Bookbinding

When bookbinding is called the last operation of book production after completion of the printing work . It includes all the steps from arranging and joining the pages or layers of a book to providing the book block with a cover and the subsequent decoration.

Bookbinding also refers to the manual processing of an existing book, s. Bandage .

history

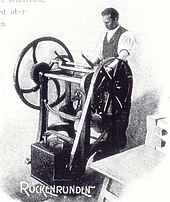

While books to bind to the 19th century, a purely artisanal activities was (hand cover), is produced today, much of the production in industrial scale production ( Verlag cover ). The basic processes have remained the same, but they differ significantly in their execution. The artisanal bookbinder carries out all the work steps one after the other and uses only a few hand-operated tools, so he makes the cover completely himself. Even the artistic design often comes from the bookbinder. In manufaktur like organized binderies from the 19th century one was division of labor made. Individual work steps were mechanized . With the emergence of steam bookbinding in the 19th century, the division of labor and mechanization increased. In industrial book production from the middle of the 19th century, most of the work steps were gradually carried out by machines. This is the only way to make larger editions possible. The artistic design is done by a graphic artist . The bookbinder is often only responsible for the operation and the smooth flow of a single work step.

Process of manual bookbinding

Sheet processing

Leveling and hitting

Up to the middle of the 19th century, printed sheets had to be glued afterwards, as the printers mainly used unsized or only slightly glued papers , which absorbed the color better. Gluing , however, made the finished book more durable and protected the pages from moisture, so it was up to the bookbinder to make up for this failure. To do this, the bows were first pulled through the so-called leveling water, a hot solution of animal glue and added alum (aluminum potassium sulfate dodecahydrate), in order to be air dried on horsehair strings. This was followed by beating - smoothing the papers with a heavy hammer. In order not to damage the arches, the direction and execution of the blows were precisely prescribed. These two operations were omitted when the sizing of the paper prevailed in the mass.

Fold the sheets and fold them again

The next step (or the first in modern bookbinding) is folding the sheets, that is, folding them according to the pagination . In the past, the youngest apprentice was usually responsible for this, as it is a simple job that can be done without great effort. With the so-called folder bone , the folds are cut down sharply. In order to achieve a uniform block thickness, the papers used to be beaten again before the alignment. In the course of the 19th century, however, it was replaced by presses or rollers in most manual binders. However, these could never achieve the same sharpness in the result as manual processing.

Preparatory work for the new binding

In today's manual binding it often happens that books are not bound for the first time, but rather because of damage or the owner's wish for a higher quality cover. In this case, detaching the book block from the binding and separating the staple are the top priorities . After that, glue residues have to be removed and the sheets have to be re- folded if necessary. The further work steps then correspond to those of an original binding.

Setting up the bow

Before stapling , any additions, previously especially cards, boards or stitches , must be glued in at the places provided. In addition, the connection of the attachments with the first and last arches, known in technical terms as attaching, is part of the preparatory work. The simplest endpaper consists of a double sheet the size of the layers, the front and rear endpaper are connected with an additional strip of paper, the attachment fold. In addition, there are a number of other types of attachment, all of which are constructed differently and are attached.

Book block formation

If not done earlier, the individual layers must be put together in the correct order immediately before stapling. This process is called collation . The check of the correct sorting and completeness has been used by the flutter marks since industrial book production .

When stapling, the individual layers are connected to the book block with the help of the stitching thread. This is still done today in manual binding by stapling on finished fabric tapes or with the help of a mechanical stapling machine using gauze . Books with real raised frets are stapled with the staple drawer, which was the usual procedure until the end of the 18th century and was gradually replaced by sawn-in frets in favor of a simplified stapling process. Today, on the other hand, handicraft bookmaking is mostly done with stapling on tapes, only with bibliophile books one falls back on stapling with real frets in individual cases. If, on the other hand, the bookbinder gets loose sheets to bind in, he uses adhesive binding . The modern industrial stitching process is called thread sealing .

Book block processing - gluing, trimming, rounding, pressing and backing

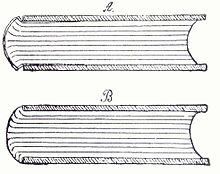

In order to achieve a continuous connection of the sheets in the spine and to prevent the outer layers from shifting, the book spine is first glued after stitching. For this, glue is applied thinly with a brush and then rubbed into the gaps between the layers with a hammer fin or a folder. As an alternative, dispersion adhesives , hot melt adhesives or adhesives based on polyurethane (PUR) are also used today for gluing in modern books . Only adhesives of vegetable or animal origin are used for historical or otherwise valuable volumes in order to exclude adverse chemical and mechanical long-term effects. After drying, the book block is trimmed, i.e. all three book pages are brought to the same final format. This used to be done with the trimming planer , but is now also used in manual binding by smaller, manually operated and often electrically driven cutting machines. With demanding binding work, the head and foot are only trimmed after rounding and pressing.

The next step is to round the book block on the spine. For this purpose, the book block was (and is still today in smaller businesses) placed on a solid base and hammered into the desired curve. Larger companies sometimes work with back rounding machines. In order to bring the incline in the fold created by the stapling into a stable setting, the book block is then pressed off. To do this, it is wedged between two boards and the slightly protruding back is carefully folded over the board edges. A distinction is made between pressing on flat (45 °) and the deep (90 °) fold required for the binding with attached covers . The last steps in processing the book block are gluing the stapled book spine back and attaching the headbands. Depending on the weight of the book, molton , gauze or even tear-resistant paper is used for the backing . In the Middle Ages and early modern times , however, parchment waste was often used.

Decorating the bookcuts

The possibilities of pattern decoration were and are diverse. Depending on the era and region, the cuts were all around or on one side, monochrome or multicolored, marbled, speckled or provided with metal cuts . They could also be patterned or lavishly hallmarked . Painted cuts and other rarer types of decoration were also possible. While in the 19th century the three-sided decoration was still common for well-stocked books, including publisher's covers , today it is usually only, if at all, the color cut at the head of the book.

Attaching the capitals

The capitals at the top and bottom of the spine had to the Middle Ages the function to strengthen the book block addition and to prevent tearing of the layers. They were created as part of the stitching at the point where the stitching thread passed from one layer to the other. From the 14th century onwards, capital was made more decorative, by sewing it with different colored ribbons or braiding with colored leather straps. Since the introduction of the Fitzbund , it only had a decorative function, it was pricked separately around a strip of parchment or leather and stuck on the back. From 1700 to today's conventional woven started headbands to develop that only need to be cut and also glued to the book block.

Manufacture and attachment of the book cover to the attached tape

For the attached band, which is manufactured directly on the book block, the frets were or are initially attached to the book covers, depending on the attachment method - either pulled through, glued or connected to one another by an additional seam. After cutting to size and any further processing steps that may be necessary on the cover material , such as soaking, sharpening and thinning the leather , the upholstery follows. The cut-to-size cover material, the so-called panel, is coated with paste , possibly a back insert is attached, and then pulled tightly around the book cover. The protruding edges are tucked in and glued. The handling in the production of a half band differs only slightly from that of the full band . Here it is initially only the back that is covered, followed by the book covers, which are usually wrapped in paper, and any decorations on the front edges or cover corners.

The last step is the boarding up, the connection of endpapers and book covers. A distinction is made between the usual pasting, in which the endpapers are coated with glue, the book is closed and then pressed in, and the open pasting, in which the smeared endpapers are pulled onto the open cover, rubbed into the fold and then dried out when open .

Manufacture and attachment of the book cover to the cover band

The cover tape is often used in assortment bookbinding, especially for library bindings. To do this, all elements of the cover, the two book covers, the spine insert and the cover material are cut by hand. The panel is then smeared with glue, and the three shaping elements are glued to the flat surface centrally and at a distance of the fold width from one another. Any protruding material is wrapped in and glued. The connection with the book block is then done by so-called hanging. To do this, the paper sleeve glued to the back of the book block is first pasted and placed precisely on the corresponding cover back, the cover is folded over and the book closed. The paper sleeve is often omitted and the connection between the book cover and the book block is made by gluing the folds of the attachment. This is followed by pressing the book and then connecting the cardboard sheet from the endpaper or gluing a paper mirror to the inside of the book cover using glue. The last process now consists of pressing the book in again and drying these areas.

Decorating the book cover

The design of the book cover is done with the attached tape before boarding, with the cover tape before hanging. The history of book cover decoration knows innumerable variants and forms of jewelry, each with their own manufacturing techniques. The most common decorations in the European cultural area, however, were always blind embossing and gilding .

Process for industrial bookbinding

Sheet processing

arc

The printed sheets are either Rotabogen that in a low-pressure - or web offset press have been printed, or as flat sheets delivered (4 to 16 pages). Sheets must first be cut and then folded . Red sheets are already folded. Four-sided covers for stapled and perfect-bound catalogs are an exception. With adhesive binding , the envelope is processed flat (i.e. unfolded). With saddle stitching, there is a special feeder in which the flat-cut cover is folded directly in the machine.

Folding the sheet

The next step is to fold the sheets . The way in which the pages are arranged in relation to one another determines the folding system and thus also the folding machine . A distinction is made, among other things, between cross-fold folds, which are folded alternately at right angles , and parallel folds, which are split up again into spiral and zigzag folds. However, these variants can also be combined with one another, so that there are many different ways of folding a sheet. Immediately after folding, the sheets are pressed in so-called bundle presses in order to achieve the desired density and strength of the end product.

Setting up the bow

If inserts such as illustrations or cards on high-quality paper are to be enclosed with the finished book, these must now also be inserted by hand in the correct place in industrial production. In addition, in this work step the end caps are connected to the title and end sheet with the help of end-to-end gluing machines.

Book block formation

In this work step, the folded sheets are first laid over one another in the correct order or, in the case of thinner brochures, one inside the other. In this case, nesting and the subsequent step, stitching, are usually done in a single machine, the collective wire stitching machine. The mere collation of more extensive expenses, however, is a separate work step that can be carried out by a machine or manually. An important task that must be carried out in parallel to the steps mentioned above is the collation, the performance of a visual check. Since errors in the order of the sheets are not uncommon, the correctness of the collation carried out and the completeness of the sheets must be checked continuously. Depending on how the end product should be made, the book block is now connected mechanically by wire or thread stitching or adhesive binding .

Machine saddle stitching often involves sewing on gauze. If several threads have been used, they are connected to one another on the spine of the book by knots or with the help of thread sealing (Dutch).

Book block editing

Book block processing consists of several elements, depending on the type of stapling or adhesive binding. This includes gluing the back of the book block, which is used to additionally secure the folded sheets in the back, trimming on three sides, which can be followed by cut dyeing, then, if desired, rounding the block and gluing back the back with gauze or gauze material, the capital and the sleeve. These work steps can be carried out separately from one another in individual steps, with a separate machine for each work step, and in block processing systems that combine the steps.

Production of the cover

In the case of soft envelopes, the cover consists of a coherent piece of elastic cardboard or fabric, whereas in the case of hard cover covers it consists of four parts, the two covers, the back insert and the cover material . The materials and the method of working depend on the intended quality of the end product. First, the required parts are cut, the size being based on the dimensions of the book block and the type of later connection. The assembly to the finished book cover takes place separately. If the attachment, i.e. the connection of the book cover and book block, is done later by hand and there is a rounded spine, the spine insert must also be rounded manually at this point.

Book cover ornament

After assembly, the book covers are decorated with various forms of embossing, such as blind embossing , relief embossing or hot foil stamping (which also includes machine gilding ) using color or screen printing or, more rarely, forms of decoration such as inlay work or sticking illustrations.

Connection of book block and book cover

The final step in industrial book production is the hanging of the book block in the separately manufactured book cover. This can be done both by gluing the attachments to the book cover and by inserting the block into pockets provided on the inside of the book cover, although the gluing process clearly dominates. In some cases, the pad is glued not only to the book cover but also to the spine. If there is a sleeve , it creates the connection between the spine and the book cover. Depending on the number of copies , the format and scope of the work, the type and construction of the book cover and the hanging method, hanging is done either manually or on book hanging machines. This is followed by a final pressing. In the majority of the hardcover bandages, the fold is also burned in, the recessed line between the back insert and cardboard cover, which acts as a kind of hinge for easier opening.

Bandage

Reasons for changing an already existing cover and book block can be:

- Repair or replacement of a defective cover and book block

- Replacement of a simple binding with a splendid binding

- Replacing the soft cover of a brochure with a hard cover, for example in the case of library covers

- Standardization of the appearance of a library, for example in baroque libraries

- Summary of several works in one volume (bundle)

- Improvement of the manageability, for example by ring binding in music books

The removal of a book cover of the book block is used as a setting referred to.

See also

literature

- Paul Adam: The book cover. Its technology and its history (= Seemanns Kunsthandbücher 6, ZDB -ID 53757-3 ). Seemann, Leipzig 1890 (reprint with an afterword by Walter Bergner. Saur, Munich et al. 1993, ISBN 3-598-07270-8 ).

- Severin Corsten (Ed.): Lexicon of the entire book system. Volume 6: Phraseology - Schütz-Hufeland. Hiersemann, Stuttgart 2003, ISBN 3-7772-0327-0 .

- Hellmuth Helwig: Handbook of the binding customer. Volume 1. Maximilian Society, Hamburg 1953.

- Hellmuth Helwig: Introduction to Binding. Hiersemann, Stuttgart 1970, ISBN 3-7772-7008-3 .

- Thorvald Henningsen: The manual for the bookbinder. 2nd edition. Hostettler, St. Gallen 1969.

- Paul Kersten, Ludwig Sütterlin: The exact book cover . Verlag von Wilhelm Knapp, Halle ad Saale 1909. (In the digital offer of the University Library Weimar. [1] )

- Paul Kersten: The exact book cover. 2nd increased and improved edition. Published by Wilhelm Knapp, Halle ad Saale 1912.

- Vasco Kintzel: Perfectly bind books yourself. Design and professionally bind books, photo albums, brochures, notebooks, sketchbooks, notebooks, block books, drawing books, notebooks, magazines, diaries and scrapbooks yourself. Books on Demand, Norderstedt 2005, ISBN 3-8334-3583-6 .

- Jean Loubier: The book cover from its beginnings to the end of the 18th century (= Monographs of Applied Arts 21/22, ZDB -ID 501163-2 ). 2nd revised and enlarged edition. Klinkhardt & Biermann, Leipzig 1926.

- Otto Mazal : Binding customer. The history of the book cover (= elements of the book and library system 16). Ludwig Reichert Verlag, Wiesbaden 1997, ISBN 3-88226-888-3 .

- Dag-Ernst Petersen (Ed.): Bound in the steam bookbindery. Bookbinding in the course of the 19th century (= Wolfenbütteler Schriften zur Geschichte des Buches 20). Harrassowitz, Wiesbaden 1994, ISBN 3-447-03507-2 (Therein especially: 1) Dag-Ernst Petersen: The handcrafted practical bindings. P. 99–111 and 2) Ernst-Peter Biesalski: The development of industrial bookbinding in the 19th century. Pp. 61-99).

- Technology of book covers and brochures. 2nd improved edition. Fachbuchverlag, Leipzig 1984.

- Wolfgang Wächter: Book restoration. The basic knowledge of the book and paper restorer. 3. Edition. Fachbuchverlag, Leipzig 1987, ISBN 3-343-00349-2 .

- Fritz Wiese: The book cover. A working customer with work drawings. 7th edition. Schlueter, Hannover 2005, ISBN 3-87706-680-1 .

Web links

- The German bookbinding museum in the Gutenberg Museum Mainz

- Bookbindery Wiki - Tutorial of the Central Technical Committee for Vocational Training in Printing and Media

- Lexicon of print processing

- Lexicon and technical terms in bookbinding

Individual evidence

- ^ Biesalski: Planing . In: Lexicon of the entire book industry . Vol. 6.

- ^ Biesalski: The development of industrial bookbinding in the 19th century. P. 68.

- ↑ Ibid. P. 70.

- ↑ Henningsen: The manual for the bookbinder. P. 108.

- ↑ Ibid. P. 109 f.

- ^ Biesalski: The development of industrial bookbinding in the 19th century. P. 80.

- ↑ Helwig: Introduction to binding knowledge. P. 28.

- ↑ Henningsen: The manual for the bookbinder. P. 126 ff.

- ↑ Petersen: The handcrafted utility bindings. P. 105.

- ↑ Ibid. P. 108.

- ↑ Kersten. 1912. p. 55

- ↑ The entire section on industrial book production is based on Bendig: Technology of book covers and brochures.