Engine failure

An engine failure is the loss of functionality and necessary or desirable properties in a motor . The damage can be caused by the affected engine component itself, i.e. as primary damage, or by other, external components whose malfunction, malfunction or damage has a damaging effect on the actual damaged part. The reasons for a malfunction depend on a large number of physical, chemical and electrochemical processes, which are summarized in VDI guideline 3822.

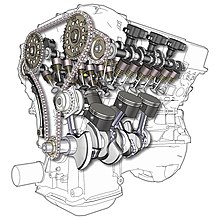

Internal combustion engines

The engine has compared to the electric motor on a number of disadvantages in terms of reliability. The multitude of mechanical elements and their interaction under the most varied of environmental conditions increase the probability of failure. The oscillating kinematics of the crankshaft drive in reciprocating piston engines is also critical , since the lubricating films formed break down at the piston dead centers and thus tribological disadvantages arise. The costs incurred in the oscillation inertial forces also necessitate high dynamic loads on the components leading to violence and fatigue fracture and also to unfavorable lubrication conditions in the camps run. Furthermore, aggressive media such as fuel and cooling water are fed to the engine due to the operation, which enable corrosion or otherwise attack the engine. During the combustion, further chemical compounds are formed, which put additional stress on the engine due to the high heat development, also by being transferred to the lubricating balance and thus reducing the quality of the lubricating oil .

Causes of damage

wear

In DIN 31 051 it says: [...] wear and tear is the price that has to be paid for using the system. No machine can be operated without wear [...] From this it follows that the wear and tear must be kept as low as possible in terms of construction and a certain amount of wear and tear must be available through the addition of material, the wear and tear of which does not affect operational safety. The unavoidable wear and its reworking is expressed in wear rates for the various components, which of course depend on the engine type and its use. For example , the following wear rate is given for large four-stroke engines operated with heavy fuel oil : 96% of all valves require slight regrinding after 5000–6000 operating hours.

Technical defects

Technical defects can generally be assigned to three cause groups.

Misinterpretation

The faulty construction of an engine is almost impossible to find today. Motors must be designed according to their purpose. Motors that are too weak are overloaded, while motors that are too strong work in uneconomical partial load operation, which also has a negative effect on the motor ( sooting , coking ). Internal combustion engines are manufactured almost exclusively with a crank drive and lift valves, controlled by a rotating camshaft, which work with two or four-stroke processes. There is extensive knowledge about these concepts from the development and operation of hundreds of millions of engines, which can be used during the development of an engine. Furthermore, engines are only manufactured by specialized manufacturers who in turn procure the necessary parts from companies that concentrate on certain areas within an engine. The modern calculation, computer simulation and measurement technology in the test help to exclude errors and to find and eliminate them at an early stage. The errors are mostly limited to small things that affect the choice of fits, materials and their heat treatment and the appropriate manufacturing process . Errors of this kind usually only become noticeable after a long to very long period of operation, since the causes of short-term errors are discovered during the experiment during the development phase.

Many malfunctions and damage result from planning errors in the entire machine system, as there are far more possibilities for errors and less knowledge. This applies less to passenger cars and commercial vehicles than engines for stationary operation, ships, trains and special vehicles. The manufacturers of such motors provide customers with extensive documentation so that they can solve problems independently if necessary. The planning of the maintenance work, i.e. its time interval and its implementation, often cause damage here. For example, a commercial vehicle was noticed in the damage statistics because its oil check was not carried out regularly, the oil filter clogged and the engine failed. The reason for this was that the oil dipstick was placed under the driver's seat, which made it annoying to check it.

Another possible design error in the broader sense can occur with improper engine tuning ; above all turbo and compressor , but to a limited extent also naturally aspirated engines can achieve the extra power achieved, e.g. B. by chip tuning , often not withstand in the long term if too little knowledge is available and the tuning is limited to individual engine components. A mere change of the boost pressure or the timing without further modifications that become necessary can, for. B. lead to significantly increased engine wear, burned-out engine seals and load damage to parts such as pistons, connecting rods, crankshaft and turbocharger or compressor.

Material defect

The wrong choice of material is no longer common today due to the broad knowledge base. Most of the time, there are material defects that can be traced back to the difficulty of producing perfect materials. The quality of a material fluctuates within a component, but this cannot be determined with justifiable effort. Defects in the material can occur at any time in the manufacturing process and extend to contaminated raw material, voids , inclusions, gas bubbles and segregation during casting, doubling during rolling , cracks and folds during forging, structural defects , heat treatment defects or bonding defects during coating .

There are no material defects if motors are operated outside of their factory specifications. This happens more often with the "unit designs" (500 cm³ per cylinder) of the diesel engines z. B. from BMW and Daimler-Benz by chip tuning measures the engines z. B. be brought from 180/184 HP to 220/224 HP - in the wrong belief that the engines are otherwise the same anyway. The pistons of the different performance levels are different and have different heat conduction capacities due to different alloys. With chip tuning and continuously high loads beyond its original specification, an engine is therefore very likely to get piston damage. This is not even recognizable in the spare parts lists: only one type of piston appears - that of the highest quality type. In new engines, however, up to three different, differently expensive and differently powerful piston types are installed depending on the power level.

Manufacturing defects

Possible manufacturing errors are non-compliance with dimensions, dimensional and shape tolerances , fits , surface properties ( hardness , roughness , waviness, etc.), mechanical surface damage (scratches, grooves, chatter marks). When assembling the individual parts, typical errors are misalignments and concentricity deviations, incorrect preload on screw connections and errors in balancing and alignment. The cause of the damage is also to be found in goods on the gray market .

Operational error

overload

Overload is the stress on a motor beyond its capabilities and the damage it causes. Overloading occurs when the engine has to deliver more power than it was designed for or when the power has to be delivered under restrictive conditions such as high or low coolant and lubricant temperatures , moist and warm intake air or low air pressure. If too much torque is demanded from the engine, its speed drops and the temperature of the entire engine rises, in particular the highly loaded engine and valve control elements. In engines, overloading is always associated with an increase in temperature, since higher torques require higher gas pressures in the cylinder, which in turn are made possible by increased heat conversion. The reduced material strength combined with higher component loads results in more deforming parts, the play no longer guarantees the smooth running of the sliding partners, which also contributes to the increase in temperature due to increased friction. There is now a risk that the lubricating film will collapse and eat the sliding partners . The overload does not have to be imposed on the engine from the outside, i.e. by the operator; it can also result from irregularities in engine operation. Causes for this are cold starts , knocking combustion , too early start of injection and the like.

Operator error

For the safe and long-lasting operation of an engine, it is important to observe the operating guidelines prescribed by the manufacturers. Depending on the intended use of the engine, these are very brief, as is the case with modern passenger car engines, or they are very extensive, such as with ship engines. Until the 1990s, all engines were required to be run in by the customer with less power consumption. This was used to remove production-related roughness and to coordinate the geometric shape of the sliding partners, which applies in particular to the cylinder running surface and piston rings . Modern car engines today require such a short run-in that after the test runs (with external drive and fired) in the factory they have reached a state that does not require any further measures on the part of the customer. Many types of engines still require a longer run-in of up to 1000 km or 30 hours of operation. If this is not done, the engine tends to leak in the area of the piston rings. Burning rings, increased oil consumption and wear are the consequences; the parts may eat.

Although just car engines cold start ability is assumed a cold start the engine Provideth problems. If the oil pump delivers the still viscous oil at too high a pressure, the bypass valve on the oil filter opens . If the engine is often started cold and not run warm, coking will form on the spark plug , the valves and the annular grooves on the piston. The cold start also promotes the formation of cold sludge (product of lubricating oil, combustion residues and condensation) in the crankcase . Larger motors must always be preheated to around 40 ° C. In addition to the negative effects on the engine, this also has a negative impact on the environment, since there is only poor combustion and the catalytic converter does not yet work to its full extent.

Engines do not tolerate long idle times because the small amounts of fuel supplied lead to misfiring. The fuel condenses on the cylinder surfaces, washes off the oil film and is carried by the piston rings into the lubrication circuit. Uncombusted hydrocarbons also get into the exhaust pipe and the environment and make operation more difficult for an attached exhaust gas turbocharger . Deposits are formed on all components in contact with the medium, and the engine is noticeably contaminated. In extreme cases, the piston rings get stuck and the piston seizes .

A lack of operating materials or inferior quality lead to damage cases that the manufacturer can only partially get under control. The manufacturer can only ensure that the operator can intervene in good time by monitoring the operating materials as reliably as possible. However, much of the damage is caused by the poor quality of the operating materials.

External influences are also largely beyond the control of the manufacturer. Traffic accidents, inadequate air filters, poor or deforming foundations (especially in ship operations) or frozen cooling water should be mentioned here.

Engine damage

General

This part of the article looks at damage that occurs to heat engines that work with cylinder pistons. Other heat engines such as turbines or rotary piston engines (e.g. Wankel engines ) are not discussed.

Damage to the engine

The engine or the crank drive an engine includes all the parts directly in the transformation of gas pressures are in the cylinder first in a straight line and subsequently involved in a rotating movement. The tasks that are placed on this central assembly in piston engines and the stresses to which it is exposed are extremely extensive. From this point of view, it is understandable that most damage in the engine, disregarding the peripherals, occurs here. Pistons, piston rings and bearing surfaces in particular are exposed to enormous loads. The oscillating motion sequence of the piston makes it difficult for a stable lubricating film to form between the piston skirt and piston ring to the cylinder running surface and between the piston pin and the pin bore in the piston. The lubricating film regularly breaks down at the dead points , resulting in increased friction with all its accompanying phenomena (wear, seizure). The often jagged shape of the piston crown to support the mixture formation absorbs a lot of heat, but the piston rings can only give off heat to a limited extent. Especially in slot-controlled two-stroke engines, the piston heats up very strongly near the exhaust.

It becomes more difficult with the following points:

- Loss of compression

- Internal loss of operating materials ( cylinder head gasket defective, leads to oil spilling into the combustion chamber or loss of coolant or oil in the coolant)

- Valve train except timing / timing chain / toothed belt defect

The engine block can often remain installed up to this point ; the cylinder head must be removed.

Repairing the following problems becomes very costly:

- Valves hit piston / crooked / piston damaged (requires engine dismantling, disassembly, boring, new oversized pistons)

- Piston seizure (engine blockage due to friction welding )

- Housing crack (due to frozen cooling water)

- General great wear and tear (with diesel engines : at some point the auto-ignition temperature is no longer reached due to insufficient compression ; the car can no longer be started, especially in winter.)

- Oil losses with combustion (blue, black clouds of smoke, high oil consumption of more than two liters over 1,000 km)

With these latter problems, there are several options to consider depending on the value of the vehicle:

- Shutting down the vehicle due to the inefficiency of repairs

- Installation of a factory replacement engine

- Installation of a replacement engine by independent repair shops

- Installation of a used engine from the car recycler

- Complete overhaul of the engine

A complete overhaul requires an intact, crack-free engine block . The following work steps are necessary here (incomplete list):

- Remove the engine and completely disassemble it (special tools are sometimes required),

- If necessary, drill out the engine block to the next piston dimension, purchase a new oversize piston,

- Check oil system (pump, pressure valves if necessary) and replace if necessary,

- Check crankshaft bearings, if necessary grind crankshaft and install oversize bearings,

- Check connecting rod bearings, possibly relocate connecting rods

- Renew the cylinder head or, if necessary, recondition new valves, new guides and new hydraulic valve lifters,

- Check camshaft condition, replace if necessary,

- Check camshaft bearings, replace bearing bushes if necessary

- Assemble everything with new seals (seal set), adjust, check, where necessary with new expansion screws (connecting rod, cylinder head),

- Check the ignition system (play of the distributor shaft, sensors, control unit),

- Check flywheel , replace clutch .

swell

literature

- Ernst Greuter, Stefan Zima: engine damage. Damage to internal combustion engines and their causes. Vogel Buchverlag, 2000, ISBN 3-8023-1794-7 .

Individual evidence

- ↑ G. Vögtle: Requirements of today's and future large engines for the lubricant. In: Gerd P. Reinhardt among others: Lubrication of internal combustion engines. expert-verlag, 1992, ISBN 3-8169-0602-8 .