Sawmill

Sawmills (regional also saw , sawmill , sawmill (CH), Sagi (CH), cutting mill , board mill , board mill or Brettsäge are mentioned), farms, the work-up of the forestry delivered round wood to boards , squared timber and beams serve.

Products and process units

The products are also called sawn timber . The cut is made mainly on gang saws , but also on band and circular saws . Nowadays, profile hoggers are also increasingly used.

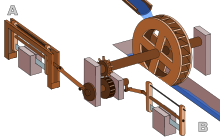

In the past, they were mostly driven by a water wheel , later by steam engines (see: Steam sawmill ) or diesel engines and now usually with electric motors .

A sawmill essentially consists of the following process units:

- Log yard - delivery and storage of logs

- Log sorting system - debarking, electronic measurement and sorting of logs

- Cutting line - the heart of the sawmill. Here the round timber is processed into sawn timber. Frame saws and band saws were and are traditionally used as the main machines . Modern systems use powerful hogger / circular saw combinations, profile chippers or gate / circular saw combinations.

- Sawn timber sorting - squared timber, planks, boards and more are electronically measured here and sorted according to size and quality.

- Packing or stacking system - the sawn timber is collected here for storage or drying in so-called air stacks or ready-made shipping packages .

- Drying system - In drying chambers, the sawn timber is brought to the wood moisture required for further processing and use .

- The main product is sawn timber, which is processed into glued laminated timber , solid structural timber (KVH), solid wood panels, planed goods, profiled timber or rough sawn for various building purposes (roof structures, roof cladding, external cladding, various building purposes).

The saw-by- products are also recycled:

- Bark is burned for heating purposes ( biomass ) or turned into bark mulch.

- Sawdust, sawdust and sieves are used as raw materials in the fiberboard industry or pressed into pellets .

- Wood chips and chopped wood are mainly used in the paper industry for pulp manufacture or are also burned for heating purposes or pressed into pellets.

A basic distinction is made between hardwood and softwood sawmills.

Pollmeier Massivholz GmbH & Co. KG operates the largest hardwood sawmills in Germany . The company is headquartered in Creuzburg and operates two other sawmills in Malchow and Aschaffenburg . Well over 600,000 solid cubic meters of beech logs are cut every year at the three locations.

Ilim Nordic Timber in Wismar has the largest softwood sawmill in Europe. On two profiling lines from LINCK HVT , 2.2 million solid cubic meters of round wood are processed annually in multiple shifts . The feed speed of line I is a maximum of 150 meters per minute, that of line II a maximum of 160 meters per minute.

In terms of production capacity, the Finnish-Swedish group Stora Enso Timber is the second largest forest company in the world. The company operates 25 sawmills in eleven countries, processing 7.5 million cubic meters of sawn timber products. At over 700 years, Stora Enso is the world's oldest public company.

history

The forerunner of the sawmill is the pit saw , here the trunk was cut up by two people using a vertical saw. Corresponding constructions were later set up for this purpose (see also Underdog (Sociology) ).

The Hierapolis sawmill was a Roman water-powered stone sawmill in Asia Minor (present-day Turkey ) from the 3rd century AD. The water mill is the first known machine in which a rotary motion was converted into a linear motion using a crankshaft and connecting rod .

A written testimony to the ancient operation of water-powered marble saws near Trier can be found in Ausonius ' poem Mosella from the late 4th century AD. A text passage written around the same time in the work of Saint Gregory of Nyssa indicates the existence of marble sawmills also in the Anatolian region , so that a widespread use of such industrial mills in the late Roman Empire can be assumed. Another sawmill could have stood in Augusta Raurica , Switzerland , where a metal crankshaft from the 2nd century AD was discovered.

Other Roman or Byzantine stone sawmills that worked with a crank and connecting rod but without a gear drive were excavated in Gerasa ( Jordan ) and Ephesus (Turkey). Both mills date from the 6th century AD. It is not known whether there were stone and wood saw mills in Roman and early Byzantine times.

In Europe, the technology for running a sawmill was lost and forgotten for centuries in post-Roman times. It was not until the High Middle Ages that sawmills were documented again in Europe. In 1204 a plank mill is mentioned in Evreux (Normandy) , which is probably the oldest documented mention of a sawmill, but nothing is known about its functioning. A drawing by the French architect Villard de Honnecourt was made between 1220 and 1240 and shows the mechanism of a sawmill. A hydropower saw is documented in the Swiss Jura for the year 1267. The oldest known sawmill in German-speaking countries is a wood mill, first mentioned in 1279, between Riehen and Basel . The oldest post-antique sawmill in Germany is the Urtelmühle in Lenggries, mentioned in 1295. Other early sawmills in Germany are especially attested for the southwest: 1298 in Freiburg im Breisgau , 1310 in Kirchheim unter Teck , 1311 in Pfaffenweiler in Südbaden, 1313 in Selbach and 1314 in Peterzell . In 1322, the Hanrey sawmill near Augsburg is documented in a building authority account . Sometimes it is wrongly called the oldest sawmill in Germany. In 1340 a sawmill is mentioned in Zurich and in 1361 one in Graubünden.

literature

- Edgar Finsterbusch, Werner Thiele: From stone ax to saw gate. A journey through the history of woodworking. Fachbuchverlag, Leipzig 1987, ISBN 3-343-00275-5 .

- Ivo Franz : Historical sawing industry in Brandenburg: Development from 1850 to 1990, 2009 ISBN 978-3-8366-7849-0

- Jürgen Gaebeler: Folklore-historical hodgepodge sawmills - saws. Deutscher Betriebswirte Verlag, Gernsbach 2002.

- Jürgen Gaebeler: The early history of the sawmills as a result of mill diversification. 1st edition 2001. 2nd edition Verlag Kessel, Remagen-Oberwinter 2006, ISBN 3-935638-20-5 . ( Digital copy [extract] )

- Tullia Ritti, Klaus Grewe, Paul Kessener: A Relief of a Water-powered Stone Saw Mill on a Sarcophagus at Hierapolis and its Implications. In: Journal of Roman Archeology. Volume 20 (2007), pp. 138-163.

- Andrew Wilson: Machines, Power and the Ancient Economy. In: The Journal of Roman Studies . Volume 92 (2002), pp. 1-32.

- Grewe, Klaus: The relief representation of an ancient stone saw machine from Hierapolis in Phrygia and its significance for the history of technology. International conference 13. – 16. June 2007 in Istanbul ( Memento from May 11, 2011 in the Internet Archive ) (PDF; 2 MB) In: Bachmann, Martin (Hrsg.): Construction technology in ancient and pre-ancient Asia Minor. Byzas, Volume 9. Ege Yayınları, Istanbul 2009, ISBN 978-975-807-223-1 , pp. 429-454.

Individual evidence

- ↑ a b Ritti, Grewe, Kessener (2007), p. 161.

- ^ Wilson (2002), p. 16.

- ↑ Schiöler (2009), p. 66f.

- ↑ Ritti, Grewe, Kessener (2007), pp. 149–153.

- ↑ Detailed description of the mechanics and technology of historical sawmills by Peter Nikolaus Caspar Egen : Sägemühlen . In: ders .: Studies on the effect of some existing waterworks in Rhineland-Westphalia , ed. from the Ministry of the Interior for Trade, Industry and Construction, Part I-II. A. Petsch, Berlin 1831, pp. 168-171 ( Google Books ).

- ↑ www.falkenmuehle.eu .

- ↑ www.historische-saegen.ch .

- ↑ Stefan Hess : Between Hobelbank and Plow , in: Jahrbuch z'Rieche 2012 ( online ).

- ↑ Art. Wassermühlen, in: Mittelalter-Lexikon ( Memento of the original from March 16, 2016 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. .

- ^ Hans Jänichen : On the history of the sawmills in the Middle Ages, in: Alemannisches Jahrbuch 1961, pp. 317–329; Jürgen Gaebeler: The early history of the sawmills as a result of mill diversification. 2nd edition. Verlag Kessel, Remagen-Oberwinter 2006, p. 3 ( Memento of the original dated February 9, 2015 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. .

- ↑ Art. Wassermühlen, in: Mittelalter-Lexikon ( Memento of the original from March 16, 2016 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. .

- ↑ www.historische-saegen.ch .