Machine element

Machine elements are components that are contained in technical structures in the same or at least similar form . The name refers to machines , but machine elements are also used in systems , apparatus , devices and modern structures . Their properties have been well researched. When designing and building technical structures, recurring individual tasks from the i. d. Usually elements graded according to size can be assumed.

The term element often refers to the smallest possible part. What is meant here, however, is the smallest possible and sensible organizational unit that is advantageous for the function and the division of labor into building technical structures. A bicycle chain , which is composed of the sub-elements bolts , sleeves and plates , is treated as a whole, as a machine element of a bicycle .

The most common machine elements are used to connect the main parts of a technical structure - which can themselves be more complex machine elements . A typical connecting element is the screw (with nut ).

Standard machine elements such as connecting elements and seals are standardized in almost all properties , so they can be manufactured separately and kept available in order to implement the economically favorable principle of replacement .

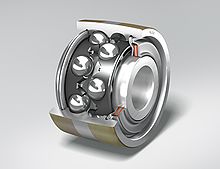

More complex machine elements are, for example, shafts , wheels , bearings , couplings and gears . The standardization is mostly limited to the shape and size of the connection surfaces to other parts. The principle of interchangeability based on the division of labor can still be used in some cases, for example with roller bearings .

structure

The classification of machine elements in manuals, tables or textbooks usually begins with the connecting elements . Due to the diversity of the machine elements, however, no uniform structure has been created so far. They are often dealt with in any order without any recognizable systematisation criterion. Textbooks occasionally reveal the main focus of their authors' work because some machine elements are only briefly covered or not covered at all.

Karl Kutzbach made a proposal for a fundamental systematization as early as 1927. It is based on the definition "that a machine is the application of all means for the regulated control of changes in location and shape of material or energy [or information]". Siegfried Hildebrand took it up in 1968 when structuring the precision mechanical components, which in principle apply to all machine elements.

The outline distinguishes work items from adjustment items . The work elements are divided into memory, lines and converters, “because every function value must be stored, forwarded and transformed. ... The adaptation elements are used to influence the work elements or to control and regulate. ... They are therefore divided into rest elements (resistors), switching elements and control and regulator elements. ”Rest elements have the task of creating or maintaining a state of rest. They are related to the guide elements, but only have to exclude individual degrees of freedom. Rest elements in the narrower sense are barriers and attacks . Special rest elements are clutches (locking between two shafts), brakes (variable resistance) and switches (maintaining and reaching preferred positions).

The following list contains connecting and machine elements:

- Work items

- Storage elements

-

Guide elements (lines)

- Plain bearings and roller bearings

- Axles and shafts

- Converter elements

- Customization elements

- Resting elements

- Switching elements

-

Control and regulator elements

- Brake regulator (e.g. centrifugal regulator )

- Escapement regulator (e.g. watch escapement )

- Other elements

literature

- K.-H. Decker, K. Kabus: Machine elements . 16th edition. Hanser, Munich 2007, ISBN 978-3-446-40897-5 .

- H. Haberhauer, F. Bodenstein: Machine elements . 14th edition. Springer, Berlin 2007, ISBN 978-3-540-34463-6 .

- Siegfried Hildebrand : Feinmechanische Bauelemente , Hanser, 1968

- Gustav Niemann , Hans Winter, Bernd-Robert Höhn: Machine elements . 4th edition. tape 1 : Construction and calculation of connections, bearings, shafts. Springer, Muenchen 2005, ISBN 978-3-540-25125-5 .

- Gustav Niemann, Hans Winter, B.-R. Höhn: machine elements . 2nd Edition. tape 2 : General gears, gear gears - basics, spur gears. Springer, Muenchen 2002, ISBN 978-3-540-11149-8 .

- Gustav Niemann, Burkhard Neumann, Hans Winter ,: machine elements . 2nd Edition. tape 3 : Helical, bevel, worm, chain, belt, friction gears, clutches, brakes, freewheels. Springer, Muenchen 2004, ISBN 978-3-540-10317-2 (first edition: 1983, reprint).

- H. Wittel, D. Jannasch, J. Voßiek, C. Spura: Roloff / Matek machine elements . 24th edition. Vieweg, Wiesbaden 2019, ISBN 978-3-658-26280-8 .

- Bertholt Schlecht: Machine elements 1: strength, shafts, connections, springs, couplings . 1st edition. Pearson Studium, Munich 2006, ISBN 978-3-8273-7145-4 .

- Bertholt Schlecht: Machine elements 2: gears, gears and bearings . 2nd Edition. Pearson Studies, Munich 2010, ISBN 978-3-8273-7146-1 .

Individual evidence

- ^ Karl Kutzbach: Systematics of the machine . In: Journal of the Association of German Engineers , Volume 71, 1927, p. 1200

- ^ Siegfried Hildebrand: Feinmechanische Bauelemente . Hanser, 1968.

- ^ Siegfried Hildebrand: Feinmechanische Bauelemente . Hanser, 1968, p. 287

- ^ Siegfried Hildebrand: Feinmechanische Bauelemente . Hanser, 1968, pp. 667 and 668