Braked weight

The braked weight is a physically incorrect, but historically grown quantity, specified in the unit ton , for evaluating the braking capacity of a railway vehicle or a train .

The term braking mass , which is also used instead of braked weight, does not correspond to the standardization.

Dependency of the braking force

From the type of braking

In addition to the vehicle mass (weight) that can be used to transmit braking force between wheel and rail , the braking weight also includes the type of braking , which can be changed manually on each vehicle. The following braking positions are possible:

- With the fast-acting P-brake , light to medium-weight trains are braked. It enables a braking ratio of around 100%.

- The R-brake can apply significantly more than 100% braking ratio. With cast soles, their effect is increased in the upper speed range; with disc brakes, the brake pressure is generally increased. (Both require additional regulation and monitoring, in the form of a speed sensor and / or anti-skid device.)

- The slow-acting G-brake is used for heavy freight trains that are not made of uniform wagon material or for extremely long freight trains . The braking ratio of the G-brake is a maximum of around 80%.

- The magnetic rail brake (Mg brake) is used in addition to the R brake for rapid braking , whereby braking ratios of up to 200% are possible.

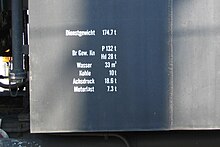

For vehicles with a changeover device for the type of braking, the corresponding braked weight is written on the vehicle for each braking position.

From the loading

The load deceleration enables the braked weight to be adapted to the effective weight of the vehicle. To prevent overbraking when the vehicle is lightly loaded, the braked weight of an empty wagon is lower than when it is loaded. Depending on the type of vehicle, the load change is changed manually or automatically. In the case of wagons with manual load change, the corresponding braked weight is written on the wagon for each position.

If a vehicle is loaded without load braking , not only does its total weight increase, but also the braking distance , because the braking effect is reduced as the load increases.

From other factors

The size of the braking force also depends on:

- the brake pad force

- the design of the brake pads and their coefficient of friction

- the time course of the brake pad force

- the driving resistance

- the mass factor

The braked weight only characterizes the property of a brake and not that of the vehicle. Vehicles of different types and masses that are equipped with brakes of the same type therefore have the same braked weight.

Brake calculation

In practice, it is necessary to know the braking behavior of a train made up of different individual wagons in order to decide up to what speed the train can safely maintain its specified braking distance depending on the respective route incline. When determining the braking power of a train, the braking forces of all vehicles are combined. The brake calculation is used to determine the braked weight of a train by adding up the braked weights of the individual vehicles. In order to express the braking performance of the different trains with their different loads in a comparable value, the braked weight of the train is compared with the total mass of the train (train weight). The result is called the braking percentage or braking ratio . This value can then be used to determine how fast a train can travel without the braking distance exceeding the distance from the distant signal .

Germany

The distances between the pre- signal and the main signal are standardized in Germany and are referred to as the standard braking distance . As a rule, they are 400 or 700 meters on branch lines, depending on the maximum line speed, and 1000 meters on main lines. The minimum braking percentages in Germany determine how many braking percentages a train must have in order to be able to travel a certain route at the maximum route speed.

Austria and Switzerland

Basically, trains in Austria are to be formed in such a way that the wagon train for itself and the working locomotives are individually able to apply the required braked weight. Otherwise, a new brake calculation is carried out, which takes into account the service and brake weights of all working locomotives in the train. If the required braked weight is still not achieved, the dispatcher uses the disposition list to check how far a reduction in the maximum speed is necessary.

In contrast to Germany, Austria and Switzerland do not have standardized distant signal distances. In Austria, they are between 400 and 1500 meters, each rounded to 100 meters.

At the Swiss Railways , the brake series and the train series are determined with the brake calculation . The train speed, which is determined by the route table, depends on the train and brake series .

Holding or holding brake weight

In Switzerland, the braking weight refers to the braking weight required to hold the train stationary. Before starting the journey, the required braked weight of the parking brake must be checked. The necessary holding brake weight depends on the weight of the train and the slope of the route and is stipulated in the driving service regulations.

In Austria, the handbrake weight necessary to secure stationary vehicles is called the holding brake weight. However, the holding brake weight is only to be checked on freight and service trains . The braking hundredths of a stop can be found in the route list. If the holding brake weight cannot be applied using the hand brakes, the brake shoes on the locomotives may be used.

Determination of the braked weight

The braked weight is determined in braking and coasting tests standardized by the UIC or calculated using test documents.

In 1936, the longest and heaviest passenger train with 15 cars in operation at the time was used to determine the characteristic course of braking. Building on this, the standards for determining the braked weight were created. For the fast-acting passenger train brake, the standard brake car is a four-axle 50-ton bogie car with a brake cylinder filling time of 4.7 seconds, with the sum of all brake pad forces being 80% of the vehicle mass, i.e. H. is around 400 kN. In the case of rapid braking after pushing off at a vehicle speed of 120 km / h for the standard brake car including the locomotive not braked, this enables a braking distance of 1000 meters, which corresponds to an average deceleration of about 0.56 m / s². For the slow-acting freight train brake, a two-axle freight wagon is internationally defined as a standard wagon, which is braked with 70% of the vehicle mass.

The tests to determine the brake weights are carried out on horizontal stretches. Calculating the braking distance is very difficult because it depends on a number of factors that are difficult to determine. The Minden formula provides a relatively precise determination of the braking distance for vehicles with block brakes .

BAV braked weight

The narrow-gauge railways in Switzerland not the UIC brake weight is used, but a from the Federal Office of Transport defined (FOT) Brake weight. 100 braked weight hundredths λ correspond to an average deceleration of 1 m / s 2 when braking from 50 km / h on a horizontal route. The braking test drives can take place under these conditions on the respective rail network . If no suitable route section is available for topographical reasons, the measured distance can be converted to a braking distance that corresponds to 0 ‰.

The braked weight is determined from the braked weight hundredth λ:

Earlier explanation of the braked weight

In the past, the braked weight of a vehicle was defined as that portion of the vehicle's weight that was used to transfer braking force between the wheel and the rail.

This physically correct explanation differs from the practice of railway operations. The theoretical requirement that the entire train weight is immediately available in full for the transmission of braking force at the beginning of the braking process is not given, since the braking force does not build up suddenly. With this in mind, a smaller coefficient μ was chosen as the effective coefficient of friction between rail and wheel.

Brake weights of some vehicles

| Locomotive, multiple unit | v max | Service weight | R + EP | R. | P | G | towed |

|---|---|---|---|---|---|---|---|

| SBB Re 4/4 II | 140 km / h | 84 t | - | 100 t | - | 72 t | 0.9 t |

| SBB Re 450 (Zurich S-Bahn, 1st generation) | 130 km / h | 74 t | - | 85 t | - | 63 t | 0.85 t |

| SBB Re 460 ("Lok 2000") | 200 km / h | 84 t | - | 105 t | - | 76 t | - |

| SBB Ae 6/6 | 120 km / h | 120 t | - | 120 t | 90 t | 90 t | 0.75 t |

| SBB Re 6/6 | 140 km / h | 120 t | - | 150 t | - | 108 t | 0.9 t |

| SBB RABDe 500 (ICN InterCity tilting train) | 200 km / h | 359 t | 751 t | 631 t | 408 t | 408 t | 1.14 t |

| RABe 514 (DTZ of the S-Bahn-Zurich) | 140 km / h | 225 t | - | 368 t | - | - | 1 t |

| SBB RBe 4/4 | 125 km / h | 72 t | - | 85 t | - | 55 t | 0.76 t |

| SBB RBDe 560 (NPZ, Domino) | 140 km / h | 70 t | - | 88 t | - | 70 t | 1 t |

| BLS Re 465 | 160 km / h | 84 t | - | 114 t | - | 76 t | - |

| SOB RBDe 562 (SOB-Flirt) | 140 km / h | 74 t | - | 93 t | - | 74 t | 1 t |

| DB class 101 | 220 km / h | 84 t | 168 t | 120 t | 84 t | 70 t | - |

| ÖBB 1116 | 230 km / h | 86/88 t | 180 t | 140 t | 67 t | 67 t | - |

The pictures on this page provide further examples.

| Passenger cars | v max | Empty weight | total weight | Mg | R + EP | R + SB | R. | P |

|---|---|---|---|---|---|---|---|---|

| ÖBB Railjet intermediate car Bmpz, ARbmpz, Ampz | 230 km / h | 50 t | 54-56 tons | 119 t | 87 t | - | 81 t | 59 t |

| ÖBB Railjet control car Afmpz | 230 km / h | 56 t | 60 t | 112 t | 94 t | - | 88 t | 64 t |

| SBB EW IB (gray-blue) | 140 km / h | 30-32 t | 33-33 t | - | - | 43 t | 43 t | |

| SBB EW II A (green) | 140 km / h | 29 t | 32 t | - | - | 43 t | 43 t | |

| SBB EW II B (green) | 140 km / h | 30 t | 33 t | - | - | 43 t | 30 t | |

| SBB EW IV A, B, WRM | 200 km / h | 42-46 t | 47-50 t | - | 74 t | 69 t | 51 t | |

| SBB IC Bt ( EW IV ) | 200 km / h | 48 t | 53–54 t | 81 t | 77 t | 72 t | 57 t | |

| SBB D ex SNCF | 160 km / h | 29 t | 34 t | - | 49 t | 46 t | 46 t | |

| SBB IC2000 (Dosto) A, AD, B, Bt, BR, WRB | 200 km / h | 45-47 t | 60 t | 91 t | 86 t | 81 t | 65 t | |

| SBB BPM 51 | 160 km / h | 36 t | 42 t | - | - | 56 t | 56 t | |

| SBB Eurocity car Apm, Bpm | 200 km / h | 43 t | 47 t | - | - | 68 t | 50 t | |

| SBB Eurocity car Apm and Bpm refit | 200 km / h | 45 t | 50 t | 76 t | 73 t | 68 t | 50 t |

For a Railjet set consisting of 1 × 1116 + 6 × wagon + 1 × control car this results in:

- for the tensile mass and

- for the braked weight and thus

- for the brake hundredths .

According to the book timetable, 191 brake hundredths are required for the Vienna – Bregenz route. If you put two Railjet sets together, the braked weight and train mass are doubled in each case, the braked hundredths remain the same.

See also

Individual references, comments

- ↑ Institute for Transport Planning and Transport Systems : Glossary of Public Transport ( Memento of the original from February 23, 2012 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , ETH Zurich

- ↑ a b c d Austrian Federal Railways : V3. Operating regulation . Vienna, 2005. § 26

- ↑ a b c Frank Minde: Fundamentals of Railway Brake Technology (PDF; 144 kB). Minden (Westphalia), 2007

- ↑ a b Jörn Pachl: Glossary of the system technology of rail traffic . Retrieved June 26, 2013

- ↑ Federal Office of Transport: Swiss Driving Regulations (FDV) A2016 Federal Office of Transport (FOT), July 1, 2016 (PDF; 3 MB). R 300.14, Section 6.5–6.7 Passenger and freight train brakes

- ^ A b c d Jürgen Janicki, Horst Reinhard: Rail Vehicle Technology. Bahn Fachverlag, 2008, ISBN 978-3-9808002-5-9 .

- ↑ Swiss Driving Regulations (FDV) A2016 Federal Office of Transport (FOT), July 1, 2016 (PDF; 3 MB). R 300.14, Section 3.4 load braking

- ↑ a b c d Lexicon railway . Transpress VEB Verlag for Transport , Berlin, 1978

- ↑ in Switzerland referred to as the braking bill ( Swiss Driving Service Regulations (FDV) A2016 Federal Office of Transport (BAV), July 1, 2016 (PDF; 3 MB). R 300.1, Section 3.2 Explanation of terms )

- ^ Jörn Pachl: System technology of rail traffic. Plan, control and secure rail operations . Vieweg + Teubner, Wiesbaden 2008, ISBN 978-3-8351-0191-3

- ↑ Abbreviation for disposition list (Austrian Federal Railways: V3. Operating regulations . Vienna, 2005. page C)

- ↑ a b Swiss Driving Regulations (FDV) A2016 Federal Office of Transport (FOT), July 1, 2016 (PDF; 3 MB). R 300.1, Section 3.2 Explanation of the terms

- ↑ Handbrake or spring-loaded brake weight

- ↑ Swiss Driving Regulations (FDV) A2016 Federal Office of Transport (FOT), July 1, 2016 (PDF; 3 MB). R 300.5, Section 3.7.2 Maximum speeds and maximum permissible length of the trains and enclosure 1 table of minimum holding force

- ↑ F. Christen: Determination of the braked weight of the railway vehicles equipped with compressed air brakes . Schweizerische Bauzeitung, Volume 122 (1943), Issue 4 (E-Periodica, PDF 1.9 MB)

- ↑ with its own track body

- ↑ Implementing provisions for the Railway Ordinance (AB-EBV) DETEC , July 1, 2016 (PDF; 3 MB). AB 52.2 braking force

- ^ A b W. Wyssling: Communications from the Swiss Study Commission for Electrical Railway Operations . Schweizerische Bauzeitung, Volume 52 (1908), Issue 17 (E-Periodica, PDF 4.4 MB)

- ^ Jörn Pachl: Textbook system technology of rail traffic . Additional information on the individual chapters , accessed on June 26, 2013

- ↑ ÖBB 1116 024-9 technical data. In: Bahnbilder.de. Retrieved October 13, 2017 .

- ↑ a b Lilian Meier: Fahrdienst. Summary for train staff from driving regulations, operating regulations, implementation regulations, R174.1 and work instructions . Alterswilen, 2011

- ↑ a b Federal Accident Investigation Office: Train separation Z 568 (Railjet) on October 6, 2010 . Vienna, 2011 ( PDF )