Plasma screen

A plasma screen (English PDP for Plasma Display Panel ) is a color flat screen that generates the differently colored light with the aid of phosphors that are excited by the plasma generated by gas discharges .

Plasma screens are mainly used as large (from 42 inch screen diagonal ) television display devices. Here they compete with liquid crystal displays ("LCD"); Cathode ray tubes have rarely been built in such sizes.

functionality

Plasma (from the Greek "structure") is ionized gas that contains neutral particles as well as free ions , excited atoms and electrons . Plasmas emit visible light and ultraviolet radiation due to the spontaneous emission of excited atoms .

In the case of a plasma screen, the emission of UV rays from a low-pressure plasma is used. The way it works is similar to that of a fluorescent lamp . In such lamps, fluorescent materials are excited to emit visible light by ultraviolet radiation from the mercury vapor plasma. In contrast, noble gases are used in plasma displays .

Structure of the color screen

There are many small chambers between two glass plates. In the color screen, three chambers each result in a picture element, a so-called pixel .

Each of the three chambers lights up in one of the three basic colors red , green and blue . The colors are created by additive color mixing , i.e. by mixing the three basic colors (e.g. yellow by mixing green and red light, which is achieved in the plasma screen by the lighting of the corresponding chambers). Each chamber is filled with an inert gas mixture of neon and xenon , whereby the pressure is considerably lower than normal air pressure , so it is an "almost vacuum". Some manufacturers also add helium . The proportion of xenon is approx. 3% to 5%.

To generate an image, each chamber is individually "ignited" with an associated transistor . This means that the gas is ionized for a short time, it becomes plasma . The basic colors in the chambers are generated by various phosphors as soon as the ultraviolet radiation ( vacuum-ultraviolet range, 140 to 190 nm) emitted by the plasma hits the phosphors. The ultraviolet itself is not visible. The phosphors convert the VUV radiation into visible light with a different color depending on the phosphor.

Each color is produced by a different phosphor: BaMgAl 10 O 17 : Eu 2+ (blue), Zn 2 SiO 4 : Mn 2+ (green) and (Y, Gd) BO 3 : Eu 3+ (red; can also be from Y (V, P) O 4 : Eu 3+ or Y 2 O 2 S: Eu 3+ ). In order to not only generate the discrete states "on" (ignited) and "off", but also to generate brightness levels in between, the chambers are ignited at short intervals (intervals). The duration of an ignition is varied in order to vary the brightness. The longer a chamber is ignited, the brighter it glows.

The gas between the two glass plates is very dilute, which means that low plasma temperatures are possible. For ignition, voltages of a few hundred volts are required. On the lower dielectric layer (glass plate, i.e. an insulating layer) sits a row / address electrode strip which, together with the upper row electrodes , enables each chamber to be controlled (each chamber sits at the intersection of an address and an upper electrode). The luminescent material (applied to the dielectric layer and the barriers) and the gas mixture or the plasma are located in the chamber itself. A protective layer has the task of protecting the upper dielectric layer and the transparent electrodes located there. Due to the protective dielectric layers, the two electrodes can only generate a gas discharge in the chamber with a pulse applied to them - the pulse parameters determine the brightness of the emitted color.

Plasma screens are manufactured using a sandwich construction.

The address electrodes are arranged vertically and the line electrodes are arranged horizontally. The resulting grid (also called matrix) can be used to control the individual chambers using the multiplex method. While only one row could be controlled with only one electrode layer, with a grid (each crossing point corresponds to a chamber) it is possible to control each chamber separately.

The blue phosphor has a lower stability under VUV radiation.

history

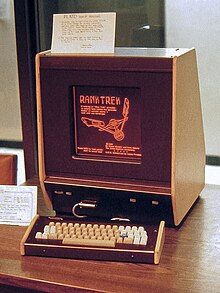

The first functional plasma screen was developed in 1964 by Donald L. Bitzer and H. Gene Slottow for the main computer system Plato IV of the University of Illinois . Plasma screens had the advantage over CRT screens that they could be controlled digitally; they were also quite durable and space-saving. Plasma displays were therefore widely used in the mainframe sector for a number of years. Monochrome plasma screens or displays, like the shown plasma monitor of the PLATO V, do not use different colored phosphors in contrast to color plasma screens. Only one chamber is used per pixel, which is filled with the noble gas neon . This results in the orange-red color. The way it works is based on the glow discharge and is identical to that of a glow lamp .

However, technical progress and reduced production costs helped the CRT monitor to break through as a computer display unit in the 1970s . Plasma screens have only been used for a few special purposes since then.

When the first laptops were developed at the beginning of the 1980s , some early manufacturers, including GRiD , Toshiba and Chicony Electronics , resorted to plasma screen technology to equip their portable computers, as it enabled very flat and compact housing shapes with an appropriately large screen diagonal was far superior to the first liquid crystal screens from an ergonomic point of view (viewing angle, contrast). However, the high power consumption of the plasma displays made off-grid operation largely impossible; In addition, their use was limited to expensive devices for reasons of cost. Since high-resolution color plasma screens could not be technically realized and great progress was made in the development of better LCDs, plasma laptops disappeared from the market around 1990.

At around the same time, several consumer electronics companies began developing color plasma screens for televisions . The first color plasma display with a screen diagonal of 21 inches was introduced by Fujitsu in 1992 ; It took a few years for displays to be ready for the market.

Pioneer launched the first plasma screen television in 1997. The 1998 Winter Olympics contributed to the commercial breakthrough for the technology : At that time, a Japanese television station needed large flat screens for its in-house HDTV range .

properties

Principle-related advantages of plasma technology are the almost unlimited vertical and horizontal viewing angles without color or contrast impairment and the extremely short response time of the individual image cells, which is in the nanosecond range.

For a long time, the higher contrast was considered to be the main advantage of plasma screens. However, this is no longer generally applicable today. The static contrast of current plasma televisions varies between 500: 1 and 18,000: 1 depending on the device; the static contrast of LCD televisions also varies greatly from device to device and can now be between 500: 1 and 6,000: 1. Due to the higher image brightness, LCD devices can also be perceived subjectively as having a higher contrast, especially during the day.

It used to be stated that plasma displays visibly lose their luminosity after an average of 30,000 hours (which led some prospective buyers to lean towards an LCD); today (2011) a value of 60,000 hours is given.

In contrast to LCD televisions, the power consumption of a plasma screen depends heavily on the image displayed and is dynamic: a dark subject uses significantly less electricity than a bright one.

According to reports from radio amateurs , plasma screens emit broadband electromagnetic radiation that disrupts reception in the medium and short wave range in the immediate vicinity . Unlike tube devices, they are insensitive to magnetic fields . This is why speaker systems with unshielded magnets can be placed directly next to the screen without causing picture interference.

Market situation

In the field of televisions, plasma screens no longer play a role compared to LCD TVs on the market, since Panasonic , LG and Samsung were the last manufacturers to stop producing plasma TVs in 2014 .

In 2007, of the 4.4 million flat screens sold, 3.9 million were LCDs. In 2012 the market share of plasma screens was only 5.7%. This corresponds to a decrease compared to 2011 of 23%. The small market share was also due to the fact that plasma screens were only offered from a size of 42 " (about 106 cm).

At the beginning of 2008, the TV manufacturer Pioneer announced that it would also offer LCD TVs in the future and no longer manufacture its plasma panels itself and would purchase them from Panasonic (Matsushita) in the future. In September 2008, Hitachi also announced that it would discontinue panel production. After Pioneer announced in February 2009 that it would completely cease production of plasma and LCD televisions, Panasonic remained the last Japanese manufacturer of plasma TVs. But Panasonic also stopped its production of plasma televisions at the end of March 2014. Korean manufacturers LG and Samsung took the same step at the end of 2014.

While Panasonic was still the world's largest manufacturer of plasma displays in 2009 (39% market share; it was followed by Samsung with 31% and LG with 22%), its market share in 2012 was only 16.5% and thus far behind its main competitor Samsung ( 51.9%).

Alternatives to plasma screens

Possible alternatives to the plasma screen depend heavily on the intended use.

As "normal" televisions, LCD televisions with CCFL or LED backlighting are a frequently chosen alternative. Conventional CRT screens ( Cathode Ray Tube ) cannot be produced in such large formats because the screen mass (glass thickness) required to achieve mechanical stability increases significantly. With a given installation depth, convergence errors (color shifts) and linearity errors (distortions) are increasingly difficult to control.

For large screens, an alternative is projection ( beamer ) onto a white wall or a special screen. The images generated in this way have a lower contrast than the images of an LCD or even more than those of a plasma television.

In 2011, OLED screen technology became known through some smartphones.

Plasma Addressed Liquid Crystal (abbreviation PALC ) is a technology for flat screens that contains or combines elements of plasma screens and LCDs ( Liquid Crystal Displays ). It uses plasma switches (instead of transistors , as is the case with TFT screens ) to control an LCD screen.

literature

- LS Polak: Plasma Chemistry , Cambridge International Science Publications, 1998, ISBN 1-898326-22-3 .

- Michael Kaufmann: Plasma Physics and Fusion Research , Teubner, Stuttgart / Leipzig / Wiesbaden, 2003, ISBN 3-519-00349-X .

- David Macaulay, Neil Ardley : Macaulay's mammoth book of technology , Tessloff Verlag, Nuremberg 1988.

Web links

Individual evidence

- ↑ Plasma TV market

- ↑ Paul D. Sergi: Plasma TV - Mother of All RFI Producers . eHam.net, November 27, 2002; Retrieved September 12, 2009 (news item).

- ↑ TVI wrong - FUNKAMATEUR www.funkamateur.de, June 6th 2011, Accessed December 15, 2011

- ↑ Volker Briegleb: Consumer electronics industry continues to grow . In: Heise Online. February 21, 2008, Retrieved September 12, 2009 (news item).

- ↑ No desire for new televisions In: elektroniknet.de. March 22, 2013. Retrieved December 25, 2013

- ^ Nico Jurran, Jan-Keno Janssen: Report: Pioneer no longer produces plasma displays . In: Heise Online. March 7, 2008, Retrieved September 12, 2009 (news item).

- ↑ Matsushita takes over plasma production from Pioneer . In: Heise Online. April 25, 2008. Retrieved December 25, 2013.

- ↑ Ulrike Kuhlmann: Hitachi gives up plasma panel production . In: Heise Online. September 18, 2008, Retrieved September 12, 2009 (news item)

- ↑ Pioneer discontinues television production . In: Heise Online. February 7, 2009. Retrieved December 25, 2013.

- ↑ a b handelsblatt.com, Five years in the red: Panasonic parts with plasma televisions. October 9, 2013, accessed December 19, 2013 .

- ↑ Michael Söldner: LG stops production of plasma TVs in November. In: PC world. October 29, 2014, accessed March 28, 2018 .

- ↑ David Katzmaier: Samsung to end plasma TV production this year ( English ) In: Cnet . July 2, 2014. Retrieved March 28, 2018.

- ↑ Source: Press release April 28, 2009 from displaysearch.com

- ↑ OLEDs for smartphones continue to be popular and expensive In: Heise Online. April 12, 2012, Retrieved December 25, 2013