Beverage can

In addition to bottles , tube packaging and beverage cartons, beverage cans are the most important retail packaging for beverages . They sometimes also serve as drinking vessels . They are mainly used for carbonated beverages such as canned beer and soft drinks (especially cola , other lemonades and energy drinks ) and are opened with a pull tab .

General

Modern beverage cans consist of a one-piece, cylindrical container made of aluminum or tinplate and a folded lid made of aluminum with an oval score line and a riveted metal tab , which, as a "built-in can opener", presses the scored oval into the inside of the can by levering it, creating a spout - or drinking opening generated ( stay-on tab ). The most common can sizes in Europe are 0.33 and 0.5 liters; a whole liter is also less common.

There are also five-liter cans with a tap for beer, which are marketed as party kegs . Party kegs are also available with an integrated carbonator with carbonic acid supply, so that the beer stays fresh for several weeks after being tapped. The carbon dioxide also serves as a propellant for the integrated dispensing system.

Beverage cans must have an internal pressure resistance of 6.2 bar . The inwardly curved base gives you a safety reserve; before the can bursts, the bottom bulges outwards, increasing the volume, reducing the pressure.

Since 2003 there has been a deposit for one-way beverage packaging in Germany, the so-called one - way deposit . It applies to packaging with a capacity of 0.1 to three liters and is 25 cents. The introduction is based on life cycle assessments by the Federal Environment Agency from 1995, 2000 and 2002, on the basis of which the beverage cans and one-way bottles were classified by the Federal Environment Agency as ecologically disadvantageous packaging compared to reusable systems .

properties

The broad application of the beverage can as number three among the packaging variants for beverages is primarily due to the fact that the consumer can use unbreakable beverage packaging with a low weight. For the manufacturers of beverages, in addition to these advantages, the barrier effect of this packaging material is also decisive, since the neutrality to aromas and the light protection effect offer good protection for sensitive products. The pasteurisability of the can also makes it possible to achieve a long shelf life for the beverages in this packaging for export . On the other hand, there are the disadvantages of the packaging, in particular its resealability, which is usually not realized. The hygienic cleanliness when drinking directly from the can or even when pouring is not given, because depending on storage and transport, adhering dirt on the outer surface is touched or overflowed.

Manufacturing process

Production begins with wetting a tinplate or aluminum strip with an ironing agent (lubricant) and cutting out suitable disks from which the body is drawn .

First, a flat bowl is created, which is pushed in the ironing machine over a ram through several, increasingly narrower extraction rings - in the process, the bowl is deformed into an ever longer and thinner-walled can. At the end of the ironing machine, the bottom is shaped by a punch. The blank is then trimmed and washed to remove the ironing agent. Then the can is first painted from the outside and then printed on a rubber blanket in one operation. The rubber blanket already contains the entire motif in all colors, these were transferred to the blanket in previous work steps using the letterpress printing process. After drying, the interior is painted with a spray gun and then dried again.

The interior coating serves as corrosion protection and thus to avoid changes in the taste of the contents. Bisphenol A (BPA), which is potentially harmful to health, is released from the inner coating of the majority of the cans, which subsequently migrates to the contents and contaminates them.

To accommodate the lid, which is smaller in diameter, the can edge is drawn in in several steps using molding tools so that the can is slightly tapered in the upper area. To ensure a secure connection with the lid, the edge of the can still has to be crimped , i.e. bent outwards.

After a separate coating of the bottom and possibly a second interior coating, the beverage cans are ready for the bottling plant, where the lid is crimped onto the filled cans. The flanged edge of the can is folded once and that of the lid twice, so that the connection consists of five metal layers encompassing each other in a form-fitting manner.

The production of a can costs an average of eight cents. Tinplate cans and aluminum cans are about the same price.

Ecological aspects

The beverage can is controversial in terms of its ecological balance . See also the aspects of the life cycle assessment of aluminum.

recycling

The entry into force of the compulsory deposit on beverage cans in Germany in 2003 led to a significantly improved degree of collection and cleaner material flows. While the response rate in 1995 was an estimated 25%, it rose after the introduction of the mandatory deposit in Germany. In 2016 it was 98 out of 100 cans, according to the Metal Packaging Europe association . In 2019, the Society for Packaging Market Research (GVM) determined a recycling rate of 99.3% for aluminum beverage cans and 99.7% for those made of tinplate, taking into account the recovery from residual waste and sorting residues. The number of beverage cans thrown away in the environment - in 1998 their share was more than 13% of objects found or 3.4% "visible surface" and thus clearly ahead of other beverage packaging - fell after the introduction of the deposit requirement. GVM determined a share of 0.03% for 2019, taking into account the collection of pledged items.

The recycling of can scrap saves 90 to 95% of the energy required to produce the metal again with aluminum and around 40% with tinplate. However, the initial production of aluminum is extremely energy-intensive, so that 10% of the remaining energy consumption for aluminum recycling is still almost as much in absolute terms as, for example, 60% for iron recycling. In the case of aluminum recycling, recycling itself generates hazardous waste and since various alloying elements (e.g. magnesium) are not removed during aluminum recycling, the aluminum that is recovered is of inferior quality than the aluminum used in can production ( downcycling ). When recycling tinplate cans, the tin layer is usually lost.

The share of recycled aluminum in the total worldwide use of the metal is currently 22%. With increasing demand, for example due to increased use of beverage cans, this proportion will change little over the next few decades. It is not known exactly how much recycled aluminum or tinplate is in a beverage can. The beverage can manufacturer Bell Packaging named a share of around 50% for beverage cans in 2012.

LCA comparison with other beverage packaging

In a life cycle assessment comparing different beverage packaging based on three case studies from 2010, the IFEU Institute comes to the following conclusion:

- For regional beers, returnable glass containers continue to be the most ecologically beneficial system; regardless of different methodological approaches.

- For beers that are sold nationwide, the result changes depending on the method used, with which the aluminum obtained in the recycling is counted. With a credit of 50%, as assumed by the Federal Environment Agency, the reusable glass bottle does better. There is no clear dividing line for the 100% crediting of 100% required by the commissioning beverage industry for the study .

- When using individual returnable glass bottles as well as national marketing of flopped trend and premium beers (assuming a low number of returnable bottles in circulation) with transport distances of over 400 km, beverage cans can achieve ecological impact profiles that are comparable to returnable beers.

According to a study by Deutsche Umwelthilfe, the IFEU study was based on unrealistic values for transport distances and circulation figures. A study by the Society for Packaging Market Research (GVM) showed, however, that long transport distances of more than 400 km are not unrealistic and affect 17.3% of returnable containers for beer. The GVM calculations are based on representative consumer data from the Gesellschaft für Konsumforschung (GfK). The IFEU institute itself felt compelled to publish a manual due to incorrect interpretations of its study by stakeholders, which is supposed to guarantee the correct interpretation.

According to a press release published by the Federal Environment Agency in 2010, cans still do poorly from an ecological point of view compared to reusable beverage packaging.

According to the environmental organization Greenpeace cause aluminum beverage cans in the preparation of the three-fold CO 2 emissions from returnable bottles made of glass or the six-fold CO 2 emissions of reusable bottles made of plastic, also a half times (mass) occurs at red mud as a waste product.

Beverage cans are thrown away on pastures, the doses are in the mowing shredded by the mowers into small pieces. If cattle then ingest the razor-sharp can pieces with the feed, this can lead to their death.

story

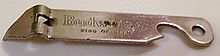

The idea of offering beverages in cans stems from the prohibition era in the United States. After the end of 1933, the Gottfried Krueger Brewing Company was the first to offer canned beer. Standard tin cans were used, which came with an opener with which a triangular opening could be pushed into the lid. After a test phase, Krueger canned beers were also offered nationwide, and by 1935 the brewery was able to increase its sales by over 500 percent. In the same year, the then largest US brewery, Schlitz, developed a bottle-like beverage can with a conical lid and an opening closed by a crown cap , the so-called Cone Top Can .

The beverage can was offered in this form in 1937 by Schmalbach-Lubeca (now Ball Packaging Europe ) in Germany, but initially found little use, as metals were soon given preference to the armaments industry. After the end of the Second World War , Schmalbach-Lubeca resumed production in Germany in 1951, this time with simpler jars made of three parts (base, body and lid) that did without the crown cap. They were initially made from black plate. The first (test) cans of soft drinks were produced in the USA in 1936 and contained Coca-Cola . In Germany, Coca-Cola was first bottled in cans in 1963, followed by Fanta Orange (lemonade with orange juice) and Fanta Lemon (lemonade with citrus extracts) in 1965.

The first aluminum beverage cans came on the market in 1958. With them, the body and base consisted of one piece, which also made it unnecessary to fold open a separate base. They were initially extruded ; From 1966, deep-drawn aluminum cans came onto the market.

In the course of the further development of the beverage can, its weight has been steadily reduced through material and production optimization. While a 0.33 liter beverage can weighed around 100 grams in the 1930s and over 80 grams in the 1950s, a modern aluminum can with a 0.5 liter content now only weighs around 16 grams, which is around half the weight of its tinplate counterpart. A single gram less weight of the can saves around 54,000 tons of metal per year with a total European market volume of around 54 billion pieces. It should be technically possible to manufacture beverage cans with a wall thickness of just 97 micrometers. The world's largest manufacturer of beverage cans is Rexam .

Since 1962 there have been beverage cans with drinking openings that could be opened without tools - a metal strip, called a lift tab , could be torn off the drinking opening by hand. It was replaced by the ring-pull system invented by Ermal Fraze (which he had patented in 1963), in which an oval area of the lid marked by a scratch line with a riveted metal tab, later in the form of a ring, could be torn out. Today's beverage cans usually have the stay-on tab , invented by Dan Cudzik in 1974 , in which this area is not torn out, but pressed into the inside of the can. The Stay-On-Tab was first used by the Falls City Brewing Company from Louisville, Kentucky. In Austria it was particularly widespread from the 1990s onwards. In addition, in the mid-1990s there were beverage cans with an additional drinking opening system: Two small metal “buttons” had to be pressed into the can. First the smaller one, which served as an air inlet, then the larger one as a drinking opening.

In 2007, in a test phase in Germany, a beverage can developed by Ball Packaging Europe with the resealable Ball Resealable End (BRE) lid was offered for the first time. The plastic cap must be turned counterclockwise to open and clockwise to close. This plastic and aluminum lid goes back to a patent application by Antonio Perra. With the energy drink Relentless produced by Coca-Cola , cans with this lid went into series production for the first time in Germany in 2009. The resealable beverage can is the same as the "half-liter can" in terms of its shape, size and stackability, but has a reduced content of only 485 ml it is now also possible to pasteurize beverages, as is necessary, for example, with the fruit-juice- containing Relentless varieties Devotion and Immortus . Since 2013, however, Coca-Cola has not used the resealable lid at Relentless for "corporate strategy reasons".

With thermochromic (temperature-dependent) printing inks, can decors have an infotainment character. The decor changes depending on the temperature. This temperature-dependent interaction is achieved by adding special color pigments to the printing inks. In 2010, the Molson Coors Brewing Company (MCBC) in Great Britain launched the first product filled in thermochromic beverage cans from Ball Packaging Europe.

The self-cooling beverage can has also been invented. Although a small amount of cooling occurs when every pressurized container, including a carbonated beverage can (according to Gay-Lussac's law ) is opened, a special beverage can can also be reduced by 15 to 20 Kelvin using a spiral-shaped gas cartridge that relaxes when opened cooled down so that pre-cooling in the refrigerator is no longer necessary.

Dimensions and packaging

There used to be standard sizes for everyday products. Over time, the pack sizes for more and more products have been deregulated. With the implementation of the EU decision on the complete release of pack sizes, there have only been restrictions for wine, sparkling wine and spirits in Germany and Austria since April 11, 2009. There are the main dimensions 330 and 500 ml, the traditional standard dimensions of 150, 200 and 250 ml for certain product groups (coffee specialties, prosecco, energy drinks) and applications (e.g. aircraft) and the newer, more creative and possibly logistics-supporting dimensions.

The popular 330 and 500 ml beverage cans have a diameter of 67 mm. The height of the 330 ml variant is 115 mm, that of the 500 ml variant 168 mm. The resealable 485 ml beverage cans have the same external dimensions as the 500 ml beverage cans.

For energy drinks in particular , Red Bull has been setting a standard since 1987 with 250 ml. This size is also used for more specialized drinks such as mango juice. They are narrower and taller, 53 mm in diameter and 135 mm in height. Red Bull has been available in the same proportions since 2007 in 355 ml and since 2009 in 473 ml (63 mm × 180 mm).

Since 2006, however, the so-called 330 ml Sleek Can has been increasingly offered in Germany, mainly by Coca-Cola . It is narrower and taller than the classic 330 ml can, has a diameter of 58 mm and a height of 146 mm.

Other sizes common around the world are 150 ml (e.g. in some airliners), 250 ml, 355 ml (equivalent to 12 ounces ; regular size e.g. in the USA ), 440 ml ( e.g. beer in Great Britain and Ireland) and 470 ml (e.g. Guinness ), 340 ml in southern Africa. There are other sizes that are rarely used.

In addition to the above Materials are also used to a very limited extent, polyethylene terephthalate (PET) and coated paperboard, in the manufacture of beverage cans.

Beverage cans are usually available in retail outlets as individual containers and are delivered in open or foil-wrapped cardboard trays in units of 24 or less often 18 pieces. They are often also available in multipacks with different packs of pieces. The best known and most widespread is the so-called six-pack or the six- pack , in which the cans are arranged in two rows of three cans each. There were and are also packs of three (1 × 3 cans), four (2 × 2), eight (2 × 4) and twelve packs (3 × 4). While the multipacks were made of cardboard in the past, foil is increasingly used today for reasons of cost. Multipacks are often offered with a price advantage compared to individual purchases in order to encourage higher sales. In some cases, six-packs are also expanded by two more cans and offered as 6 + 2 free eight-packs. Here the customer pays the price of six cans and the one-way deposit of eight cans.

Number of beverage cans on a Euro pallet using the 330 ml Sleek can as an example:

- Doses per tray: 24

- Trays per layer: 11

- Layers per pallet: 9

- Trays per pallet: 99

- Cans per pallet: 2376

- Dimensions in cm L × W × H: 119.8 × 83.5 × 147.6

Market development

Germany

Before the introduction of the mandatory deposit, the sales figures in Germany were over 8 billion units before 2003. As a result of the mandatory deposit, they fell to well below 1 billion cans. Recently, food retailers have been adding more beverage cans to their product range. At the end of May 2010, Penny-Markt and Netto Marken-Discount announced their return to the can and at the beginning of June 2013 Norma followed after they had only waited for the market to develop. Cans also simplify logistics for discounters: They are lighter, easier to stack and more space-efficient than glass and PET bottles, and they are stable and compact.

In 2011, for the first time since the introduction of the deposit, over a billion cans were sold in Germany. In 2014 sales reached around 1.8 billion. In 2016, sales in Germany increased further to 2.5 billion units.

Switzerland

For the first time in 2013, more than a third of all beer was sold in beverage cans. The brewery association puts the proportion in its statistics at 33.4%. In 2004 it was 16.4%. The increase is at the expense of returnable bottles and draft beer sold in restaurants.

Health aspects

Web links

Footnotes

- ↑ MEBAK , Brewery Analysis Methods , Containers and Equipment, Volume V, Chap. 3.1, p. 1.

- ↑ Life cycle assessment of beverage packaging (Federal Environment Agency) , August 9, 2000.

- ↑ Consumers appreciate the good properties of the beverage can . April 11, 2013. Archived from the original on June 14, 2016. Retrieved June 14, 2016.

- ↑ Susanne Blüml, Sven Fischer, Handbuch der Fülltechnik , Behrs Verlag Hamburg, 2004, pp. 108–113.

- ↑ Questions and answers on bisphenol A in consumer products . Federal Institute for Risk Assessment . May 23, 2013. Retrieved September 17, 2013.

- ↑ Silvia K. Müller: At least 84% of the soft drinks and cola charged in cans with bisphenol A . Chemical Sensitivity Network . March 6, 2009. Retrieved September 17, 2013.

- ↑ Carsten Dierig: The amazing comeback of the beverage can. In: welt.de. May 16, 2017. Retrieved May 17, 2017 .

- ↑ a b Recycling of beverage cans - final report. On behalf of DAVR GmbH, Forum Beverage Dose GbR, ThyssenKrupp Rasselstein GmbH. Society for packaging market research, accessed on August 9, 2021 (presentation).

- ↑ Umweltbundesamt (Ed.): Evaluation of the Packaging Ordinance - Evaluation of the mandatory deposit . April 2010, ISSN 1862-4804 ( umweltbundesamt.de [PDF]). , Table 2-3

- ↑ Europeans increase recycling rate for aluminum cans. In: Recyclingmagazin. August 3, 2011, accessed April 19, 2013 .

- ↑ a b G. Rombach: Raw material supply by aluminum recycling - Efficiency evaluation and long-term availability . In: Acta Materiala . 2013, doi : 10.1016 / j.actamat.2012.08.064 ( html ).

- ↑ a b Norbert Kopytziok: Is aluminum / tinplate recycling worthwhile ? In: Handbook for environmental and waste advice . 19th result. July 2005, 2.11 ( kopytziok.de [PDF]).

- ↑ Patrick Albrecht et al .: Reusable and recycling systems for selected beverage packaging from a sustainability perspective . Ed .: Deutsche Umwelthilfe. June 2011, p. 130 .

- ↑ Horst Wenzel: Cans have around 50 percent recycled content . In: Lebensmittel Zeitung . No. July 29 , 2012.

- ↑ IFEU Heidelberg (publisher): regional beer from returnable bottles is ecologically recommended! - IFEU study on aluminum cans . ( ifeu.de [PDF]).

- ↑ Source: IFEU Institute (PDF; 112 kB)

- ↑ Press release: A lesson in consumer deception: How can manufacturers make beer cans count in an environmentally friendly way. Deutsche Umwelthilfe, August 4, 2010, accessed on April 19, 2013 .

- ↑ GVM (life cycle assessment): PDF

- ↑ ifeu Institute for Energy and Environmental Research Heidelberg GmbH (Ed.): Summary of the handout for the discussion about disposable and reusable beverage packaging . July 13, 2010 ( ifeu.de [PDF; 742 kB ]).

- ↑ Comeback of the can. In: Umweltbundesamt.de

- ^ Greenpeace: Aluminum , website

- ↑ Sacha Buchbinder: Thrown aluminum cans - death sentence for cows , SF Schweizer Fernsehen, June 4, 2012

- ↑ CollectibleSodaCans.com ( Memento August 5, 2003 in the Internet Archive ) Although the idea for canning Coca Cola began in the 1930's, culminating with the creation of a 16oz and a 32 oz cone top can in 1936

- ^ Collection and documentation of the history of German Coca-Cola cans . On: coca-cola-dosen.de

- ↑ Light weight. (No longer available online.) In: Ball - Sustainability. Ball Packaging Europe , formerly in the original ; Retrieved April 7, 2011 . ( Page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ Packaging Europe . Volume 2.2, 2007, p. 21.

- ↑ Patent application US20050150889 : Device for sealing foodstuff containers and foodstuff container provided with such a device. Registered on January 13, 2005 , applicant: A. Perra.

- ↑ The resealable beverage can is here. Die Handelszeitung, March 27, 2008, archived from the original on October 18, 2009 ; Retrieved April 7, 2011 .

- ↑ First resealable can in the world! (No longer available online.) In: Ball - Product Innovations. Ball Packaging Europe, formerly in the original ; Retrieved April 7, 2011 . ( Page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ Enjoy cold thanks to "speaking" packaging. (No longer available online.) In: Ball - press release. Ball Packaging Europe, February 16, 2010, formerly in the original ; Retrieved April 7, 2011 . ( Page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ Cooling included (PDF; 249 kB), Zeitschrift Getränkeindustrie Sachon-Fachzeitschriftenarchiv.

- ↑ Can sizes. (PDF) (No longer available online.) Ball Packaging Europe, archived from the original on October 17, 2007 ; Retrieved February 23, 2009 .

- ↑ PENNY is the first discounter to start again with beverage cans , press portal / Rewe Group

- ↑ Netto Marken-Discount is the first discounter nationwide to sell beverage cans again , press portal / Netto Marken-Discount.

- ↑ NORMA lists DPG beverage cans ( memento from July 17, 2013 in the Internet Archive ), press portal.

- ↑ Beverage can cracks billion mark ( Memento from February 6, 2012 in the Internet Archive ), Neue-Verpackung.de, In: ksta.de from August 4, 2010.

- ↑ Press release from January 26, 2015 ( Memento of the original from February 10, 2015 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , Forum beverage can.

- ↑ Carsten Dierig: Can deposit: Tin packaging is celebrating its comeback. In: welt.de . May 16, 2017. Retrieved October 7, 2018 .

- ↑ Rifle instead of bottle In: schweizamwochenende.ch , April 26, 2014, accessed on March 20, 2018.