. for seat backs) in 27 models, mainly in the luxury class. Kenaf fibers are also used to manufacture the fully electric BMW i3 .

Kenaf seeds

When growing for oil or seed production, the yields are 0.7 to 1.0 tons of seeds per hectare. The oil from the kenaf seeds is used for technical purposes, but also as food.

Web links

- Lexicon Renewable Resources Michael Pankratius.

- Technology Review - Down the wrong path to kenaf as an alternative to wood in papermaking.

- Purdue University link collection .

literature

- Gunther Franke (ed.): Useful plants of the tropics and subtropics. Volume 2: Special crop production. Ulmer, Stuttgart 1994, ISBN 3-8252-1768-X , pp. 354-359.

Individual evidence

- ↑ a b K. U. Heyland, H. Hanus, ER Keller: Oil fruits, fiber plants, medicinal plants and special crops. Eugen Ulmer KG, Stuttgart-Hohenheim, 2006, ISBN 3-8001-3203-6 , pp. 309-310.

- ↑ Michael Pankratius . Nachwachsende-Rohstoffe.biz - The future of the field, accessed on February 28, 2010.

- ↑ Amar K. Mohanty, Manjusri Misra, Lawrence T. Drzal, (Eds.): Natural fibers, biopolymers, and biocomposites. Taylor & Francis Group, Boca Raton, FL 2005, ISBN 0-8493-1741-X , p. 77.

- ↑ Fachagentur Nachwachsende Rohstoffe e. V. (FNR) 2008: Kenaf ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ^ A b E. Meister, V. Mediavilla, R. Vetter, M. Konermann: Examination of the cultivation and the possibilities of a market introduction of new fiber plants (hemp, kenaf, miscanthus) , final report June 1999. Cross-border institute for profitable, environmentally friendly land management ITADA , in cooperation with FAL Braunschweig and iful Müllheim / Baden online (PDF; 1.42 MB).

- ↑ a b FAO: Jute, Kenaf, Sisal, Abaca, Coir and Allied Fibers (PDF; 1.32 MB), on fao.org, accessed on January 22, 2017.

- ↑ Frederik T. Wallenberger and Norman Weston (eds.): Natural fibers, plastics and composites. Kluwer Academic Publishers, 2004, ISBN 1-4020-7643-6 , p. 159.

- ↑ NEC Announces Development of High-Strength Highly Heat Resistant Bioplastic - Featuring polylactic acid reinforced with kenaf fiber. NEC press release dated February 3, 2003.

- ↑ M. Zampaloni, F. Pourboghrat, SA Yankovich, BN Rodgers, J. Moore, LT Drzal, AK Mohanty, M. Misra: Kenaf natural fiber reinforced polypropylene composites: A discussion on manufacturing problems and solutions. In: Composites. Part A, Issue 38, 2007, pp. 1569–1580.

- ↑ Toyota Boshoku: Starting Full-scale Development of Kenaf Seeds for Automobile Interior Parts. Press release of May 14, 2008 online (PDF; 105 kB).