Glatzing-Rüstorf power plant

| Glatzing-Rüstorf eGen power plant

|

|

|---|---|

| legal form | registered cooperative |

| founding | November 18, 1920 |

| Seat |

Schwanenstadt Austria |

| management | Peter J. Zehetner |

| Number of employees | 38 |

| sales | around 7.8 million euros |

| Branch | power supply |

| Website | www.kwg.at |

| Status: 2020 | |

The power plant Glatzing-Rüstorf eGen (KWG) is since 1920 active regional power producers, network operators and energy suppliers based in Schwanenstadt ( Upper Austria ). The cooperative operates a total of seven small hydropower plants along the Ager and maintains its own distribution network in 24 municipalities with around 100 transformer stations and a line length of around 500 kilometers.

Companies

In 2019, the cooperative had 1,020 members with a share of EUR 8 each. The chairman and chairman of the five-person board is Wolfgang Stadlmayr, and the vice chairman is Karl-Heinz Mair. The chairman of the 8-person supervisory board is Walter Pühretmayr, his deputy is Michael Stiefmüller. Peter J. Zehetner has been the managing director of the cooperative since 2016.

KWG operates a total of seven hydropower plants along the Ager and maintains its own power grid at medium and low voltage levels with 121 transformer stations and a line length of 518 km on a total area of 125 km². The electricity labeling (as of 2019) according to Section 78 Paragraphs 1 and 2 ElWOG 2010 and the 2011 Electricity Labeling Ordinance, Federal Law Gazette No. 310/2011, on the proportion of various primary energy sources is divided into 90.0% hydropower, 8.6% wind energy and 1.4 % Solar energy.

In the electricity provider check carried out by WWF and Global 2000, KWG achieved third place in Austria in 2017-2020. It was the leading company in the “solid green electricity supplier” category.

The company is also a member of Österreichs Energie , the Vereinigung Österreichischer Elektrizitätswerke, the Kleinwasserkraft Österreich, the Raiffeisenverband Oberösterreich, the ElektroMobilityClub Austria, the Energieforen Leipzig, the purchasing cooperative of Austrian electricity companies, the Energiesparverband OÖ and the Cleantech-Cluster.

The following municipalities belong (at least in part) to the KWG power grid area :

- Aichkirchen

- Atzbach

- Bachmanning

- Edt at Lambach

- Lambach

- Manning

- Neukirchen near Lambach

- Niederthalheim

- Oberndorf near Schwanenstadt

- Offenhausen

- Ottnang am Hausruck

- Pennewang

- Pilsbach

- Pitzenberg

- Pühret

- Redlham

- Riistorf

- Rutzenham

- Schlatt

- Schwanenstadt

- Stadl-Paura

- Inaccurate

- Vöcklabruck

- Wolfsegg am Hausruck

history

History and establishment of the cooperative

The Ager , the outflow from the Attersee , with the tributaries Vöckla and Aurach and the extensive precipitation area as far as the Hausruck, is Aryan waters, navigable for a long time and serves as a driving force for numerous power plants. Until the end of the 19th century, it was left to its own devices in the intermediate sections of the individual systems. Their care was mainly limited to maintaining the raft trip.

The public sector, with the partial participation of interested parties, then led to the construction of local bank protection structures, until an overall regulatory plan was finally drawn up and implemented. While the regulation work was being carried out, the riverbed deepened considerably in the expanded stretches. Increased bed load resulted, which led to river bed elevations in the open stretches. The area at the mouth of the Kaufinger Mühlbach near Glatzing was most affected by these conditions. The backwater that arose there caused the adjacent grounds to become swampy and the risk of flooding increased. To counteract this development and to establish effective flood protection, the idea of a canal in the form of a dam came up. This could then also be used as a basis for the emerging electrification in the form of a hydropower plant.

The idea was born in the population and should be realized together with them in a cooperative spirit. With the first discussions with the landowners affected by the canal, the advertising work for the establishment of a cooperative could begin. One of the first advertising meetings took place in Hof (Neukirchen).

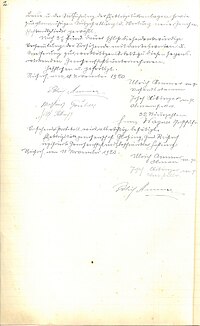

The cooperative effectiveness was known almost exclusively from the dairy industry at that time. They wanted to make use of the experience in this sector and were able to win over the proven and successful chairman, Mr. Wagner, who was also a member of the state parliament and was thoroughly informed about the local conditions. He arranged for the chief inspector of the cooperative, Mr. Hochegger, to come to Schwanenstadt to take care of the establishment formalities, to arrange for the district court registration, to notify the two construction companies Siemens-Schuckert and Schratz and, among other things, to find a reliable clerk in the cooperative system. The cooperative was officially founded on November 18, 1920 with Ulrich Ammer, the first chairman of the economics council. The founding meeting consisted of 32 participants. On June 12, 1921, the cooperative had 70 members; at the end of the year, 380 members were already registered.

After just a few days, the representative from Siemens-Schuckert came to the on-site inspection and stated that the company was ready to carry out all measurements and plans for both the technical and hydraulic systems free of charge if it was guaranteed the delivery of the generators and transformers. The offer was accepted after a brief discussion.

Beginning of the first work

The surveying work began with the requirement to lower the water level that existed at that time in Burgstall. The highest known high water level of the Ager at that time was the flood in 1899, after which the flood protection wall at the main lock was fixed. The height of the dam crowns, especially the client side, was thus finally determined. In the first section, where the terrain was almost flat, the canal was laid in a dead straight line, while in the further course it took advantage of existing terrain hollows in order to reduce the necessary earth movement and to protect the more bearable grounds as much as possible. This ensured that the basic replacement could be carried out by mutual agreement with only two exceptions, with the same efficiency. The redemption of the building plot for the plant brought a considerable additional burden. The building site was relocated to a meadow plot that belonged to an owner in Mitterbergholz and which came close to an old river basin of the Ager. The husband of this owner made the following conditions for the transfer: Not only the required size but the whole lot had to be taken over. The only possible compensation is a basic allocation, and as much as possible, in the vicinity of his home. Fulfilling the latter condition in particular was rather hopeless there. Nobody was willing to give up even smaller areas of land until they learned from the monastery conductor P. Notka von Lambach that the monastery was ready to give back forests that had previously been bought in by way of the repurchase right for compensation. This option was used.

Even with the basic detachment in the lower canal, there was initially a deviation from the other norm. The owner of what was then the largest basic size of the village of Eglau stated that he only wanted an assurance from the cooperative that they would install five lamps for him free of charge and supply them with electricity free of charge for ten years. Reason can then be claimed as much as one needs. Since there was a lot of excavation material to be expected in this section, the offer turned out to be favorable for the cooperative and was therefore accepted without restriction.

In the further course, the route led over the so-called Forstnerlache, a remnant of an old Ager river bed, which had almost the same dimensions as the canal and therefore required little excavation, so that some of the material had to be added for the necessary dam. Although flood protection was created here for nearby reasons, these owners could not decide to join the cooperative. The actual discharge of the canal into the Ager was initially only determined provisionally, as the intention was to keep a free hand for later corrections. With the completion of the plans, the project was ready for commission. Twelve seconds / m³ of process water were planned with a six meter gradient. The interior of the power plant should consist of two turbines for six sec./m³ each, two generators with 380 kVA each, including exciters, switchgear equipment and a station transformer. In addition, a caretaker's apartment, a workshop and an office room were built in the machine house, while the oil magazine and welding shop were housed in an annex. The somewhat isolated operations manager's house contained apartments for three families. The company was designed without a weir system and was run without one for ten years. However, so-called storage compartments were provided in order to feed the necessary service water to the inlet when the water level was low. A so-called tail unit in wood construction was also planned in the project, but was not implemented due to the expansion of the Ager river bed.

During the order picking, the approval for the start of the preparatory work could be obtained, so the clearing of the ground at the inlet was started immediately.

The pull-out room at neighbor Adam could be used as the first provisional office space. This had the advantage of being close to the building site and being close to each other, but it made it more difficult for members to come. That is why an adjoining room in Wagner's inn in Schwanenstadt was set up and used as a law firm. The increase in membership was satisfactory; there were three possible ways of acquiring business shares: 1. through cash payments, 2. through work and 3. through the provision of property or other material assets. At times, the construction progress exceeded expectations. Especially due to a piecework system adopted by the workers, according to which certain sections of the canal were taken over by cubic meters at a fixed price. There were quite a few record performances, as it was not uncommon for the disc chests to roll at five in the morning. Under these circumstances, the intention was to postpone the construction company as far as possible for reasons of economy.

The canal work had progressed so far that the excavation of the foundations for the inlet sluice, a sand sluice planned in the upper canal and the construction pit for the plant could be started and longer taxiway tracks with several tipping cars were necessary.

The circle of members began to emerge on a large scale, it became obvious that the future cooperative area is vast and relatively sparsely populated, as the larger places, easily accessible by the Traunfall management, were already supplied by Stern & Hafferl AG. Every second Sunday there was a meeting in Schwanenstadt, mutual discussions, regulation of the robot performance, later the wagon division, material provision for the transformers, etc. This facility has worked very well and the keen interest confirmed its usefulness.

Flood

Probably the toughest test and the most sensitive setback was the catastrophic flooding that occurred unexpectedly during construction. The possible effects of a flood were discussed earlier, with particular attention being drawn to the danger of a break-in at the sand sluice, as the outer formwork posts protruded a few meters above the profile. The number of employees had already been reduced significantly before the actual bad weather period. The upper canal was already completed and there was not enough prospect of better weather for concrete work, so work was only carried out in the lower canal. After heavy snowfall, which then turned into rain, a thaw set in with a strong westerly wind. The engineer had not been there for a few days because he was later found to be slightly ill. The greatest and most lasting damage was caused by this flood at the factory. The immediate proximity of the excavation and the existing gradient favored the strong water inflow, which very quickly led to the enormous deepening of the break-in point. The water masses flowing in the canal, which surely amounted to twice the amount of the subsequent service water, crashed into the construction pit with a great roar. The bilateral water inflow caused a massive vortex movement in this area, which resulted in major collapses on the right bank. In a hastily held functionaries' meeting, a thorough status report was made and, in order to clarify the critical situation, an application was made to entrust a representative of a company that was previously uninvolved with the new start of the project. The application was unanimously approved, so that after the water had sunk, the new measurement could be carried out without delay.

Half of the Viennese electricity price was assumed as the basis for calculating the price of the restoration or project continuation. After this, it turned out that the expansion of the original project, due to the increased construction costs and the increased interest payments, cannot be expected to pay off in full in the foreseeable future. On the other hand, it was possible to meet all requirements by taking in more process water from the Ager. In consideration of the already considerable investments that had been made up to then, it was decided to continue building.

Now long-term planning had to be done again. The members were put off to a later delivery and informed about the increased construction costs due to the enlargement of the plant. At this point in time, the workplace was more like a neglected gravel pit than a construction site, all the more so since the last inner cladding panels and some pieces of sole in the upper canal were washed away and collapsed. The fact that ridicule was not lacking in such a situation was shown by the fact that a man in a district, which was also quite well staffed with members, had swung up as burial commissioner and buried the Glatzinger work according to custom.

The new project

Of course, new plans had to be submitted and commissioned for this. They contained the following changes: The second turbine had a water volume of 14 m³ / sec. Performance against six cubic meters was previously provided, while the gradient was reduced from six meters to five meters; This is because the sixth meter in the sub-channel contained a material that was particularly difficult to process. According to experts, it was a budding conglomerate. The first aggregate remained unchanged except for the reduction of the slope from six to five meters. The generator for this was already delivered.

The second commissioning dealt with the modification of the project with regard to water drainage and slope, there were no objections. The construction company brought in a new foreman. He was not an engineer, but an experienced practitioner for such buildings, very concerned about solid construction and striving to achieve a corresponding construction progress. He hardly ever got away from the actual work place, even for a short time, since the other work was done by his own people. It was gratifying and encouraging that the upper canal had withstood the test of strength during the flood very well, that its inner walls in the intermediate sections of the break-in points and the short termination point were not affected at all, so that it was expected to carry the increased amount of process water for a long time without worrying about it could. Another preliminary success was the one hundred percent success of the accompanying flood protection for the reasons mentioned earlier, including four farmsteads.

The deeper the excavation became, the more pressurized water rose. When the pumps stopped to remove this water, the pit was full again in a few moments and it was half an hour before work could be resumed. That is why night shifts were put in place to avoid any interruption as much as possible. Some carts were constantly on the move to add fuel. In the first general assembly after the flood it became clear that one group was completely discouraged and no longer willing to remain loyal to the cooperative. Management and supervisory board meetings were held at short intervals and, in one of the same, 59 members who had registered to join but had made no or only inadequate payments or had otherwise committed themselves were excluded from the cooperative.

In this session the constant water flow was emphasized. Furthermore, that “a flood will no longer do any damage once it has been completely expanded. Completion will still require sacrifice, but through some collaboration it can be achieved. The members should also bear in mind that more could have been achieved up to now with full commitment. They should be glad that they have such a favorable opportunity, which has never been presented in the past and will hardly be offered in the future, to become an electricity producer and not an electricity purchaser with any large company. Profitability will arise with the current modern development, since there is a hunger for strength on all sides. "

The financial situation was extremely tense. It would have been an achievement if the members at the time generated their electricity needs themselves and paid for the necessary facilities from their own. The most careful calculations showed that their electricity consumption will hardly amount to one eighth of total production; there were practically no payers for the remaining seven eighths. With a reduced number of members there was now a higher effort and severely shaken trust. Under these circumstances, recruiting for members was hopeless, and no attempt was made at all. However, cash was urgently needed in order not to have to restrict the construction work too far. The most obvious thing to do was to raise contributions from productive unemployment benefits. The further achievement of loans from the federal and state governments and their financial institutions has also been successfully pursued and has thus become decisive for the progress of construction and its completion.

For future electricity utilization, the first interested parties outside of the cooperative registered for electricity from the new plant. E.g .: the incandescent lamp factory in Lambach and the electricity works in Wels. These negotiations quickly got under way and there were no contracts for the purchase of electricity.

So everything still had to be done to achieve adequate electricity utilization. The first step was to get in touch with several electricity cooperatives. The existing conditions were made clear to them and the decision was made to hold out to the utmost. The establishment of the Association of Upper Austrian Electricity Cooperatives had a positive influence on the talks.

After four years of construction, turbine 1 at the Hart power plant was put into operation in October 1924. In total, approx. 9,000 m³ of earth can be moved without construction machinery.

During this time, the state government also sent us a purchase offer from ÖKA. According to this, free electricity was provided for the members for a period of twenty years, at an annual rate of 160,000 kW, 14 annual installments of a 25,000 Schilling and corresponding to the electricity contract obligations entered into by the cooperative. A general meeting resolution was passed on this limited offer. The first vote resulted in only seven votes in favor of the sale, the second vote in favor of the renovation of the plant and the continued existence of the cooperative brought 14 dissenting votes from 130 people present. The guideline was thus decided for the near future.

The "inauguration" and first years of operation

A joint meeting of officials was held in preparation for the ceremonial inauguration of the plant. The day of the inauguration was set for June 29, 1925. The “Linzer Volksblatt” wrote about the consecration itself: “Despite the unfavorable weather, the consecration of the Glatzing electricity works went on in the most beautiful manner.” At 1 p.m., gunfire announced that the festival guests were approaching. These were from the Neukirchen bei Lambach band welcomed.

In the first years of operation, rafting was carried out on a smaller scale. Apart from occasional damage to the above-mentioned retreats, there were no other disadvantages until the first weir was installed. When it was picked, a new regulation was laid down for the raft trip. This is because the raft lane was provided with a bar lock, which had to be removed in order to be usable. This resulted in a temporary loss of operation because the rafts still needed flood water to reach the canal outlet. For this purpose, the so-called small channel was created in the regulation profile in order to manage with less water. "

Source: KWG

Further history of the company

On December 18, 1927, the cooperative received a concession decree. The construction of a new wooden weir in the Ager began in 1934. The line construction was carried out in 1944 by the technical emergency service or the pantograph robot. In 1947 construction began on a concrete weir, as well as the first purchase of external electricity. In 1952 the administration building was built in Staig. In 1956 a garage and material warehouse was built. In 1959 two caloric power generation plants were purchased and a fuel store was built for the Hart power station. In 1976 the hydropower plant was expanded by installing a Kaplan turbine, which enabled the generation of electricity from hydropower to be doubled. In 1982 another warehouse and garage building was built, and an in-house IT system was purchased. In 1984 the still partially caloric generation was expanded to include two powerful diesel generators, a new electrical plant control center was built, and a new power plant and network control center was built in the Hart power plant. 1987 saw the commissioning of the second hydropower plant in Deutenham, purchase of a sawmill area in Staig, purchase of the fishing water in the Ager (7.5 km), acquisition of the Wankham mill including the hydropower plant. In 1992 the E-Werk control room was expanded with the installation of a double computer system and expansion of the control center. In 1993 the Mühlwang hydropower plant was acquired. In 1996, the fully automated networking of all power plants and network operations began. In 1997 the administration building in Staig was modernized. In 2001 the Kaufing hydropower plant was acquired. A flood of the century caused great damage in 2002. The Ager brought out below Deutenham, destroyed, among other things, the underground cable from the power station and flooded the village of Au. At the Hart power plant, hydropower generation was optimized in 2005 by replacing turbine II, built in 1924 with an output of 600 kW, for a bulb Kaplan turbine with an output of 1,600 kW. On January 27, 2008, hurricane Paula and on March 1st, hurricane Emma caused considerable pipe damage, even concrete masts were buckled. The Friesam Industry transformer station was connected to the Timelkam substation in order to increase security of supply. In July 2010, the weir system of the Hart power plant was adapted to the new water framework directive: As part of the general renovation of the old weir system of the diversion power plant on the Ager, the inlet situation was hydraulically improved. In addition, there is a hydropower screw with a water volume of 3.2 m³ / s for energetic use of the residual water supply. The fish migration aid is a pilot system for the MABA Enature fish pass, which has now been established and which already meets the strict requirements of the NGP. The total costs for the measures are calculated at around 1.7 million euros (the under-generation at the Hart power plant of around 900,000 kWh / year, due to the increase in the amount allocated to the Ager, is not yet taken into account). The construction work should be completed by summer 2011, but the floods in 2011 caused damage that delayed the final completion. Commissioning took place in early 2012.

The administration building in Staig was completely renovated in 2012 after 60 years. The roof structure including the covering will be renewed, the building envelope will be thermally brought up to the state of the art and the attic will be expanded into the attic so that it can be used commercially. After six months of construction and adaptation work, the building was taken over in November with a new look and improved usage options. On February 16, 2016, the last 43 m of a bare four-wire line in Oberndorf was replaced by an insulated overhead line. This means that there are no longer any weather-prone lines in the entire low-voltage network.

Source: KWG

Power plants

Hard

| Annual work | 15 million kWh |

| Power plant type | Run-of-river power plant |

| flow | Ager |

| Installation | 1924 |

| expansion | 1976/2005 |

| Turbine type | 1 Francis turbine, 2 Kaplan turbines |

| Expansion water volume | 42 m³ / sec. |

| Dismantling height | 7 m |

| Nominal power (total) | 2.9 MW |

| location | Location |

The existing water continuum at the Hart location is interrupted by the weir system that has been in operation since 1924. In July 2010 the groundbreaking ceremony took place for the adaptation of the weir system to the EU Water Framework Directive 2000/60 / EC. A further step was taken due to the requirements of the Renewable Energy Directive 2009/28 / EC with the installation of a residual water turbine to use the increased endowment of the Ager. The saving of 30 to 40 percent water flow, the main advantage of the enature FISHPASS for the power plant operator, is converted directly into energy by the residual water turbine.

Key data of the fish pass:

| Lead fish, size-determining | Huchen, body length 100 cm |

| Endowment amount | approx. 360 l / s |

| Compared to Vertical Slot | 550 l / s |

| Water savings in% | approx. 35% |

| Basin dimensions L × W × H | 300 × 217.50 × 160 |

| Slot width | 35 cm |

| Height at low water (doping water) | 2.75 m |

| i.e. per slot | 15 cm |

| Number of pools | 18 pools, 1 relaxation pool |

| Dissipation | Emax = 80 W / m³ |

Photovoltaic system at the Hart hydropower plant.

In June 2019, a 120 kWp photovoltaic system was installed on the roof of the Hart hydropower plant.

| Annual work | 120,000 kWh |

| Power plant type | Solar power plant |

| Installation | 2019 |

| Module type | Kyoto module |

| Number of modules | 438 |

| Inverter | 7 inverters, power up to 27 kVA |

| rated capacity | 120 kWp |

Deutham

The power plant was built by KWG itself.

| Annual work | 16 million kWh |

| Power plant type | Run-of-river power plant |

| flow | Ager |

| Installation | 1987 |

| expansion | 1986/2001 |

| Turbine type | 2 Kaplan bulb turbines |

| Expansion water volume | 35 m³ / sec. |

| Dismantling height | 9 m |

| Nominal power (total) | 2.5 MW |

| location |

Wankham I

Originally a water wheel to drive a millstone and a sawmill, it was converted into a power station.

| Annual work | 0.2 million kWh |

| Power plant type | Run-of-river power plant |

| flow | Ager |

| Installation | 1923 |

| expansion | 1952/1994 |

| Turbine type | 1 Francis turbine |

| Expansion water volume | 2.5 m³ / sec. |

| Dismantling height | 2 m |

| Nominal power (total) | 30 kW |

| location |

Wankham II

A power station that has been restored as a power station.

| Annual work | 0.4 million kWh |

| Power plant type | Run-of-river power plant |

| flow | Ager |

| Installation | 1928 |

| expansion | 1994 |

| Turbine type | 1 Francis turbine |

| Expansion water volume | 3.5 m³ / sec. |

| Dismantling height | 2 m |

| Nominal power (total) | 50 kW |

| location |

Mühlwang

The power plant is located on a diversion from the Ager (Buchleiten weir) and was bought in 1993 and integrated into the KWG network.

| Annual work | 2 million kWh |

| Power plant type | Run-of-river power plant |

| flow | Ager |

| Installation | 1956 |

| expansion | 1976/2001 |

| Turbine type | 1 Francis turbine, 1 Kaplan turbine |

| Expansion water volume | 14 m³ / sec. |

| Dismantling height | 2.2 m |

| Nominal power (total) | 300 kW |

| location |

Kaufing

The power plant is located on a diversion from the Ager (Buchleiten weir) and was bought in 2001 and integrated into the KWG network.

| Annual work | 5 million kWh |

| Power plant type | Run-of-river power plant |

| flow | Ager |

| Installation | 1954 |

| expansion | 1976 |

| Turbine type | 3 Francis shaft turbines |

| Expansion water volume | 14 m³ / sec. |

| Dismantling height | 6.5 m |

| Nominal power (total) | 650 kW |

| location |

Timelkam

The Timelkam hydropower plant was acquired in 2017.

| Annual work | 3.1 million kWh |

| Power plant type | Run-of-river power plant |

| flow | Ager |

| Installation | 2016 |

| Turbine type | 1 Kaplan turbine |

| Expansion water volume | 23 m³ / sec. |

| Dismantling height | 3.1 m |

| Nominal power (total) | 585 kW |

| location |

Source: Glatzing Rüstorf power plant

Web links

Individual evidence

- ↑ List of network operators

- ↑ Article Kraftwerk Glatzing Rüstorf - new managing director

- ↑ KWG electricity labeling

- ^ Electricity provider check by WWF and Global 2000

- ^ Members of Austria's Energy

- ↑ member companies . In: VOEEW.AT . ( voeew.at [accessed on July 4, 2018]).

- ^ Members of small hydropower Austria

- ^ Members of the Upper Austria Raiffeisen Association

- ↑ ElektroMobilityClub Austria

- ↑ Forum partner network. Retrieved July 4, 2018 .

- ^ Cleantech cluster

-

^

Kraftwerk Glatzing Rüstorf: Memories of the founding of the Glatzing Electricity Cooperative and the construction of the power station , 1959, pp. 5–37.

Glatzing Rüstorf power plant: 30 years of Glatzing-Rüstorf power plant , 1950, p. - ↑ Projects Warnecke Consult ( Memento of the original from March 22, 2017 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

-

^ Kraftwerk Glatzing Rüstorf: Festschrift KWG 1920-1980 , p. 19

Kraftwerk Glatzing Rüstorf: Festschrift 75 years KWG , pp. 2–3. - ↑ enature projects FISHPASS

- ↑ KWG power plants