New Austrian tunneling method

The New Austrian Tunneling Method ( NED ) is a method of tunnel construction , the main criterion of which is that the part of the mountain surrounding the cavity is used to carry it and thus becomes a component itself . It was developed in the 1950s as a new type of expansion concept at the time and combines geological and rock-mechanical principles with special construction methods to secure and expand a tunnel cavity. These technical advantages also led to lower construction costs, so that the method quickly established itself and has been continuously developed since then.

The New Austrian Tunneling Method (NATM) designation is common in English-speaking countries . In the German-speaking world, the term shotcrete construction has become common in connection with tunnel construction in recent years . In common parlance, the coupling of the shotcrete construction method according to NET is often to be found as a distinction to the use of shotcrete for surface protection.

In contrast to continuous driving with tunnel boring machines (possibly in shield driving ), the NET is a cyclical driving method. A work cycle comprises the following steps:

- " Excavation " (with hammer, excavator, milling drive or drilling and blasting),

- "Securing" (primarily shotcrete, if necessary additional measures such as anchors or umbrella vaults),

- "Shaking" (promoting the outbreak, usually in a dry state).

Securing with shotcrete can also be used for other driving methods (blasting, driving with a tunnel boring machine or shield driving machine). Securing by means of segments can be omitted with the NAT.

history

The need for tunnel construction increased enormously with the onset of railroad construction in the first half of the 19th century. The tunneling methods with expansion and loosening techniques were largely adopted from mining, which, however, placed significantly lower demands on the durability of the structures.

The uncovered tunnel walls were stabilized until the middle of the 20th century, mostly with the help of wooden fixtures, which took up a considerable part of the newly created cavity, so that the final expansion work with masonry made of hewn or uncut natural stone, occasionally also made of bricks, made it considerably more difficult were.

The frequent repositioning of the supports required for this, together with their flexibility and the inadequate surface contact, led to movements in the surrounding rock and, in many cases, to a disintegration of the mountain structure near the cavity. This caused structural loosening, the surrounding mountains were thereby "softened" and burdened the final expansion with its additional weight.

An engineering approach to tunneling and underground construction began with the first major standard textbook on the entire art of tunneling by Franz Rziha in 1867 and 1874. Even then, he stated fundamentally and pointing the way:

"The art of the engineer is to keep high mountain pressure away, that is, not to let arise, a far greater art than that of overcoming the mountain pressure that is once there."

Ernst Wiesmann published further fundamental findings in 1909 and 1912. He was the first to recognize the stress redistribution around the newly created tunnel cavity and drew the following conclusion:

"The tunnel builder does not even have the task of supporting the cavity against overburden pressure; this is what the protective cover does, but only has to be concerned about its preservation."

In 1944, Ladislaus von Rabcewicz put together his own experiences as well as the findings of other experts from the past decades, which had contributed to a better understanding of the geomechanical processes in tunnel construction. He summarized the findings for two core areas of tunnel construction as follows:

For loosening pressure :

"The cause of the loosening pressure lies primarily in the deficiencies of our mining and the temporary expansion used here, which favors subsidence and the formation of cavities."

He pointed out the decisive influence of the time between the creation of the tunnel cavity and the final expansion:

"One of the most important factors for generating the loosening pressure [...] is time. The faster a cavity is closed, the lower the subsidence [...] In the case of loosening pressure, the most suitable tunnel construction and operating method is always to be described as the most suitable one which closes the cross-section, which opens quickly and with the least subsidence, as quickly as possible through an incompressible, final installation. "

On the real mountain pressure he found:

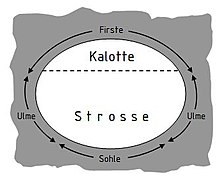

“The primary thing with vertical overlay pressure is a compression of the elms with elastic deflection against the cavity. If the rock strength is not exceeded, nothing happens, the tunnel does not need any brickwork [...] But at the moment when it comes to destruction, the stress pattern changes. In the case of the elms, the tension drops to zero and the increase in pressure shifts further into the mountain. "

A change in the practical tunnel construction started around 1947 with anchors that are built into the surrounding mountains to secure the final tunnel extensions. This process, known as “roof bolting” or “anchoring”, was first used in the USA and Sweden, and later also in Central Europe.

At the same time, shotcrete was increasingly used, which had developed from "Gunit", a shotcrete mortar for renovations, and which was further developed for use in tunneling by the Austrian tunneling engineer Anton Brunner. The theoretical foundations for the then new field of rock mechanics were compiled and systematized together with geomechanical knowledge in Austria by the so-called “Salzburg Circle” around Leopold Müller and Franz Pacher . From 1956 to 1958, Rabcewicz first used the use of system anchors and shotcrete as the sole proppant in the construction of motorway and rail tunnels in Venezuela.

The breakthrough of the New Austrian Tunneling Method in Europe came in 1963 when it was used as a renovation measure after a demolition at the Massenberg Tunnel . As a consultant, Rabcewicz fundamentally changed the construction method, using shotcrete, Perfo anchoring and a relatively quick ring closure. The stabilization process was observed by systematic measurements, whereby the effect of the bottom closure was clearly shown. The construction of the tunnel was then completed without any problems.

Principles and definition

background

With traditional tunnel construction methods, the basic idea behind the creation of the tunnel cavity was to safely absorb the rock pressure , which was regarded as unavoidable, by means of constructive methods such as bracing and extensions. These methods, such as the German core construction method and the old Austrian tunnel construction method, were common until the middle of the last century.

In contrast, with the New Austrian Tunneling Method, the focus is on not allowing these rock pressures at all or only to a small extent and largely preserving the rock's own load-bearing capacity. For this purpose, the local geological and rock-mechanical conditions are taken into account, which means that this procedure goes beyond a pure construction method with schematized procedures for excavating and securing the tunnel cavity.

This fundamental rethinking was made possible by the interaction of theoretical considerations and practical knowledge: When creating the tunnel cavities, Ladislaus von Rabcewicz first recognized the importance of the time influence between the excavation of the cavity and its subsequent securing. In 1964 , Franz Pacher provided explanations of rock mechanics as an interplay between rock pressure and expansion resistance . The engineering geologist Leopold Müller and the Salzburger Kreis were also involved . On the practical side, the securing of cavities was simplified by the variable application of sprayed concrete, the application of which was significantly expanded and improved over the period. Other variable support and extension elements were added, such as spikes, tubular umbrellas, anchors and extension arches. Furthermore, inner linings made of in-situ concrete were added, which connect to the shotcrete layer and are produced using formwork wagons (for example in the Gotthard Base Tunnel ).

Principles

The principles of the New Austrian Tunneling Method were drafted in 1979 together with a definition by the “Tunneling” working group of the Research Society for Roads in the Austrian Association of Engineers and Architects .

| Principles of the New Austrian Tunneling Method (NÖT) in excerpts |

|

|---|---|

| 1 | The main structural component of a tunnel is the mountain |

| 2 | Original rock strength preserved |

| 6th | Don't block too early or too late, not too rigid, not too weak |

| 9 | Securing force-fit (therefore shotcrete) |

| 10 | Installation and expansion thin-skinned |

| 11 | Reinforcements not by thickening, but by reinforcement nets, tunnel arches, anchors |

| 12 | Disposition of building materials and construction times based on measurements |

| 13 | Statically, the tunnel is a pipe consisting of a rock support ring and shoring |

| 18th | Cross-sectional shapes that are as rounded as possible |

| 19th | The inner shell is also slim. Frictional connection with the outer shell. But not by friction. |

definition

The NET follows a concept that turns the mountains surrounding the cavity (rock or soil) into a load-bearing component by activating a mountain ring. A few principles must be observed, such as:

- Consideration of geomechanical rock behavior,

- Avoidance of unfavorable stress and deformation states through the timely installation of suitable support measures,

- in particular, a statically effective base closure that is introduced in good time, which gives the rock support ring the static function of a closed tube,

- Optimization of the expansion resistance depending on the permissible deformations and

- Metrological monitoring also to control the optimization.

For this purpose, 22 principles have been developed both in text form and - particularly clearly - with characteristic sketches and concise abstracts (see adjacent table).

Work steps

The essential work steps in the New Austrian Tunneling Method are excavation and securing with the following details:

outbreak

The following are used to break out:

- Loose rock

- Excavators with bucket , gripping teeth or hydraulic chisels

- Medium rock strength and fissured rock

- Part or full headers with rotating cutting rollers that mill off the rock material with attached chisels. Depending on how the cutting rollers work, they are divided into axial (rotating in the direction of the support arm) and radial (across the support arm with two rollers) cutting machines. The latter can be used in harder rock or loosening blasts.

To back up

With the subsequent securing as an essential characteristic of the NET, a cavity-free, force-fit connection of the securing to the rock should be achieved. The core element is the application of shotcrete , with which the rock surface is tempered and a suitable composite structure between the rock and the concrete shell of the final construction is achieved. The shotcrete can be applied in two different methods:

- In the dry spray process, water is only added to a dry mixture (cement, aggregate, additive) at the spray nozzle.

- In the wet spray process, the finished concrete is already conveyed and mixed with air and additives at the spray nozzle.

Depending on the characteristics of the mountain, additional safety systems are built into the mountain or the shell. They are installed in advance of the actual eruption of the rock to improve the load-bearing capacity in loose rock or fissured rock: pawn sheets, spikes, pipe umbrellas, jet and injection umbrellas . What they have in common is that they should create or secure a composite effect in the rock in order to form the rock support ring around the tunnel cavity and to keep it stable.

After the excavation, if necessary, anchors are installed as dowels between the rock and concrete, which also support the formation of the rock support ring, or extension arches (steel or lattice girders with different profile shapes) are set up, which form the core of a surrounding concrete reinforcement and also to protect against falling rock fragments serve.

Skewers and pawns

Pawn sheets and (steel) skewers are simple mechanical securing devices that are rammed or drilled into the rock in a star shape around the excavated cross-section at an incline of 10 to 20 degrees to the tunnel axis. Deposit sheets are around 2 to 4 meters deep, skewers, mostly pipes with a diameter of up to 22 mm, are up to 5 meters long and are 30 to 50 cm apart. They can also be used in connection with injections , in which case perforated pipes are used in which the injection material is pressed into the surrounding ground, so that a stable injection body is created.

Tube umbrellas

Tube umbrellas are made from longer tubes up to 15 meters long with a diameter of 140 to 200 mm. Only the front section, up to 4 meters long, will be exposed later. Pipe umbrellas are often used to limit subsidence on the surface of the terrain.

Jet screens

Jet umbrellas have a similar load-bearing effect as pipe umbrellas, but consist of grouted boreholes. First a borehole is made and when the drill is slowly withdrawn, the soil is cut open with a grouting nozzle on the drill head and grouted while the drill rod is constantly rotating. Cylindrical, consolidated zones with a diameter of 50 to 100 cm are created.

Injection screens

Circumferential injections can also be used for stabilization by compressing the pore spaces so that the load-bearing capacity of the subsoil is increased and permeability is reduced.

icing

Icing screens can be used in the groundwater as a safety precaution if only a temporary increase in load-bearing capacity is required or if the permeability of the soil is to be temporarily reduced. The production of icing bodies - mostly with brine or liquid nitrogen - requires a high logistical effort and is therefore associated with considerable costs.

Accompanying measurements

The NET is linked to constant metrological checks, on the one hand to check the assumptions on which the tunneling is based, and on the other hand to check tensions and deformations after the installation of the first support means (usually the shotcrete shell) and in the dismantled state. Full measurement cross-sections with stress and deformation measurements are arranged at intervals of 200 m to 400 m, depending on the geological conditions, in urban areas under structures also significantly smaller, sometimes only 50 m. In between there is a network of points through which the deformation of the shell can be continuously observed.

application

The first practical application of NET using shotcrete took place in 1955 during tunnel construction work for the Prutz-Imst hydropower plant in Austria. In the Federal Republic of Germany it was used for the first time during the construction of the 308 m long double-track Schwaikheim tunnel in the Letten- and Gipskeuper between 1963 and 1965.

Between 1969 and 1971, the Frankfurt U-Bahn , construction lot 25, was the first to be a near-surface tunnel, which was built in the Frankfurt clay under development. In the following years, tunnels using this method were built at ever shorter intervals, such as the Hasenbuck tunnel from 1970 to 1971 and the A2 subway lot in Bochum from 1973 to 1975.

In the years that followed, NED became increasingly important in variously modified forms. In the case of the mined tunnels, their route share was already two thirds in 1983.

In the 1980s, the NET largely replaced the conventional construction methods used until then in the construction of long-distance railway and long-distance road tunnels. On the high-speed line Hanover – Würzburg , the first major new line of the German Federal Railroad , almost all of the 61 tunnels with a total length of around 121 km were built in accordance with the Lower Austrian Transport Authority, including the Landrückentunnel (10,779 m) and the Mündener Tunnel (10,525 m) two longest tunnels in Germany.

Example structures

The following prominent tunnels - in addition to the above-mentioned key projects - are constructed using this method:

- Transfer point in the English part of the Eurotunnel ("Probably one of the most impressive structures that has been built according to the principles of NATM" ())

- Himmelberg Tunnel (a railway tunnel on the high-speed line Cologne – Rhine / Main near Montabaur )

- Sitina Tunnel (a motorway tunnel in Slovakia )

- Dietershan tunnel (a railway tunnel on the high-speed line Hanover – Würzburg )

- Inntal Tunnel (a double-track railway tunnel between the Inntal and the Wipptal in Tyrol )

- Devil's Slide Tunnel (a road tunnel on California State Route 1 )

- Vomp – Terfens tunnel ( Lower Inn Valley Railway tunnel opened in 2011 )

- Gotthard Base Tunnel (a railway tunnel in Switzerland that crosses under the Alps)

literature

- Wulf Schubert, Georg M. Vavrovsky: The New Austrian Tunneling Method . ( pdf / https, online.tugraz.at [accessed on September 17, 2011] without images).

Individual evidence

- ↑ Dietmar Adam: Tunnel construction in solid and unconsolidated rock , Vienna University of Technology, PDF, 218 pages, 2016.

- ↑ a b c Friedrich Quellmelz: The New Austrian Tunneling Method . Bauverlag, Wiesbaden / Berlin 1987.

- ↑ Walter Wittke, Berndt Pierau, Clasu Erichsen: statics and construction of shotcrete . Verlag Glückauf, Essen 2002.

- ↑ Schweizerische Bauzeitung TEC21, May 23, 2014, No. 21–22, p. 24.

- ^ Franz Rziha: Textbook of the entire art of tunneling . tape I . Ernst & Korn, Vienna 1867 .; Franz Rziha: Textbook of the entire art of tunneling . tape II . Ernst & Korn, Vienna 1874.

- ↑ a b c d e f Wulf Schubert, Georg M. Vavrovsky: The New Austrian Tunneling Method . In: Austrian magazine for engineers and architects . Vienna 1996, p. 311-318 .

- ↑ a b c ÖIAV: New Austrian Tunneling Method, Definition and Principles . Ed .: Austrian Association of Engineers and Architects . Vienna 1980.

- ↑ German Society for Geotechnics e. V .: Recommendations of the "Tunneling" working group - ETB . Verlag Ernst & Sohn, Berlin 1995.

- ↑ Gerhard Grimscheid: Construction and construction in tunnel construction . 2nd Edition. Berlin 2008.

- ↑ Bernhard Maidl: Manual of tunnel and gallery construction, Volumes I and II . 3. Edition. Essen 2004.

- ↑ Historical photos of the construction of the Schwaikheim tunnel. Heimatverein Schwaikheim, accessed on August 28, 2011 .

- ↑ New Austrian Tunneling Method (NÖT). In: structurae . Retrieved September 17, 2011 .

- ↑ Tunnel construction, New Austrian. In: Austria Forum . Retrieved September 17, 2011 .

- ↑ A. Myers, M. John, D. Fugeman, M. Lafford, W. Purrer: Planning and execution of the British transfer point in the Channel Tunnel . In: Felsbau . tape 9 , no. 1 , 1991. Quoted in W. Schubert, GM Vavrovsky: Die Neue Österreichische Tunnelbaumethode . S. 11 .

- ↑ Because of Austria, Switzerland is through. In: news.ORF.at. May 31, 2016, accessed May 31, 2016 .