table tennis racket

The table tennis racket is the play equipment for playing table tennis . Its main components are the handle, the covering and the wood of the blade. The right choice of racket is very important for a player because it can effectively support their own style of play.

In official competitions, only a racket that complies with the rules and whose rubbers are approved by the World Table Tennis Federation ITTF may be used. There is a list of “approved coverings” for this purpose, which is constantly updated.

Handle of the racket

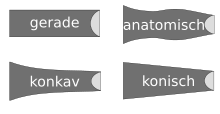

The handle of the racket can have different shapes. These are essentially:

-

straight

With the straight grip of the racket, the player can vary most easily during the game. Defensive players like to use slim, straight handles because the stick can then be turned better in the hand (to swap forehand and backhand side). - concave

- anatomically

-

conical

Concave, anatomical or conical handles can be fixed more easily at the end of the handle and thus held without fatigue. Offensive players therefore like to use this grip shape.

Unpainted handles have become popular on competition rackets because they absorb hand sweat better and less slip in the hand. However, the following applies: The player can only find the right grip by trying it out. Every hand and every playing technique is individual. Many players use a file and sandpaper to add the finishing touches to their clubs.

Coating of the racket

The racket surface has the greatest influence on the speed and rotation (also called spin or spin) with which the table tennis ball can be played.

One side of the table tennis racket that is used for striking must have a covering. A side that is not used for striking can be provided with any material (e.g. cork) or remain unoccupied - but today it also has to be colored bright red or black. From 1961 to 1971 both sides of the racket - if they were covered with a coating - had to be of the same color (dark red, dark blue, dark green, dark brown, black, not light-reflecting). After that, this regulation was relaxed and the clubs were allowed to have any color - but not white - on both sides. As the industry continued to develop new rubbers with different properties (fast, slow, very grippy or very smooth ...) the possible - although no longer mandatory - color of the rubbers became a problem. Many players took advantage of the scope of the rules by sticking rubbers of the same color on both sides, some of which had completely different properties. When serving (later also when returning during the game) they turned the club so that it was difficult for the opponent to judge which rubber was hit. This led to seemingly minor mistakes by misjudging the rotation of the ball, which made the game unattractive in the opinion of ITTF officials. The Chinese Huang Liang was among the first to successfully use this club spin.

“[Huang Liang] made everybody look ridiculous. I mean really ridiculous — he annihilated Surbek and Johansson under 10 and had Bengtsson 15-1 one game "

Some rubbers (antitopspin and pimples without a sponge) produced a different sound when the ball hit the racket, so that the recoiler could tell from the sound with which rubber the hit had been made. In order to prevent the perception of the deviating noise, some hitters (for example Engelbert Hüging ) stamped their feet on the ground at this moment. The ITTF Congress ended this development during the World Table Tennis Championships in 1983 with the rule that from January 1, 1984, every player had to use different colored rubbers at all international events, although the colors themselves were initially not required. At the same time, foot stomping was banned (allowed again since September 1, 1991). In order to avoid poorly distinguishable color combinations such as “dark wine red / black” or “orange / red”, the rule was changed in 1984 so that the colors of the coverings were no longer allowed to have common components (because of orange / red or dark brown / black). In order to put an end to all interpretation disputes (for example, "orange / green" was now a prohibited color combination because of the common color component "yellow"), the rule was then revised in 1985, so that from July 1, 1986 on international Events only bright red and black were allowed as surface colors. This color combination has been mandatory in the national area of the DTTB since July 1, 1988. During the 2019 World Cup in Budapest, the AGM (Annual General Meeting) decided that other colors would also be allowed after the 2020 Olympic Games: the surface on one side of the racket must be black, the other side may have a light-colored surface. This light color must be clearly different from black and from the color of the ball.

In the 1950s, many players only covered the racket with a foam rubber, sometimes 2 cm thick. In addition to the enormous speed and spin possibilities that these rubbers offered, the fact that you could no longer hear the shot was a problem. This actually leads to coordination problems in the fast game at the table. As a result, these surfaces were banned by the ITTF on April 4, 1959 in Dortmund . The maximum covering thickness was set at 4 mm. The players then stuck a knobbed rubber on the foam layer - optionally with knobs facing in or out. The maximum thickness of the pimple rubber is 2 mm - normally the layer on coverings with pimples on the inside is only 1.6–1.7 mm thick, leaving 2.3–2.4 mm for the sponge underlay. In technical jargon, the “mm” is usually left out of the flooring thickness, so that a “1.5” flooring means that the flooring has a 1.5 mm sponge underlay.

The club coverings can be divided into two groups: pimples outside or pimples inside. With both variants, the surface must have between 10 and 30 pimples per square centimeter.

Knobs outside

In the case of pimple-outside coverings, a fundamental distinction must be made between

- "Short" studs (stud length less than approx. 0.9 mm)

- "Long" knobs (knobs length from approx. 1.3 mm to approx. 1.8 mm. If the knobs have a length of approx. 0.9 mm to 1.3 mm, one also speaks of medium-long or half-length knobs.)

Short knobs on the outside

In the case of coverings with short pimples, there are additional features in the construction that cannot be derived directly from the name.

- The covering is made of firm, hard rubber material.

- The backing layer (not the sponge) under the knobs is laid out thick.

- The knobs have a large cone at the base , so they are not cylindrical there.

- A firm sponge is used as a sponge pad.

The combination of these manufacturing features ensures that the surface in comparison to the backside surface

- less spin generated (because of the lower grip of the surface)

- is less sensitive to opposing spin (see above), d. H. less spin reversal and trajectory influencing by the spin of the ball

- Generates high speed with hard shots without being massively influenced by the spin of the ball (due to tension in the carrier layer and great pressure on the sponge pad)

- the ball contact time is significantly reduced.

This rubber variant is the suitable material for players who are looking for the first chance for the decisive shot through fast counter-play while largely dispensing with topspins. The players of the classic Chinese TT school [u. a. Chuang Tse-Tung (TT world champions 1961 , 1963 and 1965 ) and Li-Fu-Yung - early to mid-1960s] used this material, but z. B. also the Czech Milan Orlowski (who became European champion in 1974 with such a rubber on the backhand side). In the offensive game, because of the lack of spin at the same speed, the ball has a longer trajectory than a topspin (due to the Magnus effect ), which means that in many cases the ball - precisely because of the lower trajectory curvature - cannot hit the (purely physically possible) maximum speed, because otherwise it would not hit the opposing half of the table. Although players are able to generate spin with these rubbers, the result cannot be compared with the rotation that can be generated with a pimple-in rubber.

Long knobs on the outside

Coverings with long pimples are manufactured according to different specifications than the short pimples:

- the surface is made of soft, flexible rubber material

- the backing layer (not the sponge) under the knobs is laid out thinly

- the knobs have almost no cone at the base and are almost cylindrical.

- a thin, soft sponge is used as a sponge pad.

- Most of the long knobs are also available in a sponge-free version (orthodox or ox for short)

The combination of these manufacturing features ensures that the knobs have the following properties:

- variable grip (due to the movable ball contact surface due to the low stability of the pimples or corrugation of the pimple surface)

- relatively insensitive to opposing spin (see above)

- Due to a guideline of the ITTF from May 1998, which stipulates the upper limit of 1.1 of the ratio of pimple length / pimple width from the 1999/2000 season (previously the maximum ratio was 1.3), pimples no longer buckle and have so easily when the ball is in contact as a result, the so-called disruptive effect is lost. However, today (October 2008) there are again initial attempts by various manufacturers to use innovative rubber materials to achieve an effect equivalent to buckling the knobs. It remains to be seen whether this will succeed - in view of the now rather narrow regulations for minimum grip.

Above all, the variable grip, which makes the cut difficult to calculate, makes the ball difficult to assess for some players from lower classes. Higher-class attacking players, on the other hand, take advantage of the low offensive and tempo possibilities of the long pimples for their game. The specific characteristics of the spin and elasticity properties depend not only on the shape, but also to a large extent on the rubber compound and the type of production - especially the surface treatment (see below) - and can vary from product to product.

There are basically two types of long knobs:

- smooth long knobs. With this type of pimple, the surface has been treated and the grip has been greatly reduced. The knobbed heads are very smooth and can be pulled through almost smoothly under the ball when playing the ball. In the case of the push and block ball with the smooth long knobs, the change in direction results in a theoretical cut reversal (cut forwarding), although the twist is not changed, e.g. B. the opponent's overcut becomes undercut through the pimples and vice versa, while the long pimple necks create the undercut familiar from long pimples in the long defense against cuts. For pure block players there are also versions with smooth pimple necks that completely return the topspin as an undercut when blocking. From July 1, 2008, knobs that are less than a minimum grip are no longer permitted.

- grippy long knobs. This type of pimple is mostly used by defenders. In defense away from the table, the backspin can be varied relatively independently of the opponent's topspin (in contrast to smooth long pimples). When blocking on the plate, the ball is usually played back with a slight forward spin - unlike the smooth long knobs. Therefore, there were also long pimple rubbers (from Yasaka) for offensive counter play.

In Germany made Engelbert Hüging these types of deposits popular as he was in 1978 with a combined bats (pimples inside / long pips) German in Lübeck master. Long pimples were first used in the Bundesliga from 1975 by Dr. Georg Nicklas (Saarbrücken). Today there are only very few players in the Top 100 (e.g. Chen Weixing and Joo Se-hyuk ) who play with long pimples, as the two-color rule allows the expected rotation of the ball to be calculated before the stroke and the Attacking players can respond with hard slamming balls without any problems. The success of the above-mentioned players is based on an attacking game with tactically used undercut balls to confuse the opponent.

The idea of coverings with smooth long pimples came about in the late 1980s and early 1990s. Similar to speed gluing, which is limited to the sponge, the playing characteristics corresponding to the type of covering have been massively changed by changing the rubber surface (treatment with hairspray, spray paint, solvents, UV light, microwave, heat (oven, iron)) ( similar to anti-covering, but with a more variable cut). This rubber could also be bought more or less industrially manufactured, namely from Toni Hold, who reworked TSP rubbers, which developed into real bestsellers. This is exactly where the (understandable) argumentation of the ITTF began to ban these coverings. Namely, that two rubbers with the same name had completely different properties. The industry responded by changing its name to make aftercare legal. As a result, in 2008 a required, albeit practically hardly verifiable, minimum grip for long pimple rubbers was prescribed, which meant the at least official end of the smooth long pimples.

Pimple rubber (classic)

Pimple rubber was the first rubber ever. Allegedly, the Briton John Goode is said to have bought the pimple pad on the counter on the way to a table tennis tournament in the supermarket in 1902, stuck it on the racket and won the tournament. Until the development of sandwich rubbers, this was the only material that table tennis was played with. The native Hungarian, later Englishman and record world champion Victor Barna also played with such a rubber. A club was later sold under his name, so that Barna became a synonym for pimple rubber or pimple rubber bat, as it was without competition for a long time. [The Barna stick wood (a triple veneer made of beech + ash , which was particularly suitable for playing with pimple rubber due to its somewhat top-heavy weight distribution) is still a legend among older players]. The design of the pimple rubber corresponds to pimples on the outside without a sponge pad (only textile fibers for stabilization).

The pimple rubber dominated the table tennis scene in Japan until the invention of the backside rubbers in 1952. Because the twist was limited and easy to calculate due to the lack of variation options, pimple rubbers were only used internationally as combination flooring. The last successful player with this type of rubber was Eberhard Schöler , who was vice world champion in 1969, who used a pimple rubber on the backhand side and a pimple-inside rubber on the forehand side. Nevertheless, there are still successful so-called “board players” in the lower and middle classes, whose success is based on the rarity of their material. The international approval for official tournaments for the Barna rubber - the best-selling pimple rubber - ended - after a transition period - on June 30, 1998, because the manufacturer Dunlop-Sport withdrew from the table tennis business and did not apply for a new ITTF rubber approval.

Even today, so-called “board tournaments” (hardbat) take place, especially in the USA and Germany, in which only clubs with rubber studs are allowed.

Literature on knobs outside

- Rahul Nelson: Always these knobs , DTS magazine , 1986/7 page 21

- Siegfried Möller: Lange Noppen , DTS magazine , 1993/3 pages 22-25 and statements from table tennis experts: 1993/3 pages 26-28

Nubs inside (backside)

If the knobs of the rubber point inwards with a smooth surface on the outside, this is the most commonly used table tennis rubbers. By choosing a suitable mixture of natural rubber and synthetic rubber, you can produce extremely fast, less grippy (natural rubber) or slow, extremely grippy coverings (synthetic rubber). With this rubber you can give the ball by far the most rotation (topspin, sidespin, undercut). The thicker the underlying sponge (max. 2.5 mm), the faster the maximum possible ball speed; the more adhesive the surface, the higher the maximum speed of the ball, whereby thick substrates always generate more rotation than thin ones when the ball is immersed, even with the same surface.

Backside rackets are the most versatile. With a thick sponge underlay (over 1.7 mm) they are suitable for attacking spins and blocking, with thin (1.0 - 1.5 mm) sponges they are also suitable for defense against undercuts. Modern table tennis offensive game in its current speed and topspin form was only possible with the invention of the sandwich surface with a backside surface.

Offensive rubbers have a significantly thicker and faster sponge and a highly elastic rubber surface (for maximum spin and speed), in contrast to defensive rubbers, which usually have thin, speed-absorbing sponges combined with a soft, usually sticky surface (for maximum undercut).

Anti-topspin rubbers

These rubbers have an inelastic, non-slip top sheet with very short, wide knobs (inside) and a soft, strongly speed-absorbing sponge. Purely in terms of construction, they belong to the pimple-inside rubbers - but differ so much in terms of playing technology that a separate category is justified. They are highly spin and tempo-absorbing and are ideally suited to fending off topspins and other attack strokes - be it through blocks or apparent backspin defensive strokes (which, however, do not produce much cut with this material).

The idea for the anti-topspin rubber came from the Austrian inventor and national player Toni Hold, who was the first to achieve success with this type of rubber with his own construction. However, these were withdrawn from him because his surface was not produced industrially. This was then made up for by Joola with the help of Toni Hold in 1969. It was followed by copies from other manufacturers, which never achieved the effect of the original, but did not differ in terms of gloss, sound or design of the cut surfaces. The Englishman John Hilton became European champion with this type of rubber in 1980 in Bern.

After initially widespread use among defensive specialists, this type of rubber is now being replaced more and more by the long pimples (some with smooth pimple heads), because they offer more opportunities, especially due to the variable cut of the ball, to pose problems for the attacker and to make mistakes entice. Toni Hold was also a leader in drafting and designing the smooth long pimples, as well as being a leader in senior championships.

Since the ban on smooth long pimples (2008), several companies have developed a new type of anti-rubble, which is also referred to as Glanti (smooth anti) in technical jargon in various forums. These have extremely little to no grip, longer pimples on the inside and shine above all because of their sometimes excellent pattern transmission ("reversal") with passive play (hold-off block). Most of these new antis are also faster and therefore more difficult to control than classic antis or smooth long knobs.

Combination racket (backside / anti or long pimples)

Combination rackets combine the different types of surface, namely non-slip pimple inside and long pimple or pimple outer coverings. In the defensive version (long knobs) it is achieved by turning the club quickly that the opponent has to spend part of his attention on assessing the rotation of the ball and initiating appropriate strokes. Due to the two-color rule, this variant has become so harmless that it is simply "shot" in higher classes, while the offensive variant (pimples outside) is mainly used by Asian players.

Speed glue

With speed gluing (or simply "gluing" in the game of players) the rubber covering of the stick is only glued to the stick shortly before the start of the game. Special adhesives are used that make the surface more grippy, more elastic and therefore more easy to spin. The covering is glued to the wood almost "wet". The solvents in the adhesive ( benzine , trichlorethylene , ethyl acetate , benzene and other aromatic hydrocarbons ) then diffuse through the sponge and penetrate the knobbed cover layer. The rubber covering swells up and becomes more elastic. Due to the greater mobility of the top layer (rubber lining) on the swollen foam rubber pad, tangential ball contact (topspin) results in material tension, which gives the ball greater speed and, above all, more rotation after a longer ball contact phase. As a result, direct points are already possible with the opening topspin. Therefore, this method is used by almost all aggressive attacking players, even in the lower classes and by young people. In addition to ball safety, this primarily affects the durability of the surface. In order to extend the durability of the stick and the duration of the speed glue effect, it is usually glazed.

The release of solvents in halls and changing rooms can cause health problems. The ITTF has banned the sticking indoors because of the health risk with effect from September, 2006. " Speed gluing ", which has been practiced by many players for many years , is no longer permitted under the ITTF rules since September 1st, 2008. However, this is permissible. "Tuning" the manufacturer of table tennis surfaces, however, volatile organic solvents (may VOC = V olatile O rganic C ompound) only up to a clearly defined upper limit ITTF with a RAE-meter detected in use of the racket. Such rubbers, which have a speed glue effect "built in" by the manufacturer, are called Tensor rubbers and are commercially available: (a) Butterfly Tenergy, (b) Formula donic, (c) Joola Tensor and (d) Andro Hexer, (e) Xiom Vega Pro.

Bat wood

The stick consists of several layers that are glued together. Layers of plastic can also be used, but the blade must be at least 85% wood. Hard types of wood such as B. walnut , mahogany , beech make the game faster and are therefore suitable for attacking players, soft woods such. B. willow , birch or poplar, however, are preferred by defensive players.

Modern, high-quality rackets are usually clever combinations of hard and soft woods. So one uses z. B. veneer cores made of the light and soft abachi (or balsa ), one or more barrier veneers made of hard or harder woods ( walnut , wenge ) and then again a softer outer veneer ( limba , koto or again abachi) and thus achieves stick woods that enable a very high speed of play without the technically skilled player having to forego his "feel for the ball" (as imprecise as this term may be).

The use of thin layers of so-called fineline veneers is particularly advantageous for the long-term freedom from warping and uniform playing properties of the racket - a block of many thin (0.5–1 mm) layers of Abachi or Koto veneers is then glued together across the Glue joint cut into slices again. The “veneer” actually consists of fine strips of veneer. The material is slightly heavier than the original material due to the glueing, but the playing properties - especially with regard to ball control - are very good due to the very uniform properties of these "veneers". Fineline veneers are also very popular in the grip area, because appealing visual effects can be achieved by using different colored glues (the stick shown, for example, has such a fineline grip).

In addition to the selection of the “right” wood, the quality and type of glueing also play an important role. When designing a new model, between 20 and 50 types of veneer are often manufactured, tested and then discarded until the club type finally meets the requirements of its developer.

One of the essential criteria in the development of rackets is the enlargement of the optimal hit zone, the sweet spot or sweet point. What is meant is the area of the club face in which the ball can be accelerated and controlled in the best possible way. The center of this optimal hit zone has not yet been predictable. Experienced material developers indicate that the center of this zone is somewhere between the center of the racket's center of gravity (photo: green point in the table tennis blade) and the geometric center of the blade (without the grip zone) (photo: red point in the table tennis blade). Investigations to determine the size and location of the optimal hit zone from a biomechanical point of view were carried out in 1970 and 1971 by Martin Sklorz, the then federal instructor of the DTTB, at the TU Braunschweig. The then developed rackets with "cut off" upper edge could not establish themselves on the market and disappeared from the offers of table tennis dealers after a short time.

The size of this optimum hitting area can by embedding carbon fiber , Kevlar fibers , or glass fibers are improved in the adhesive joint. The ball contact time is drastically reduced, which is then often at the expense of ball feel and spin. For a few years now, metal foils have also been embedded in the veneers for this purpose - this is actually not compliant with the rules, but has so far been tolerated by the ITTF .

Crucial for the playing characteristics of the stick wood is its vibration behavior. Wood that vibrates at high frequencies accelerates the ball more than wood that vibrates at low frequencies. The oscillation frequency of the stick depends on the veneer material, the size of the blade (the smaller, the higher the frequency) and the width of the blade bridge (this is the small - almost triangular - part of the blade that is not covered by the handle or the rubber). A large bridge leads to a higher frequency and thus to more speed.

After the improvement of the table tennis racket blade via the veneers only progressed in very small steps over the years, work began a few years ago on the improvement of the racket handles. There have always been attempts in the past such as B. handles pivoted to the blade axis, adjustable weight inserts - these constructions were ultimately not accepted by the TT players. Newer methods such as hollowing out and then foaming the handles, stiffening with carbon hollow rods or vibration damping with rubber inlays seem to be promising approaches and also accepted by the players.

Official approval of the surface

From January 1, 1982, only those racquet rubbers were allowed to be used in international tournaments that were approved by the table tennis world association ITTF . The approved coverings were given in a list: manufacturer, color of the covering, color of the sponge, type of covering (pimples inside or outside, long pimples, ...). An updated list is published twice a year, on April 1st and October 1st. In October 2019, the list contained more than 1,600 toppings.

Up to the year 2000 there was an official approval procedure for table tennis bats at the German Table Tennis Association DTTB . But this was abolished; since then, the ITTF's admission list has been binding. The permitted materials are precisely listed here. The DTTB only explains unclear provisions. For example, you must not use a dark sponge under a red translucent surface. A clearly visible ITTF symbol and ITTF trademark must be affixed to the surface on the edge of the face. In the national German game operation, any surface that was valid at the beginning of a season may be used throughout the season, even if it is no longer included in the new list that may appear during the season.

The racket in the table tennis rules

Section 4 of the rules manual deals with the table tennis bat. The following provisions are taken from this (as of: DTTB January 1, 2009).

- Size, shape and weight of the club are arbitrary. However, the sheet must be flat and rigid.

- At least 85% of the leaf, measured by its thickness, must be made of natural wood. An adhesive layer within the club face may be reinforced by fiber material such as carbon fiber, glass fiber or compressed paper. However, it must not make up more than 7.5% of the total thickness or more than 0.35 mm - whichever is less.

- One side of the reed used to hit the ball must either be covered with ordinary rubber pimples (pimples outwards, total thickness including adhesive not more than 2 mm) or with sandwich rubber (pimples inwards or outwards, total thickness including adhesive not more than 4 mm).

- Ordinary pimple rubber is a single layer of non-cellular (i.e. not sponge or foam) rubber - natural or synthetic - with pimples evenly distributed over its surface, at least 10 and not more than 50 per square centimeter .

- Sandwich rubber is a single layer of cellular rubber (i.e., sponge or foam rubber) that is covered with a single outer layer of ordinary knobbed rubber. The total thickness of the rubber studs must not be more than 2 mm.

- The covering material must completely cover the sheet, but must not protrude from the edges. The part of the sheet closest to the handle that is grasped by the fingers may be uncovered or covered with any material. ( Note: The ITTF referee manual gives a tolerance of ± 2 mm as a guideline for protruding or too small coverings. )

- The sheet itself, every layer within the sheet and every layer of coating or adhesive must be continuous and of uniform thickness.

- Both sides of the club - regardless of whether there is a coating or not - must be matt, namely bright red on one side and black on the other.

- The surfacing material should be used as approved by the ITTF; H. without any physical, chemical or other treatment that changes the playing characteristics, friction, appearance, color, structure, surface, etc.

- Slight deviations from the completeness of the covering or the evenness of its color, which can be attributed to accidental damage, wear and tear or fading, can be permitted, provided that they do not significantly change the properties of the surface.

- Before the start of the game and every time he changes his stick during the game, the player must show his opponent and the referee the stick he wants to play with and allow them to examine the stick. ( Note: Changing the club / surface during the game is strictly forbidden. Exception: The club was damaged during the game. Deliberate destruction or damage to the club or surface is excluded. )

Historical

Around 1900 people began to string the wooden club with parchment, fur or leather, later they used cork or sandpaper or played with an empty wooden club. In 1902 the rubber flooring appeared. According to a legend, the Englishman EC Goode bought headache pills in a pharmacy. When paying, coins fell on a rubber mat lying on the counter and jumped up. Goode acquired this rubber mat, stuck it on his racket, and subsequently played successfully with it. Contrary to the truth of this legend, the London sporting goods manufacturer Frank Bryan applied for a patent as early as 1901 for a “bat covered with a thin piece of rubber” (Patent No. 25276). William Laird filed a similar patent a little later, on January 21, 1902.

When the world association ITTF was founded in 1926, practically every club was allowed in the rules:

"THE RACKET: The racket may be of any material, size, shape or weight, provided it be not white, light-colored or reflecting.

The racket can be made of any material, size, shape or weight, but it must not be white, light or reflective. "

With the advent of the sponge in the 1950s, intense discussions arose around the world about the permissibility of this material. As a result, many national associations banned this surface. In 1957 the DTTB followed these bans:

“Only pimple rubber can be used as a covering, with a total covering height of no more than 2 mm. The pimple rubber must be glued directly to the wood of the club. In addition, the knobs must be directed outwards and must not be more than 50 pieces and not less than 10 pieces on the square cm. "

various

- The hand holding the club becomes the club hand and may also be used for strikes below the wrist. This means that the ball can be returned with this hand, for example because the player misses the ball with the stick. The basis is Section 5.7 of the Table Tennis Rules, Part A: A player hits the ball if he touches it with the racket held in his hand or with the racket hand below the wrist during play.

- Regardless of the type and hardness of a stroke as well as the surface of the racket, the ball has contact with the racket for about a millisecond.

- The size, shape and weight of the club are no longer regulated. Theoretically, you can play with a racket the size of a tennis racket. This was different in the first published rules from 1924: The club diameter must not exceed the net height of 17½ cm. The stick handle can be chosen as long as you like. So-called hollow clubs, which are clubs covered with fur or parchment, were banned.

- The color specifications of the coverings must be strictly adhered to. Even a handwritten autograph makes a covering impermissible.

- Above a certain amount of damage (e.g. due to edge hits), a surface is no longer permitted for competition.

- At the 1951 World Championships , the Austrian Waldemar Fritsch defeated several world-class players by applying foam rubber instead of the usual pimple rubber, making the kickback inaudible.

- Karlheinz Schreiner was one of the first in Germany to use a sandwich racket, with which he won the Saarbrücken championship in 1957.

Every table tennis bat is unique

Every table tennis bat is unique. This results from the countless possibilities that are possible through the variation of different club woods with club coverings (with different sponge thicknesses). But a number of other factors also play a role. The surface adhesive used, how often a surface has already been glued, whether and how the speed gluing process is used, the age of wood and coverings, whether the wood is varnished or not, humidity, temperature and a few more all influence the behavior of a table tennis bat. In addition, despite all efforts to standardize the manufacturer, each piece of wood is unique. If the veneers are made from end grain , the racket will be a little heavier and faster. When producing the veneers, there are also slight deviations in the veneer thickness, which are often clearly noticeable in the playing behavior.

This leads to the fact that - after some time in play at the latest - two clubs with the same woods and the same coverings can have different playing characteristics. The changeover when changing clubs is therefore more of a problem for most players. In tennis or squash, it is relatively easy to have one or more spare rackets ready, whereas in table tennis, changing rackets during a competition (e.g. due to a broken racket) is usually an enormous disadvantage for the player.

The wood of the stick is a living product and changes greatly over time, in many cases for the better. Even cheap but old “department store bats” can get such good prices from collectors. Even if you wait a long time, an absolutely cheap racket with a blade that is more like cardboard than veneer quality does not turn into a wood suitable for competition. The fact that many competitive and top players play relatively old woods is more due to the extreme familiarization with the material and the great sensitivity of the players.

literature

- Liang Geliang : The application of the combination racket , DTS magazine , 1981/6 page 63-64

- Rahul Nelson: Report from the club factory , description of how a club is made. DTS magazine , 2000/7 pages 12-17

- Dietmar Kelkel: The key point , DTS magazine , 2004/5 pages 34–35

- Long knobs , table tennis magazine , 2009/2 pages 8–15

- Jörg Petrasch, Konrad Tiefenbacher: Keeping in touch (physics in the interplay of bat and ball), table tennis magazine , 2010/1 page 51

- Jörg Petrasch, Konrad Tiefenbacher: Something is spinning - every table tennis player uses the Magnus effect , tischtennis magazine , 2010/6 page 51

- Jörg Petrasch, Konrad Tiefenbacher: The mystical connection. The vibrations of the stick wood are measurable - but not which player will be happy with which wood , table tennis magazine , 2010/7 page 43

- Jörg Petrasch, Konrad Tiefenbacher: Contrary to what we thought - sticky rubbers no longer generate spin. Other factors determine the reversal of rotation , tischtennis magazine , 2010/10 page 58

- Rahul Nelson: Short Knobs - The Underestimated Species , table tennis magazine , 2010/5, pages 38–39

- Jörg Petrasch, Konrad Tiefenbacher: A Ferrari is not [sic] against it , table tennis magazine , 2010/11 page 50

- Jörg Petrasch, Konrad Tiefenbacher: The spiders, the players - an invisible power shapes the game: the rotational energy , table tennis magazine , 2010/12 page 42

- Jörg Petrasch, Konrad Tiefenbacher: The speed is overestimated , tischtennis magazine , 2011/1 page 50

Individual evidence

- ↑ DTS magazine , 1984/7 page 36

- ↑ DTS magazine , 1988/4 page 48

- ↑ tischtennis magazine , 2019/5 page 31

- ↑ Table tennis without foam rubber . In: Arbeiter-Zeitung . Vienna April 5, 1959, p. 28 ( berufer-zeitung.at - the open online archive - digitized).

- ↑ DTS magazine , 1998/7 page 7

- ↑ tischtennis magazine , 2009/2 page 8

- ↑ DTS magazine , 1999/1, page 32

- ↑ Guideline on racket tests in the DTTB, page 3 (accessed on September 30, 2019)

- ↑ List of club materials, TT Blades Database on stervinou.net, accessed on February 19, 2018.

- ↑ ITTF record: More than 1,600 rubbers on the approval list Report from October 11, 2019 (accessed on October 15, 2019)

- ↑ DTS magazine , 2001/9 page 38

- ↑ tischtennis magazine , 2009/3 page 45

- ↑ Table tennis rules A ( Memento from January 17, 2009 in the Internet Archive )

- ↑ Thomas Matzke: Effects of the rule changes in table tennis with special consideration of the medial effectiveness of the sport , page 7, master thesis at the Ernst-Moritz-Arndt-University Greifswald from September 7th 2008 “Effects of the rule changes in table tennis with special consideration of the medial effectiveness of the Sports " ( Memento from November 21, 2015 in the Internet Archive ) (PDF; 3.1 MB)

- ↑ Hella von Sinnen and the legend of the first covering , report from July 16, 2013 (accessed on July 16, 2013)

- ↑ The Table Tennis Collector, issue 47, page 10 ( Memento from March 5, 2016 in the Internet Archive ) (accessed on July 16, 2013; PDF; 3.2 MB)

- ↑ William Laird's patent (accessed July 16, 2013)

- ↑ SUMMARY REVIEW OF THE PROBLEM OF RACKET STANDARDIZATION; by Ivor Montagu , President International Table Tennis Federation, July 1st, 1958 Online Page 3 ( Memento from May 12, 2014 in the Internet Archive ) (accessed May 9, 2014)

- ↑ Regulations with Michael Keil - Point 04/05 ( Memento from March 27, 2013 in the Internet Archive ) (accessed on November 1, 2011)

- ↑ Table tennis rules part A ( Memento from April 30, 2015 in the Internet Archive ) (accessed on November 7, 2011; PDF; 277 kB)

- ↑ tischtennis magazine , 2010/1 page 51

- ↑ DTS magazine , 1955/13 page 14 + 1957/1 West issue page 14

- ^ DTS magazine , 1951/21 issue west-south, page 3

- ↑ DTS magazine , 1999/12 page 20

Web links

- Approved rubbers for table tennis bats (PDF file). Valid from April 1, 2008 to September 30, 2008, in German games also until June 30, 2009 (176 kB)

- Approved rubbers for table tennis bats (PDF file). Valid from October 1, 2008 to March 31, 2009, in German games also until June 30, 2009; All surfaces on List 29 and 29b are permitted in German gaming operations . (531 kB)

- Noppen-Test.de (information about long pimples)

- Table tennis tips for long pimples, short pimples and anti-top - table tennis technique, table tennis tactics

- Technical Leaflet T4 (ITTF technical description T4 for table tennis bats) (PDF file; 513 kB)