Polylactides

| Structural formula | |||||||

|---|---|---|---|---|---|---|---|

|

|||||||

| Polylactides of ( S ) -lactic acid (top) and ( R ) -lactic acid (bottom) | |||||||

| General | |||||||

| Surname | Polylactides | ||||||

| other names |

|

||||||

| CAS number |

|

||||||

| Monomer | |||||||

| Molecular formula of the repeating unit | C 3 H 4 O 2 | ||||||

| Molar mass of the repeating unit | 72.06 g mol −1 | ||||||

| Type of polymer | |||||||

| properties | |||||||

| Physical state |

firmly |

||||||

| density |

1.21-1.43 g / cm 3 |

||||||

| Melting point |

150-160 ° C |

||||||

| Glass temperature |

45-65 ° C |

||||||

| Impact strength |

0.16-1.35 J / cm |

||||||

| Water absorption |

0.5-50% |

||||||

| tensile strenght |

10-60 MPa |

||||||

| Elongation at break |

1.5-380% |

||||||

| safety instructions | |||||||

|

|||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | |||||||

Polylactides , also known colloquially as polylactic acids ( PLA for short , from the English word polylactic acid ), are synthetic polymers that count among the polyesters . They are made up of many lactic acid molecules that are chemically bound to one another . Therefore, the name polylactic acid according to the IUPAC nomenclature is misleading, as it is not a polymer with several acidic groups. Polylactides and polylactic acids are produced by different processes.

Polylactides were first described in 1845 by Théophile-Jules Pelouze . When trying to purify lactic acid by heating and removing water, he observed condensation of lactic acid molecules and the formation of oligomers and polymers. Wallace Hume Carothers , a DuPont employee , developed a process for the production of polylactides from lactides in 1932 , which was patented for DuPont in 1954.

PLA can be deformed by applying heat ( thermoplastic ). Polylactide plastics are biocompatible .

properties

Chemical properties

Polylactides are among the polyesters . These polymers, which are optically active due to the asymmetric carbon atom , occur in the form of D - or L -lactides, depending on whether they are from L - (+) - lactic acid [synonym: ( S ) - (+) - lactic acid] or from D - (-) - lactic acid [synonym: ( R ) - (-) - lactic acid].

The properties of the polylactides depend primarily on the molecular weight , the degree of crystallinity and, if appropriate, the proportion of copolymers . A higher molecular weight increases the glass transition temperature and the melting temperature , the tensile strength and the modulus of elasticity and lowers the elongation at break . Due to the methyl group , the material is water-repellent ( hydrophobic ), which lowers the water absorption and thus also the rate of hydrolysis of the main bond. Furthermore, polylactides are soluble in many organic solvents (e.g. dichloromethane , trichloromethane ; by adding a solvent such as ethanol , in which the polylactide is less soluble, it can be precipitated again). To improve the performance properties of the polylactides, they can also be fiber-reinforced during processing (e.g. injection molding , extrusion ).

Physical Properties

PLA has numerous properties that are advantageous for many areas of application:

- Low moisture absorption with high capillary effect, making it suitable for sports and functional clothing.

- A low flammability, high UV resistance and color fastness, which makes applications in furniture for indoor and outdoor areas conceivable.

- In addition, the density of PLA is relatively low, which makes it suitable for lightweight construction applications.

- The flexural strength is 0.89–1.03 MPa.

The mechanical properties of pure PLA are very similar to those of polyethylene terephthalate (PET). In particular, its transparency and low migration values make PLA ideal for use in the food packaging sector, however, compared to PET, it has a significantly higher permeability to CO 2 , oxygen and moisture and absorbs UV radiation from significantly lower wavelengths. PLA also has a lower temperature resistance. The price for PLA of around € 2 per kilogram is higher than that for PET, but it is assumed that the production costs of PLA will decrease somewhat in the coming years with increasing production quantities.

Biodegradability

Due to their molecular structure, polylactides are biodegradable , which requires certain environmental conditions that are usually only found in industrial composting plants. In addition, the degradability is strongly dependent on the chemical composition and the use of any copolymers . However, under industrial composting conditions, degradation takes place within a few months. In nature, PLA will degrade more slowly. As a microplastic , PLA leads to a protein metabolism disorder in the common mussel - a change in the hemolymph proteome . This shows that even biodegradable plastic can change the health of common mussels.

synthesis

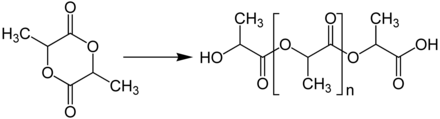

Polylactides are mainly accessible through the ionic polymerization of lactide , a ring-shaped union of two lactic acid molecules . While polylactides are produced by ring-opening polymerisation, polylactic acids are produced by direct condensation reactions .

Conversion of lactide (left) to polylactide (right) by thermal and catalytic ring-opening polymerization

Ring-opening polymerization takes place at temperatures between 140 and 180 ° C and under the influence of catalytic tin compounds (e.g. tin oxide). This is how plastics with a high molecular weight and strength are produced. Lactide itself can be carried Ver fermentation of molasses or by fermentation of glucose using a variety of bacteria produce.

In addition, high molecular weight and pure polylactides can be produced directly from lactic acid with the help of so-called polycondensation . In industrial production, however, the disposal of the solvent is problematic.

Typical processing methods for pure PLA are fiber spinning and flat film extrusion (rare).

PLA blends

PLA is actually a bio-based raw plastic (like starch , PHA , PBS and others) because it is usually not synthesized ready for use. In most cases, PLA is only tailored for the respective application through compounding . This “processing” of bio-raw plastics requires special knowledge of both additives and gentle compounding. Ready-to-use PLA compounds are also known as “PLA blends” and usually consist of PLA, other raw bioplastics (see above) and additives. Examples of manufacturers of such ready-to-use PLA blends are BASF, Danimer, FKuR, Futura Mat, Kingfa Science & Tech and Biotec.

Typical processing methods for PLA blends are extrusion (also foam extrusion), thermoforming , injection molding and blow molding .

use

packaging

The PLA growth in recent years is largely based on the use of PLA blends for packaging short-lived goods. In particular, the biodegradability is emphasized. These PLA blends have different mechanical properties than the raw PLA. In most cases, the blends can replace the conventional packaging plastics polyethylene (PE) and polypropylene (PP), such as bags or nets. Films or nets for bag applications must withstand sudden loads during the filling process and have a high weld seam strength. Films made from a PLA blend are also used for baby diapers and other hygiene products. Other examples of PLA-based packaging applications are organic carrier bags and bubble bags.

Agriculture and horticulture

Mulch films made from PLA blends compete with conventional ones made from polyethylene (PE). If conventional mulch films are costly collected, cleaned and disposed of after use, the more expensive mulch films made from PLA blends are simply plowed under after use. The individual farmer decides according to his own profitability. However, ease of use and ease of installation are important.

It is important that mulch films made from PLA blends do not biodegrade too quickly during their protective function on the field surface. However, they should biodegrade quickly after use if they have been plowed under. For this it is important that neither starch nor starch derivatives are used in the PLA blend. This is the only way to keep the mulch film insensitive to moisture. B. Weather fluctuations, and is therefore more durable.

Brackets and clips are also needed in agriculture, for. B. to give plant shoots on a pole support. These fall off as the plants grow or during harvest and have to be searched for and collected at great expense. Corresponding PLA blends with a higher proportion of PLA than z. B. in mulch films (see above) offer a practical alternative that does not have to be collected. Even film hinges can be implemented.

Catering items

There are disposable cutlery made of PLA or PLA blends on the market that cannot be used for hot food. PLA and PLA blends become very flexible and soft above approx. 50 ° C. (The bioplastic cellulose acetate is better suited here.) B. thermoformed drinking cups and made of PLA blends z. B. Manufacture drinking straws with a kink area.

Office supplies

Writing instruments and other office utensils are made from injection-moldable PLA blends. Here, the mechanical properties, depending on the PLA content, are similar to polypropylene or even ABS . The flow behavior of the melt is very important with such complex geometries.

Medical technology

One of the most important areas of application at present is likely to be medical use. Because of its degradability and biocompatibility, PLA is available for numerous applications. The human body's ability to break down PLA was first observed in 1966. PLA, often in combination with a co-polymer, is suitable as a suture material, for example. It is also possible to manufacture implants from PLA which, depending on the chemical composition, porosity and crystallinity, remain in the body for a few months to several years until they are broken down. The mechanical properties are also influenced by these factors, which means that implants can be implemented for different applications. These include, for example, nails and screws, but also plates or stents . What all implants have in common, however, is that a second intervention to remove the implant is usually not necessary, which saves the patient a second operation. PLA is also suitable as a framework material for tissue engineering . For this purpose, porous structures made of PLA fibers are made, to which different cell types, depending on the pore size, can attach.

Composite materials

In addition to applications in the packaging sector and in medical technology, PLA also has great potential as a matrix material for composite materials. By combining PLA with natural fibers , biodegradable composite materials can be produced from renewable raw materials, which represent an alternative to conventional glass fiber reinforced or filled plastics. Due to its thermoplastic character, PLA is suitable for use in (natural fiber) injection molding and extrusion areas. Components that have already been implemented are, for example, ash pods for urns, knife handles, but also the undersides of office chairs. A prototype for a cell phone upper shell has also already been developed. By adding highly elastic natural fibers, it was possible to produce a material that is able to compete with today's crude oil-based plastics.

In addition to the comparatively high costs, the low temperature resistance of PLA in particular is a problem when used in the industrial sector. Since the plastic already softens at around 50-60 ° C, it is only suitable for applications in the low temperature range, which is not acceptable for many permanent applications. According to the manufacturer, however, the temperature resistance can be improved by combining polylactides made from dextrorotatory lactic acid with those made from levorotatory lactic acid. In addition, by reinforcing with natural fibers, the temperature resistance can be increased in a range of about 100 ° C and at the same time the costs could be reduced by introducing the cheaper natural fibers in terms of the price-performance ratio.

3D printing

PLA is one of the most widely used materials by 3D printers that use the FDM process .

market

It was not until 2002 that NatureWorks LLC built the first commercial plant for the production of the plastic with a capacity of 150,000 tons. The German-Swiss company Uhde Inventa-Fischer's first pilot plant for PLA production in Germany went into operation in 2011 with an annual production of 500 tons in Guben / Brandenburg.

The companies Supla Bioplastics (member of the weforyou group), Biopearls, Guangzhou Bright China, Hisun Biomaterials, Kingfa Science & Tech., Nantong, Natureworks, Synbra and Toray also produce commercially available PLA. The weforyou group is the world's second largest manufacturer of PLA with an annual capacity of 50,000 tons of pure PLA and compounds.

recycling

The recycling code for polylactides is 07 ("others", ie "other" than 01-06).

further reading

- Caroline Baillie (Ed.): Green composites - Polymer composites and the environment. Woodhead Publishing, Cambridge 2004, ISBN 1-85573-739-6 .

- Amar K. Mohanty, Manjusri Misra, Lawrence T. Drzal (Eds.): Natural fibers, biopolymers, and biocomposites. Taylor & Francis Group, Boca Ranton, FL 2005, ISBN 0-8493-1741-X .

- Ray Smith (Ed.): Biodegradable polymers for industrial applications. Woodhead Publishing, Cambridge 2005, ISBN 1-85573-934-8 .

- Bhuvanesh Gupta, Nilesh Revagade, Joens Hilborn: Poly (lactic acid) fiber: An overview. In: Progress in Polymer Science. 32, 2007, pp. 455-482.

- L.-T. Lima, R. Aurasb, M. Rubino: Processing technologies for poly (lactic acid). In: Progress in Polymer Science. 33, 2008, pp. 820-852.

- Koichi Goda, Yong Cao: Research and Development of Fully Green Composites Reinforced with Natural Fibers. In: Journal of Solid Mechanics and Solid Engineering. 1, number 9, 2007, pp. 1073-1084.

- AP Gupta, Vimal Kumar: New emerging trends in synthetic biodegradable polymers - Polylactide: A critique. In: European Polymer Journal. 43, 2007, pp. 4053-4074.

- K. Van de Velde, P. Kiekens: Material Properties, Biopolymers: overview of several properties and consequences on their applications. In: Polymer Testing. 21, 2002, pp. 433-442.

- Introduction to Polylactic acid (Pla). In: Environmental Briefs of Common Packaging Materials. GreenBlue, Charlottesville VA 2008.

- Highlights in bioplastics. Interest group for biodegradable materials e. V., Berlin 2005.

Web links

- European trade association of industrial manufacturers, processors and users of bioplastics and biodegradable materials

- RC. Bopp NatureWorks Ingeo ™ Polylactide: Past, Present and Future

Individual evidence

- ↑ a b c d e f g h Polylactic Acid (PLA). ( Memento of February 10, 2012 in the Internet Archive ), on matbase.com.

- ↑ This substance has either not yet been classified with regard to its hazardousness or a reliable and citable source has not yet been found.

- ↑ O. Martin, L. AVEROUS: poly (lactic acid): plasticization and properties of biodegradable multiphase system. In: polymer. 42, 2001, p. 6209, doi : 10.1016 / S0032-3861 (01) 00086-6 .

- ^ A b Lee Tin Sin: Polylactic Acid. William Andrew, 2012, ISBN 978-1-437-74459-0 , p. 72.

- ^ H. Benninga: A History of Lactic Acid Making. Springer, New York 1990, pp. 203-204.

- ^ Wallace H. Carothers, GL Dorough, FJ van Natta: STUDIES OF POLYMERIZATION AND RING FORMATION. X. THE REVERSIBLE POLYMERIZATION OF SIX-MEMBERED CYCLIC ESTERS. In: Journal of the American Chemical Society. 54, 1932, pp. 761-772, doi : 10.1021 / ja01341a046 .

- ↑ Rafael Auras, Bruce Harte, Susan Selke: An Overview of Polylactides as Packaging Materials. In: Macromolecular Bioscience. 2004, 4 (9), 835-864. doi : 10.1002 / mabi.200400043 .

- ↑ Dannielle S. Green, Thomas J. Colgan, Richard C. Thompson, James C. Carolan: Exposure to microplastics reduces attachment strength and alters the haemolymph proteome of blue mussels (Mytilus edulis). In: Environmental Pollution. 246, 2019, p. 423, doi : 10.1016 / j.envpol.2018.12.017 .

- ↑ Edmund Dolfen, Patrick Zimmermann, Anneliese Kesselring, Carmen Michels: Plastics naturally! Compounding of Plastics From Renewable Resources. In: Bioplastics Magazine. Mönchengladbach 2008.

- ^ A b Hans-Josef Endres, Andrea Siebert-Raths: Technical biopolymers. Hanser-Verlag, Munich 2009, ISBN 978-3-446-41683-3 , p. 293.

- ↑ Packaging films made from renewable raw materials. In: packaging journal. 9, 2006.

- ^ RK Kulkarni, KC Pani, C. Neuman, F. Leonard: Polylactic acid for surgical implants. In: Archives of Surgery . 93, No. 5, 1966, pp. 839-843.

- ↑ Kunststoff-Fabrik Nature trends and developments in biopolymer research. Fraunhofer IAP press release, January 24, 2011.