Electric power supply on ships

The on- board network for the electrical energy supply on ships is an island network , which is usually fed by ship diesel engine generators , shaft generators or, more rarely, by smaller turbo generators .

development

The historical development can be divided into the following three phases:

Lighting and signal transmission

In the 1880s, the introduction of electrical engineering began with lighting, incandescent lamps were used instead of petroleum lamps . The invention of the carbon arc lamp by H. Davy in 1809 was used for street lighting ; it was mainly used in headlights on ships . In 1879, Edison was granted the patent for a carbon filament light bulb, which was called the first usable light bulb. Electric lighting was first used on ships as early as 1880, for example on the Columbia with a total of 115 lamps. The Werra , a Lloyd express steamer of the river class , received electrical lighting in 1883.

This was followed by the electrical signal transmission for radio operation , for bridge and machine telegraphs and the on- board telephone . As a result, individual auxiliary machines were also converted from steam to electric, initially with direct current . The development accelerated with the growing ship sizes and expansion of the facilities until around the end of the First World War in 1918.

Auxiliary machines

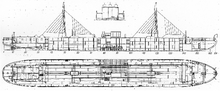

From 1904 the first diesel-electric propulsion systems were used on the 1000-ton tankers Vandal (ship) and Ssarmat . Since the pioneering generation of diesel engines could not be reversed, reverse driving was implemented with the help of electrical engineering; on the Vandal according to the “del Proposto” principle (only diesel-electric driving in reverse). On the Ssarmat it was a pure diesel-electric drive.

From 1918 onwards, steam was gradually displaced as an energy source for auxiliary purposes through extensive electrification of the on-board systems in the course of the development of motor ships. The electrical energy was initially generated by steam-powered machines ( piston steam engine , steam turbine ) which, with the increasing use of diesel engines as propeller drives, are also being replaced by diesel engines for generator drives.

Increase in electrical power, around 1930 the emergence of larger diesel and turbo-electric propeller drives and thus the introduction of three-phase current on ships with three-phase propeller drives. Deck machines such as anchor winches , mooring winches and loading winches are increasingly being driven by electric DC motors instead of steam engines.

Three-phase alternating current

After the Second World War , three-phase alternating current (three-phase current) with a frequency of 60 Hz is introduced into the vehicle electrical system . Up until 1965, the increase in speed of modern ships and the emergence of new types of ships such as tankers , bulk carriers with large carrying capacities and container ships resulted in a further increase in the installed electrical power for the on-board network. There are special developments for electrically operated loading and unloading devices, for the operation of integral refrigerated containers and, as a result, a further displacement of the direct current and the breakthrough to the three-phase electrical system. New ships received three-phase electrical systems from around 1960. Leonard converters or pole-changing three-phase motors are used for the winches . Due to the advances in power electronics , frequency converters are also used for winch drives from around 1990 .

Three-phase asynchronous machines have displaced steam or direct current machines to drive auxiliary machines such as fans , pumps , air compressors , refrigeration machines and winches . In cruise ships and some other special ships, the propeller drive is also carried out by electric motors. Comprehensive and powerful electrical systems with outputs of up to 100 MW , which are fed by five to ten diesel generators, are required.

Four diesel generators with a total output of around 15 MW were installed in the on-board network on merchant ships with many refrigerated containers, such as the Monte class of the shipping company Hamburg Süd .

E-balance sheet

An e-balance is used to estimate the expected electrical power requirement for various operating conditions (lake, district, port, possibly summer and winter operation, with and without refrigerated containers). In addition, the simultaneity factor determines whether it is a permanent or a short-term consumer. In addition, a distinction is made between important, unimportant and emergency consumers. The electricity producers are selected on this basis. As a rule, the electrical system is designed for a voltage of 440 V and a nominal frequency of 60 Hz.

For outputs of 8 MW or more , the medium voltage has advantages of 6.6 kV to 10 kV and is used on passenger ships and large container ships with many refrigerated containers. In the container ships in particular, the installed electrical output has increased considerably in the last 20 years. On the one hand, ever larger ships of this type are being built, so that the need for electrical energy for normal ship operation alone increased. Even more, however, the demands for ever greater transport capacity for refrigerated containers have led to an increase in electrical output to over 15 MW.

On the consumption side, if the refrigerated containers are neglected, the pumps and fans represent the largest consumer group. This is followed by the bow and stern thruster (s), which, however, are only to be taken into account in the area operation. The air conditioning must be considered depending on the ambient conditions and the type of ship. On ferry and cruise ships, they are among the largest consumers of electricity, followed by lighting.

Selection of the generator drives

As a rule, three to four auxiliary diesel generator sets are used. Auxiliary diesels are medium-speed (720–900 / min), rarely high-speed four-stroke diesel engines (1,200 - 1,800 / min). The speed results from the selected frequency and number of pole pairs.

In addition to the auxiliary diesels, a shaft generator is often installed, which is driven by the main engine via the main shaft directly or via a gearbox .

Gas and steam turbine generators are rare on motorized commercial ships. Steam turbo generators were often used in steam-powered ships in the past. Since steam turbines no longer play a role in ship propulsion in the civil sector, steam turbine generators have largely disappeared there. Gas turbo generators are the exception on merchant ships. You will e.g. B. used on the cruise ships of the Millennium class of the shipping company Celebrity Cruises .

Because of the high fuel prices, large waste heat boilers are installed downstream of the diesel engines and are generally referred to as exhaust gas boilers in ship technology . This is used to produce superheated steam from the heat of the exhaust gas, which generates electricity in a steam turbo generator. So has z. For example, the shipping company Maersk Line also uses the container ships of the Emma Mærsk class, with 11,000 (13,000) TEU, formerly the largest in the world, equipped with gas and steam turbine generators to utilize waste heat. The hot exhaust gases from the main engine are used: the gas turbine receives a partial flow of exhaust gases directly from the main engine's exhaust manifold. A steam turbine is located on the same shaft, which is fed with superheated steam from an exhaust gas boiler. Both turbines are connected to the generator via gears, which can provide up to 8 MW in nominal operation.

Pleasure craft

With sport boats, relaxation is often the focus. Constant engine noises and exhaust gases are annoying, especially at anchor or in harbors.

While the engine with a connected alternator for the power supply is always available in motor boats, at least while the boat is in motion , sailing yachts have to get along over long distances without any energy supply from the main engine. While sailing, the electrical consumers are fed by accumulators. The more luxurious the yacht is furnished, the higher the power consumption. As a minimum, the navigation equipment (GPS, plotter, wind measurement system), the radio and, at night, the lights must be supplied with energy. Electric winches , pressurized water pumps, autopilots, and refrigerators are common on seagoing yachts today, but they consume a lot of energy. For this reason, alternative generators for alternative energy sources, including solar cells, hydrogen generators or wind generators, are widespread, especially in sailing boats.

Energy supply in port operations

Except in shipyards electric power in most ships in the harbor by the board is produced diesel generators. In order to reduce the exhaust gas and waste heat pollution from the auxiliary diesel generators running for this purpose , it is discussed to supply ships in the port via a shore connection. The first installations were put into operation in 2008 in the ports of Kemi , Gothenburg and Lübeck . The connection is often made at medium voltage level . The intention is to fix the voltages of 6.6 kV and 11 kV in a future standard.

In contrast, shore sockets are now standard in marinas for pleasure craft. On the jetties, 230 V sockets (usually with so-called caravan plugs ) are attached at regular intervals , to which the boat's charger is connected with a cable that is carried along. This allows the ship's batteries to be recharged without the engine having to run.

Web link

- G. Ackermann, K.-H. High-rise: Electrical systems on ferry and cruise ships Hansa, No. 3/2012, on the website hochhaus-schiffsbetrieb.jimdo.com

literature

- W. Droste, K.-H. High-rise: Reduction of the electrical energy consumption on merchant ships. In: Hansa . No. 11, 1987.

- H. Harer, K.-H. High-rise building: methods for saving energy in on-board networks. (= Handbook of the shipyards. Volume 20). Shipping company Hansa, 1990.

- G. Ackermann: electrical engineering. In: Handbuch Schiffsbetriebstechnik. Seehafen Verlag, 2006, ISBN 3-87743-816-4 .

- R. Witthohn: Emma Maersk - largest container ship in the world underway. In: Ship & Harbor . No. 11, 2006.