Wooden beam ceiling

A wooden joist ceiling (also regional beam ceiling or tram beamed ceiling ) of construction machinery is in a basement ceiling with supporting elements made of wood in the form of serrated or sculptured (ceiling) beam , the beam position . The beams lie on the outer walls and the load-bearing inner walls, possibly also on special corbels that protrude from the inside of the wall . Wooden beam ceilings were common in multi-family houses until around 1940, and in single-family houses until around 1960. After that, ceilings in solid houses were mostly made of reinforced concrete .

Layout and function

The spacing of the beams is very different and depends on the expected load, the dimensions of the beams and the structural requirements, such as necessary openings for chimneys and stairs . In residential buildings they typically range from 1.2 m to 50 cm, in younger buildings they are usually shorter.

The upper end (i.e. the accessible area of the wooden ceiling) is usually formed by the plank floor ; these are boards attached across the beams.

A disadvantage of the wooden beam ceilings is their low level of sound insulation , a relatively high amount of work involved in production and their flammability. Problems can also arise with infestation by fungi ( dry rot ) and insects (house buck ), which, however, are generally inherent in wood.

Since the construction tends to vibrate when it is walked on and offers little resistance to heat and sound , a more complex structure is common in residential buildings . To dampen the vibrations of the impact sound , the ceiling must be weighted, which is usually achieved by filling the cavities between the beams. If the filling is made as a fine-grained bed , it can improve the airtightness and the airborne sound insulation at the same time . Sorptive materials also compensate for fluctuations in humidity. Locally occurring bulk materials are used as filling material. The following typically come into question:

- Blast furnace slag ,

- Sand, especially so-called burning sand , which has been heated and is therefore practically germ-free, more rarely also grit or gravel ,

- Clay in a broken shape as bedding, as damp is applied and then hardened passed or mixed with wood chips or mineral lightweight material such as

- Perlite , vermiculite , expanded clay , expanded slate ,

- Cellulose flakes , wood fibers etc.

Some materials are mainly used for weighting purposes only. These can be laid in a bed of clay mortar or given a clay layer to improve fire resistance, moisture balance, airtightness, airborne sound insulation, wood protection and the drying behavior after unplanned moisture penetration of the ceiling construction:

- Plasterboards or molded elements made of plaster

- Fired hollow clay plate ( hourdis ) in hourdis ceiling

- Concrete pavement slabs ,

- Sections or remnants of plasterboard (which can also improve the fire resistance of the ceiling construction) or other building boards.

The insert of special mineral wool mats can increase the airborne sound insulation.

The filling materials lie on a so-called blind or false floor . If the false floor is inserted between the boards, it is also called an insert . Traditionally, the insert consisted of wooden clubs wrapped in straw clay . Today mostly short wooden or slab boards are used, which are also known as inserts .

The form elements and plaster and brick panels can support themselves and thus serve both as an insert and as a weight. Spreading with mortar or a fine-grained fill on top improves sound insulation, airtightness and fire resistance.

Filling ceiling

The space between the bars is called a filling or insert . In the case of the infill or insert ceiling, the undersides of the beams often remain visible and are partially covered with profiles such as B. decorated fillets or carvings . The Cologne ceiling is a special form in which the beams are decorated with stucco ornaments.

Before industrialization , particularly in timber-framed houses , the filling consisted mostly of Lehmwickeln ( Weller wood ), which are thatched clay wrapped wooden sticks ( Punting , which are inserted into grooves of the floor beams). This construction is called the diaper bottom .

- With “whole diaper floors” the layer of clay was smoothed underneath by applying “fat and cohesive” clay and then whitewashed after it had dried out. The space above the loam was mostly partially filled with a layer of sand, slag, building rubble or dry, broken loam.

- In the case of “half diaper bottoms”, the stakes were set higher and the underside was only spread thinly. If a closed layer of plaster was planned under the joists, they were often only covered with clay on top.

- different variants of diaper bottoms

Mainly in the Alpine region and in southern Germany planed boards were inserted between the beams, which are sometimes also color taken or were carved. A more complex application of this technology is the coffered ceiling .

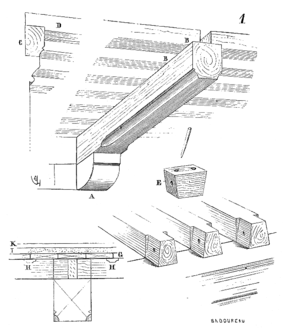

Exposed ceiling beams

Modern wooden joist ceilings are often designed with a sub-floor or board layer , footfall sound insulation and floating screed above the joist layer, so that the underside and side surfaces of the joists or the laminated beams are visible and the result is a strongly structured underside of the ceiling.

Historically, "stretched diaper bottoms" were used when thin rods were available in sufficient quantities . For this purpose, split or roughly hewn poles were placed over the ceiling joists and covered with straw clay and, if necessary, a layer of clay screed.

Closed ceiling

- Wood cladding ( wood paneling ) is attached to the underside of the beams .

- Plastered ceiling:

- Roughly hewn slats with the roughest possible surface or trapezoidal strips, which act as plaster bases (older version), are nailed to the underside of the beams.

- Mats made of reed can be nailed to the spaced battens (trellis battens), which serve as plaster supports (more modern design).

- Suspended suspended ceiling: an additional substructure made of metal profiles or squared timber is created using spring-mounted holders , which in turn carries a cladding made of wood or plasterboard (subsequent acoustic improvement of the ceiling).

Chaff ceiling

In a more massive construction of the wooden beam ceiling, the ceiling consists of beams lying next to one another, which are pegged one below the other (at a distance of approx. 1–2 meters), hence also dowel tree ceiling or Upper German chaff ceiling . The beams are generally ½ – 1 span (10–20 cm) thick and as wide as the trunk allows, often alternately laid in order to save material , and used up to the edge of the forest . This construction is much more resilient and also has excellent thermal insulation values.

The superstructure is made with upholstered wood and floorboards , in between there is often a heavy fill for the purpose of footfall sound insulation . Also screeds are possible, but risky for the wood when there may be barriers to halting humidity. The lower cladding is possible with wood paneling or plastered, applied directly to the joist layer. In the case of perfect wood (and trees of the same size), material visibility was also found in rural surroundings, the joints, for example, slatted (covered with decorative strips) - but unplastered ceilings became rarer in Europe in the 19th century due to stricter fire protection regulations.

Installation of the beam heads

Position security

If the wooden joist ceiling is designed as a disc in order to be able to stiffen the walls of the building, a connection with the masonry is necessary, for example by means of wall anchors , through a firm bond with the wall batten , which is itself anchored in the masonry.

Otherwise, it is often enough to hang up loosely. Securing the position by means of “dry” walling can also be provided. This means that a capillary transition of the masonry moisture to the wood is reduced in that the masonry is only brought up to the side of the beam at as few points as possible and that no mortar is used at the contact point. A perforated brick is often cut in half and placed on the sides of the beam in such a way that the perforation allows a certain amount of moisture to be equalized between the head of the beam and the space between the ceiling.

A blocking intermediate layer could also be used. However, this prevents the beam from drying out if it has a higher level of moisture than the masonry.

Moisture protection

In the past, the roof cladding was often not made as tight as it is today, so that under certain circumstances certain amounts of rainwater could run into the outer wall. In the case of roofs with a snow guard and, due to the reduced pitch of the rafter roofs, in the area of the pegs, the area near the eaves was particularly at risk. The pack of snow that collected here was able to hold back the condensation that ran off in the spring and let it drain through the roof.

Small amounts of penetrating water can often spread through the masonry without being noticed. The long-term increased moisture in the wall enables the growth of wood-decomposing fungi in wooden components that come into contact with the masonry, especially in beam heads and wall battens .

According to DIN 68800-3, hazard class 2 must be assumed in this installation situation, at least in old buildings , which suggests treatment with a wood preservative if it cannot be ensured that the masonry is kept dry over the long term. In addition to pressure impregnation, the local application of relatively harmless boron salts is suitable for this .

To protect against increased masonry moisture, the joist heads should be isolated from the masonry by a capillary-breaking layer on the underside. If a film or roofing felt is used as a barrier layer, it should never be made wider than the head of the beam or even run up to the side of it. Otherwise, a trough can form, which blocks rainwater or condensation under the wood.

The joist heads should not have any side contact with the surrounding masonry or with building materials, which can lead to capillary moisture from the outside of the outer wall to the wood.

In parts 2 and 4 of DIN 68800, an air gap of at least 2 cm on the side and above the beam heads as well as an insulation layer between the air layer and the outer masonry is provided. The insulation layer, which is at least 2 cm thick, is intended to reduce the formation of condensation when warm, moist room air from the room below reaches the ceiling level and rises through the air gap. The risk that masonry moisture from the inside of the house will get to the wall batten is much lower than that as a result of driving rain from outside or in the event of water damage from above.

The free flow of air around the joist heads, as provided for in DIN 68800-4, to dry off any moisture that may have penetrated, can hardly be implemented in most buildings, however, as a closed and airtight lower ceiling is required for various reasons:

- the sound insulation requirements according to DIN 4109 cannot otherwise be met,

- otherwise the required fire resistance class according to DIN 4102 (mostly F 30-B) cannot be achieved,

- The Energy Saving Ordinance (EnEV) and DIN 4108 require an airtight building outer skin for reasons of thermal insulation ,

- the air rising through a leaky ceiling construction can cause undesirable drafts for various reasons,

- If the building does not have a closed insulation layer on the outside of the exterior walls, an insulation layer inserted at the height of the ceiling structure cannot completely exclude the formation of condensation in cold outside temperatures.

As an alternative, it is advisable to surround the beam heads with insulating material. On the underside, waterproof insulation made of foam glass , neoprene or rigid foam can be used, whereby rigid foam can under certain circumstances impair the sound insulation .

Vapor diffusion-open insulation material should be used on the outside and top . If moisture penetration of the outer wall by driving rain can be ruled out (e.g. under the roof overhang, on the (south and) east side facing away from the weather, with a double-shell, insulated or clad facade), natural insulation materials made of wood fibers , cellulose , hemp or similar can be used . Due to their capillarity , they can ensure a quick removal of liquid water in the event of an unplanned entry of moisture.

Layers of air in the wall plane should either be avoided, as they hinder the capillary removal of any condensation that occurs, or be in contact with a larger volume of air (such as that in the space between the ceiling) in order to allow any condensate to dry off.

literature

- Bund Deutscher Zimmermeister (ed.): The wooden beam ceiling. Karlsruhe 1957.

Web links

Individual evidence

- ↑ Wooden ceilings Ö-NORM EN 1991-1-1: 2011 1 , chapter "Classification of ceilings (ceiling structures)"

- ↑ a b F. Triest, Königl. Prussian government council and building director in Berlin, manual for the calculation of building costs for all objects of urban and rural art. On the use of the individual trades and the technical officials, arranged in 18 departments - ninth department, containing the work of the mud and staker, the straw and reed decker, the shingle, splitter and spoon decker, pp. 2 ff; Berlin, published by Duncker and Humblot, 1827; accessed in January 2017

- ↑ a b c d Dr. André Peylo: The beam head - how do you do it correctly? , “Protect & Receive” magazine, September 2007