Drol's hammer brake

The Drolshammer brake was an automatically acting and multi-release compressed air brake for freight trains , which also on steep transit routes in mountainous terrain, such as. B. the north-south axis on the Gotthard could be used. In contrast to the Kunze-Knorr-Bremse , the Drolshammer brake did not use a slide , but piston-controlled valves . This has achieved several advantages, such as shorter response times and lower maintenance costs. The control valve was insensitive to pressure losses and worked perfectly even with small release steps.

The Swiss Federal Railways (SBB) were able to convince themselves of the reliable functioning of the Drolshammer brake in everyday life in various practical test missions. In August and September 1927, the SBB therefore presented a test train with control valves of the Drolshammer type to the UIC subcommittee. On November 28, 1928, the SBB's Board of Directors decided to equip 15,000 freight cars with the Drolshammer brake. It was in routine use with the SBB from 1929. Individual copies are still in operation in so-called “planet cars” today (as of 2013).

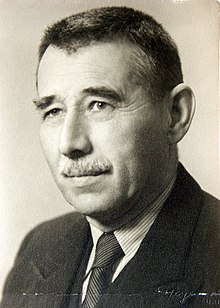

The Drolshammer brake was developed by the Norwegian inventor Ivar Drolshammer (born: 1884 in Drammen , Norway - died: 1954 in Erlenbach ZH , Switzerland).

History and introduction of the Drolshammer brake at SBB

Almost a decade after the end of the First World War , the railways of Europe succeeded in implementing one of the most important technical improvements, which made it possible to increase safety, increase productivity and, at the same time, reduce the workforce: the introduction of the automatic air brake for freight trains. The brake could be used freely on all normal-gauge routes, including on mountain railways with steep gradients such as the Gotthard, Semmering , Arlberg or Mont Cenis . The project required a gradual conversion of the large park of existing freight cars. The investments required for this should be amortized within a decade thanks to the savings achieved in operation.

The technical conditions for the approval of a compressed air brake for freight trains were laid down in Paris by the International Union of Railways (Union Internationale des Chemins de Fer, abbreviated UIC), founded in 1921. The technical commission of this association commissioned a sub-committee made up of leading experts from the most important European railway companies. The chairmanship of this subcommittee was transferred to the SBB. The SBB had been actively pursuing and promoting the development of a compressed air brake for freight trains for years. In 1923 they made the first operational tests with a new type of brake by the Norwegian engineer Ivar Drolshammer. Thanks to intensive cooperation with the inventor, the SBB succeeded in 1927 in demonstrating the practical suitability of the new brake with extensive test drives even under extreme conditions. In 1928 the “Braking” subcommittee of the UIC then applied for the Drolshammer brake to be approved for use in international traffic. The most important milestones in this remarkable development are outlined below.

Development of the compressed air brake

In the second half of the 19th century, there was a real boom in the construction of railways in Europe and the USA , which soon became the backbone of the national transport networks . They were usually built and financed by private companies in an increasingly fierce competition for the necessary sovereign concessions. Railways became the ultimate symbol of technical progress; Locomotives , bridges and tunnels were considered engineering masterpieces. Amazingly, however, a central technical component remained at the level of the stagecoach, so to speak : the locomotive and the wagons were braked by means of a hand-operated block brake . Engine driver and heater operated, the brake of the locomotive, more distributed on the train brakeman`s those of passenger and freight cars. Whistle signals from the engine driver served as commands to apply or release the brakes on the car.

It didn't take long for this rudimentary method to reach its limits. Serious accidents due to insufficient braking effect raised the call for a brake that would affect the entire train but be centrally controlled by the engine driver. Numerous inventors on both sides of the Atlantic have been working on relevant projects. The breakthrough came in 1872, when the American engineer George Westinghouse (1846–1914) presented the “automatic air brake” named after him.

The Westinghouse brake made it possible to operate the brakes of the entire train both from the locomotive and from each car, and it also worked automatically when the train was disconnected due to broken couplings. The function is based on a continuous compressed air line that is fed from the locomotive. The brake is ready for operation as soon as this line - referred to as the main line - is under an overpressure of 5 atm , which is used to fill the auxiliary air reservoirs installed on all trolleys. To initiate braking, the engine driver reduces the pressure in the main line. This pressure reduction activates the so-called control valve on all cars, which transfers air from the auxiliary air reservoir to the brake cylinder . If the pressure in the main line is increased again to release the brake, the control valve changes its position: it reconnects the main line with the auxiliary air reservoir and lets the air out of the brake cylinder to escape. The Westinghouse air brake proved to be very reliable from the start and quickly spread both in the USA and Europe. It had a single weak point: the braking effect could be increased gradually by lowering the main line pressure; as soon as the engine driver increased the main line pressure again, the brake was immediately and completely released on the entire train. The brake is therefore called " single release ". The locomotive driver had to be particularly careful not to initiate another braking process until the pressure in the main line had again reached the setpoint of 5 atm. Otherwise, the braking power was reduced to such an extent that the braking force gradually decreased. This disadvantage did not stick to a competing product of the English engineer John Hardy (1820-1896). Hardy later worked in Austria. Its brake worked with negative pressure and was also graduated when releasing and therefore "multi-release". It was subsequently referred to as the vacuum brake .

Air brakes versus vacuum brakes

The two companies Westinghouse and Hardy fought a bitter struggle for supremacy in the face of the huge market in Europe from 1880 onwards. Reports about real or potential weak points of the respective competitor filled whole shelves. After ten years the question, which at times had led to a kind of religious war among the railway companies, was decided. For technical as well as economic reasons, the compressed air brake prevailed over the vacuum brake, the components of which were simple but much heavier. England and Austria were the only ones to stay with the vacuum brake temporarily.

The five main railways in Switzerland at that time ( Nordostbahn , Vereinigte Schweizerbahnen , Zentralbahn , Jura-Simplon-Bahn and Gotthardbahn) were also involved in this issue . When the Gotthard Railway started operating in 1882, it initially switched to the vacuum brake, but later switched to the compressed air brake.

The unsolved problem of a brake for heavy freight trains

By the end of the 19th century, most passenger and express trains in Europe were equipped with a continuous brake . Freight trains, on the other hand, still operated hand-braked because the technical requirements for a continuous brake are much more difficult to meet here than for passenger trains.

Freight trains are longer and contain both empty and loaded wagons, the braking force of which can be distributed very differently in the train set. The braking has to be relatively gentle at first and should only increase afterwards in order to avoid dangerous strains in the train. For the safe guidance of long freight trains on downhill slopes , a brake that can also be graduated when releasing is indispensable in order to be sure to rule out a gradual decrease in the braking force. The European countries and railway administrations were aware that the economic advantages of a continuous freight train brake could only be achieved if it could be used without restriction in international traffic. This in turn required the conclusion of a corresponding international agreement. In 1909, an "International Commission for Technical Unity in Railways" made up of 17 countries tried to oblige the participating countries to introduce a single, uniform type of brake of this type. The agreement agreed in Bern - known as the "Bern Program" - already formulated a number of technical conditions. However, the approach pursued would inevitably have led to an industrial monopoly situation and therefore had no political chance. The First World War then brought the work to an abrupt end.

The International Union of Railways UIC, which was founded in Paris after the war, was a non-governmental organization of all major railway companies . The association recognized the importance and urgency of the long- standing concern and commissioned a professionally staffed “Braking” sub-committee to take up the necessary work immediately. In 1926, this committee, headed by Max Weiss (1873–1930), who was then head machine engineer for the Swiss Federal Railways, agreed on 33 conditions that a future continuous freight train brake had to meet.

Two of these conditions were particularly important for SBB as the operator of the Gotthard and Simplon lines :

- The reserve of braking force must not decrease even when driving on long and steep slopes. The brake must be designed in such a way that the longest and strongest inclines occurring on main routes can be negotiated with complete safety and the least possible fluctuations in the prescribed speed.

- The freight train brakes to be newly approved for international traffic must work perfectly with freight train brakes that have already been approved .

Test drives with the Drolshammer brake

In 1927, Westinghouse and the German Knorr-Bremse were the first two manufacturers of compressed air brakes to receive approval for freight trains in international traffic. Both companies had technically modified their previous passenger train brakes and thus met the new conditions of the UIC sub-committee. In contrast to this, the control valve developed by Ivar Drolshammer was practically unencumbered by the past: it consistently used more modern piston-controlled valves instead of the previous slides and thus achieved several advantages at the same time, such as shorter reaction times and lower maintenance costs.

The control valve is insensitive to pressure losses and works perfectly even with small release steps. When the engine driver handled the brake, the Drolshammer brake proved to be clearly superior to its competitors on long downhill stretches.

In various practical trials, the Swiss Federal Railways were able to convince themselves of the reliable functioning of the Drolshammer brake in everyday life.

In August and September 1927, the SBB therefore presented a test train with control valves of the Drolshammer type to the UIC sub-committee. The tests included stationary measurements on the stationary train in Biasca station as well as driving tests on the Gotthard south ramp Airolo- Biasca and on the Corbeil - Montereau route in France. For the test train, 82 two-axle freight cars , three observation cars , the so-called dynamometer car and three steam locomotives of the type C5 / 6 were equipped with Drolshammer control valves. Another 20 freight cars without air brakes could be used as "cable cars". The trips took place with an empty train of 198 axles, a partially loaded train of 148 axles and a fully loaded train of 104 axles.

The tests confirmed the perfect functioning of the new brake, which fully met the 33 conditions for international approval defined in the previous year. On the basis of these results, the SBB General Management requested its Board of Directors on November 28, 1928, to equip 15,000 freight wagons with the Drolshammer brake and to grant a loan of 15 million Swiss francs. At the meeting of the Board of Directors in Bellinzona , the great importance of this decision was personally recognized by the then Head of the Federal Post and Railway Department, Federal Councilor Robert Haab .

Equipping the rolling stock with the Drolshammer brake

On April 24, 1929, the Federal Council decreed that the standard-gauge freight wagons of the Swiss railways be equipped with the Drolshammer brake. This regulation extended to the SBB, the private railways and the private goods wagons registered in Switzerland. A detailed program was drawn up to equip the wagons with the necessary equipment, which had to be completed by the end of 1935.

The SBB program envisaged equipping 71% of 14,827 freight wagons, i.e. 66% of the open and 74% of the covered wagons. The renovation program did not include the 2,600 cars to be scrapped during the installation phase and the 1,400 cars to be newly procured. The private railways were asked to convert as many wagons as possible, because due to the large number of foreign wagons without compressed air brakes on the downhill stretches, a lack of specific braking power had to be expected for years.

Only Swiss suppliers were used to procure the necessary brake components. For this purpose, SBB created detailed documents such as drawings, gauges and manufacturing instructions. Particular emphasis was placed on interchangeability because different companies sometimes produced the same component.

The award finally took place on the basis of a submission to a total of 17 suppliers. In the workshops entrusted with the conversion, sample wagons were initially made and then converted to assembly line production for larger series . Thanks to tight management, the demanding renovation program was successfully carried out while adhering to the budget and time frame. The gradual reduction in the number of brakemen required took place without layoffs; the employees who became available were retrained for use in freight and rail services. The economic goals linked to the introduction of the Drolshammer freight train brake were achieved without any problems. The investments made of 15 million francs were amortized within a decade.

After the Second World War , various new control valves appeared in Europe, all of which worked on the principle developed by Drolshammer, but used more modern components. The pistons with their seals were replaced by non-wearing plastic membranes. The SBB subsequently equipped their new wagons with control valves of the Oerlikon type, which were developed and produced by the machine tool factory located there.

The Oerlikon brake replaced the Drolshammer brake mainly because the Drolshammer valve - in contrast to the Oerlikon valve - did not have any additional attachments. It was therefore less flexible to use than the successor model. Because the Drolshammer valve only knows one type of brake and could therefore only be operated as a slow-acting freight train brake . The load braking also had to be regulated outside the control valve - mostly mechanically, by changing the force triangle in the brake linkage.

Ivar Drolshammer (1884–1954)

Ivar Drolshammer was born on January 23, 1884 in Drammen, Norway, to Gudbrand Olsen and Marthe Drolshammer; he was the third of six children. At the age of nineteen he went to the engineering school in Zwickau in Germany. After completing his training, he held various positions in the mining machine industry in Essen and Mülheim an der Ruhr . He then worked for ten years as the technical manager of a machine factory in Isselburg on the Lower Rhine. The focus of his work here was the optimization / development of braking systems on tunnel railways, which had to meet very high demands on the mostly steep access routes to deep-lying stations. His topic was initially hydraulic , later pneumatic brake types. He became increasingly convinced that his ideas could also be applied to railways. Mountain railway routes were a particular challenge for him , especially the braking of heavy freight trains on steep inclines. In the meantime, his inventive ideas fulfilled him so much that he finally dared to take the step into self-employment and devoted himself to deepening it. The result was a continuous automatic air brake for freight trains, the Drolshammer brake .

Drolshammer presented his invention in Switzerland, where, in view of important transit routes in mountainous terrain - especially the north-south axis on the Gotthard, which is important in Europe - interest was to be expected. The Swiss Federal Railways took the risk and decided to test the new design. In 1927, under the control of an international commission of brake experts, extensive test series were started with long trains on the Gotthard and on the plain. The system was convincing; it fully met the requirements of the International Union of Railways and was subsequently certified for traffic. The patents were taken over by the SBB, the production order received among others the company Saurer .

In the course of the above development, the SBB wanted Ivar Drolshammer to move to Switzerland with his wife and two children - so they all moved to Erlenbach ZH, Switzerland in 1928. The last engineering work was completed from here. Ivar Drolshammer died on June 20, 1954 at the age of 71 in Erlenbach ZH, Switzerland.

Individual evidence

- ↑ Wilhelm Hildebrand, The Development of the Automatic Single-Chamber Air Brake on European Main Railways , Springer-Verlag Berlin Heidelberg GmbH, 1927

- ↑ a b Ebert, Experiments with air pressure brakes for freight trains , Organ for Advances in Railways, page 34, volume 84, 2nd issue 1929

- ↑ Gernot Krauss, Dipl.-Ing. (FH), From the far north to the high mountains , AWV Aktuell, magazine for railway workers, page 18, issue 1–2 / 2014

- ↑ a b c d e f g h i j k l m n o p q r s t u v Theo Weiss, retired upper machine engineer at SBB, The Drolshammer automatic air brake - on technology and history , November 15, 2016

- ↑ Experiments with the Drolshammer freight train brake , Schweizerische Bauzeitung, page 329, Vol. 91/92, June 30, 1928

- ↑ International Union of Railways V. Committee, Report of the Subcommittee for the Through Freight Train Brake - Results of the Tests with the Drolshammer Brake , March 1928

- ↑ Drolshammer control valve , regulations on the types and components of compressed air brakes, SBB, reprint of November 1, 1964 for R 450.3 (German edition), R 450.2 (volume II), issue 55

- ↑ a b c Max Weiss, upper machine engineer of the SBB, freight train air pressure brakes , with special consideration of the Drolshammer brake , Schweizerische Bauzeitung, page 5, Vol. 91/92, July 7, 1928

- ↑ Board of Directors of the Swiss Federal Railways, 9th term of office, minutes of the 16th meeting on November 28, 1928, held in Bellinzona, in the town hall, at 10:30 a.m.

- ↑ a b From family documents and conversations with son Ivar Drolshammer junior (1912-2004)

- ^ Nekrolog Ivar Drolshammer , Schweizerische Bauzeitung, page 444, vol. 30, 72nd year, 1954